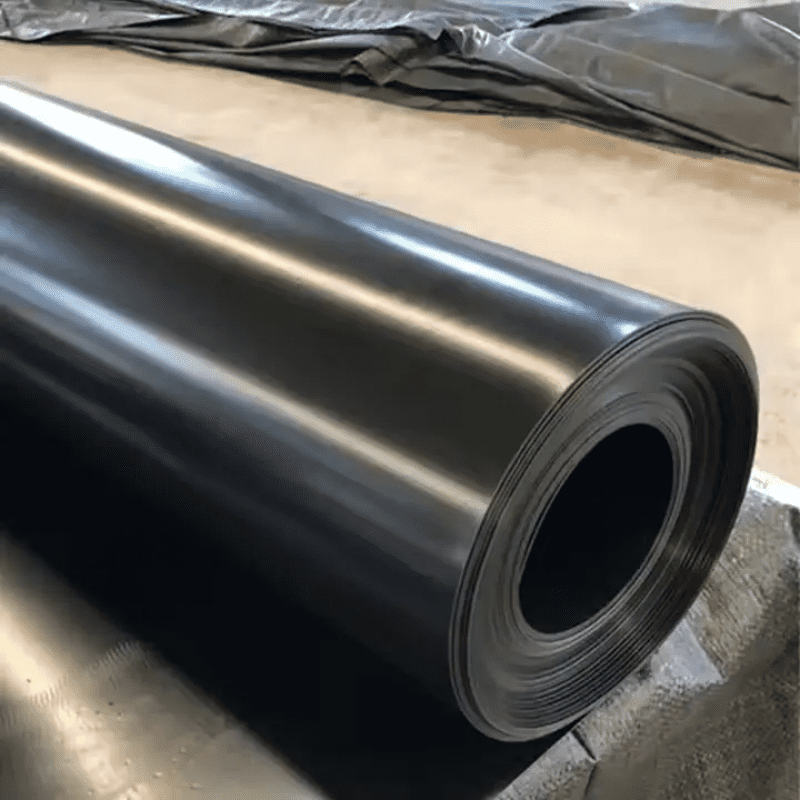

0.75mm HDPE Geomembrane

1.Superior Waterproofing Provides an effective impermeable barrier to prevent water, leachate, and chemical leakage.

2.Enhanced Mechanical Strength Thicker material resists punctures and tears on rough subgrades or under heavy loads.

3.Ideal Thickness for Versatile Use Perfect for projects needing more durability than 0.5mm but less weight than 1.0mm.

4.UV & Chemical Resistance Withstands harsh weather and corrosive environments for long-lasting performance.

5.Reliable Seam Welding Supports strong thermal welding for secure, leak-proof connections.

0.75mm HDPE Geomembrane

In the modern era of industrial expansion and environmental awareness, geomembranes have emerged as critical components in civil engineering, agriculture, and waste management. Among them, the 0.75mm HDPE geomembrane stands out for its optimal balance between flexibility and durability. Widely recognized for its impermeability and chemical resistance, this material is commonly used for lining projects that demand environmental safety and long-term performance.

What is a 0.75mm HDPE Geomembrane?

A geomembrane is a synthetic membrane liner or barrier with very low permeability, used to control fluid or gas migration in a human-made project or system. HDPE, or High-Density Polyethylene, is one of the most popular materials for geomembrane production due to its strength, flexibility, and resistance to UV rays and chemicals.

The 0.75mm thickness (or 30 mil) is a mid-range specification, ideal for many general lining projects. It is thick enough to provide significant durability against punctures and tears, while still being light and flexible enough for easy handling and installation.

Properties and Advantages

The 0.75mm HDPE geo membrane offers several advantageous properties:

Excellent Chemical Resistance: It withstands acids, alkalis, and hydrocarbons, making it suitable for industrial and hazardous waste containment.

UV and Ozone Resistance: Unlike other plastics, HDPE geomembranes can be exposed to sunlight for extended periods without significant degradation.

Flexibility: While thicker liners may be stiffer, 0.75mm geomembranes offer a good compromise, retaining flexibility without sacrificing strength.

Long Service Life: In buried applications, the lifespan can exceed 50 years, depending on site conditions.

Puncture Resistance: The material’s mechanical properties allow it to resist root penetration, abrasion, and impact, making it a reliable containment barrier.

