HDPE Tailing Pond Liner

1.Excellent Chemical Resistance – Effectively resists acids, alkalis, and industrial contaminants.

2.High Puncture Strength – Withstands sharp tailings and rough subgrade surfaces.

3.UV and Weather Resistant – Maintains performance under long-term outdoor exposure.

4.Superior Impermeability – Prevents seepage and protects groundwater.

5.Long Service Life – Durable material ensures stable containment for decades.

6.Easy Installation and Welding – Supports fast deployment with reliable seam strength.

HDPE Tailing Pond Liner

In the modern mining and metallurgical industries, the containment of tailings and process water is a critical environmental responsibility. Tailing ponds must be designed not only for capacity and safety but also to prevent the leaching of hazardous substances into the surrounding soil and groundwater. One of the most effective and widely used solutions for lining these ponds is the High-Density Polyethylene (HDPE) geomembrane liner. With its exceptional durability, chemical resistance, and impermeability, the HDPE tailing pond liner has become the gold standard in tailings management across mining operations worldwide.

What is HDPE Tailing Pond Liner?

An HDPE tailing pond liner is a high-performance geomembrane made from high-density polyethylene resin. It is engineered to serve as a reliable barrier between contaminated tailings and the natural environment. The liner’s function is to contain slurry, wastewater, and solid waste produced by mining activities, preventing them from seeping into surrounding ecosystems.

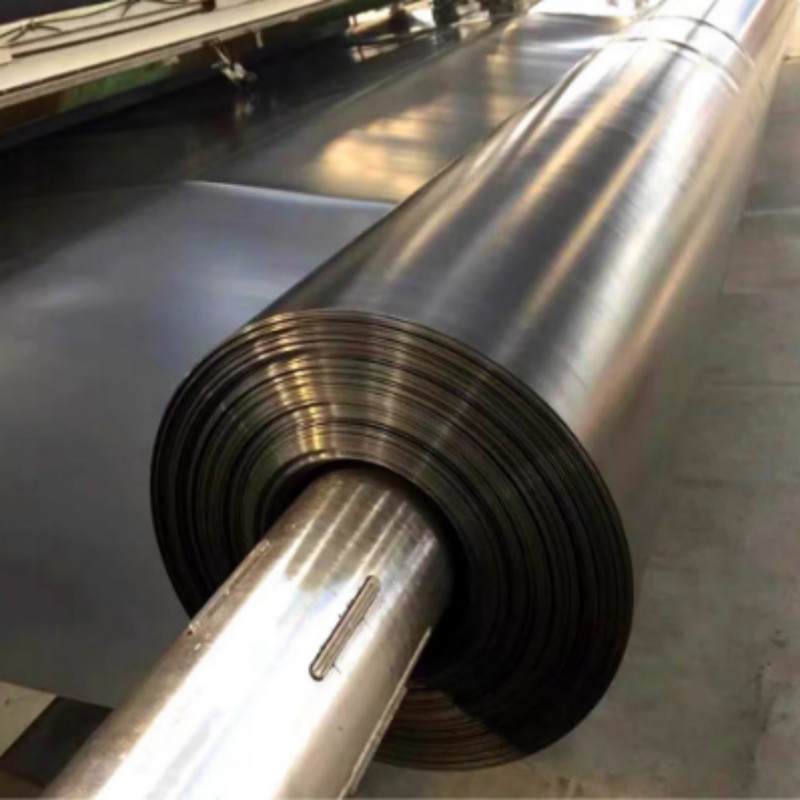

These liners are typically manufactured in rolls, with thicknesses ranging from 0.5mm to 3.0mm depending on project requirements. The most common choices for tailings containment are 1.5mm and 2.0mm thicknesses, offering a balance of flexibility and strength.

Key Advantages of HDPE Tailing Pond Liner

1. Exceptional Chemical Resistance

Tailings often contain highly corrosive substances, including heavy metals, acids, and industrial salts. HDPE liners are chemically inert and provide outstanding resistance to a wide range of aggressive chemicals. This makes them ideal for use in mining operations where chemical exposure is inevitable.

2. High Tensile and Puncture Strength

HDPE geomembranes are designed to endure the challenging conditions of tailing ponds. They offer superior tensile strength and puncture resistance, capable of withstanding heavy loads, sharp rocks, and mechanical stresses. This ensures structural integrity even under extreme conditions.

3. Superior Impermeability

The most critical function of a tailing pond liner is to block any fluid or gas migration. HDPE liners provide near-zero permeability, preventing any leakage of process fluids or contaminants into the subsurface. This helps protect nearby water bodies, agricultural land, and the health of local communities.