Applications of 0.75mm HDPE Geomembrane

Thanks to its performance characteristics, the 0.75mm geomembrana in HDPE is used in a wide range of industries and infrastructure projects, including:

Landfills and Waste Management Sites: Used as bottom liners and capping systems to prevent leachate contamination of soil and groundwater.

Mining Industry: Serves as a liner for tailings ponds, heap leach pads, and evaporation ponds, ensuring containment of toxic materials.

Agricultural Ponds and Canals: Prevents water seepage in irrigation systems and reservoirs.

Aquaculture: Used in fish farming tanks and ponds to create a sterile, leak-proof environment.

Construction and Civil Engineering: Acts as a vapor barrier or waterproofing layer in road construction, tunnels, and basements.

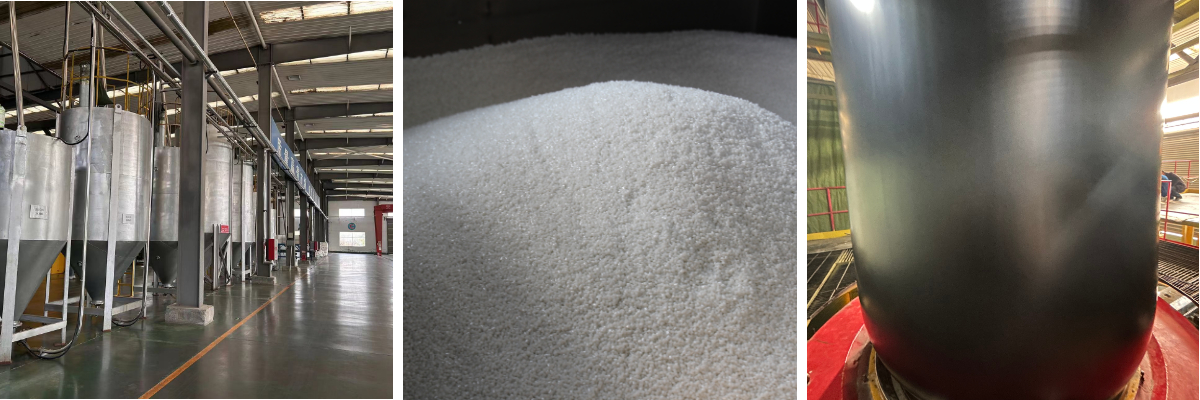

HDPE Geomembrane Line: How It’s Made

The production of HDPE geomembrane is a highly controlled process using advanced extrusion technology. A typical HDPE geomembrane line includes the following key stages:

Raw Material Feeding: Virgin HDPE resin, often combined with carbon black and antioxidant additives, is fed into the extruder.

Extrusion: The resin is melted and passed through a die to form a continuous sheet. The process can follow either a blown film or calendering method.

Cooling and Sizing: The molten sheet is cooled using water baths or rollers and trimmed to desired width and thickness.

Texturing (optional): To enhance friction and anchorage, a textured surface can be applied on one or both sides.

Winding and Storage: The final product is rolled and stored in a clean, dry environment, ready for shipment.

Advanced HDPE geomembrane lines are often fully automated and integrated with real-time quality control systems to ensure uniform thickness and strength throughout the product.

Installation and Quality Control

Even the best geomembrane must be correctly installed to perform its intended function. Installation involves site preparation, unrolling, positioning, seaming (usually by hot wedge welding), and testing. Quality assurance includes visual inspection, non-destructive testing of seams, and sometimes destructive testing of samples to verify performance parameters.

Third-party certifications and lab reports often accompany HDPE geomembranes to validate compliance with international standards such as ASTM and GRI-GM13.

Environmental Impact and Sustainability

Using HDPE geo membrane liners significantly reduces the risk of environmental contamination. As a recyclable material, HDPE contributes to sustainability goals. Modern manufacturing facilities aim to reduce waste and energy consumption, while products made with 100% virgin resin ensure long-lasting performance without harmful leaching or degradation.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

The 0.75mm geomembrana in HDPE is a versatile, cost-effective, and reliable choice for a wide range of containment and lining projects. With growing emphasis on environmental protection and infrastructure resilience, demand for high-quality HDPE geomembranes continues to rise globally. For project developers and engineers, choosing a trusted supplier with advanced production capabilities and proven material performance is essential.

Whether used in landfill engineering, aquaculture, or mining, the 0.75mm HDPE geomembrane exemplifies how engineered materials can support both development and environmental stewardship.