4. UV and Weather Resistance

Tailing ponds are often exposed to harsh sunlight and varying weather conditions. HDPE geomembranes are UV-stabilized and can resist degradation from ultraviolet exposure, ozone, and temperature fluctuations. This property extends the service life of the liner, even in desert or high-altitude environments.

5. Long-Term Durability

HDPE liners are built to last. When properly installed and maintained, they can offer a service life of more than 20 to 30 years. This long lifespan reduces the need for frequent replacements and lowers overall maintenance costs.

6. Easy Installation and Welding

HDPE liners are flexible and compatible with heat fusion welding. The seams formed during installation are strong, leak-proof, and consistent across large areas. This ensures quick and secure installation, minimizing labor time and risks of seam failure.

Applications Beyond Tailing Ponds

While HDPE geomembranes are most commonly associated with tailing ponds, their application range extends beyond mining:

1.Heap leach pads

2.Process water ponds

3.Sludge and residue containment

4.Landfills

5.Industrial wastewater lagoons

Their versatility makes them a preferred material in industries such as mining, petrochemicals, power generation, and construction.

Why Choose Haoyang as Your HDPE Liner Supplier?

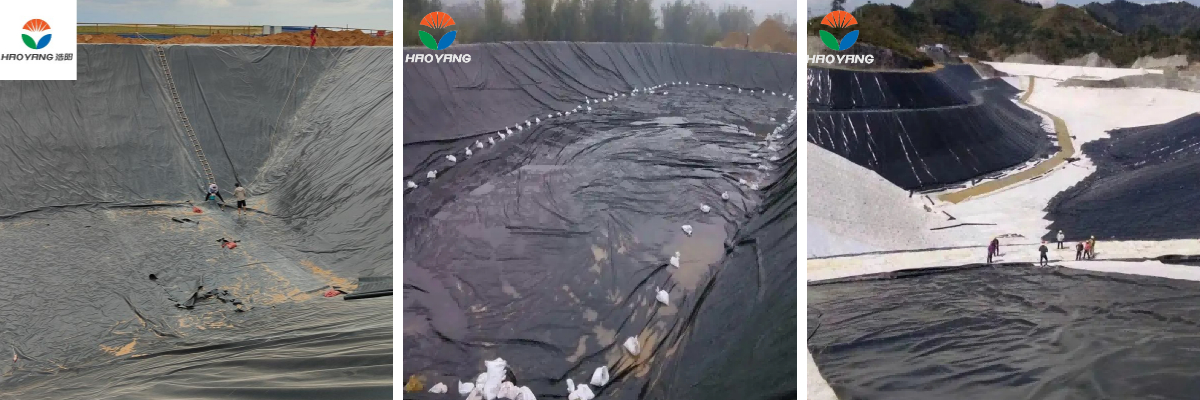

Haoyang Environmental Co., Ltd is a trusted manufacturer and direct supplier of HDPE geomembrane liners. With state-of-the-art production equipment, 100% virgin raw materials, and strict quality control standards, Haoyang ensures that each roll of liner meets international specifications such as GM13 standards.

Our tailing pond liners have been successfully installed in government projects, mining operations, and environmental restoration efforts across Asia, Africa, South America, and the Middle East.

Haoyang offers:

1.Customizable thicknesses and roll sizes

2.Technical support and installation guidance

3.Factory-direct pricing and timely delivery

4.Compliance with ISO9001 and CE certifications

By choosing Haoyang, clients receive not just a product, but a reliable environmental solution backed by professional engineering and service.

Environmental Responsibility and Regulation Compliance

Governments and environmental authorities are increasingly enforcing stricter regulations for tailings disposal. Improper containment can result in serious legal consequences, environmental disasters, and reputational damage. Using a high-quality HDPE liner significantly reduces the risk of tailing pond failures and supports compliance with international safety and environmental standards.

From a sustainability perspective, HDPE liners contribute to the responsible use of land and water resources. By preventing leakage and contamination, they safeguard natural ecosystems and promote more sustainable mining practices.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

As the mining industry continues to grow, so does the need for safe, efficient, and environmentally sound waste management solutions. The HDPE tailing pond liner stands out as a proven technology that delivers performance, reliability, and cost-effectiveness. Whether for gold mining in Africa, copper tailings in South America, or rare earth processing in Asia, HDPE geomembranes play an essential role in protecting the environment and ensuring regulatory compliance.

For mining companies, contractors, and environmental engineers seeking a high-quality lining solution, Haoyang offers the expertise, product quality, and global service capabilities to meet even the most demanding project requirements.