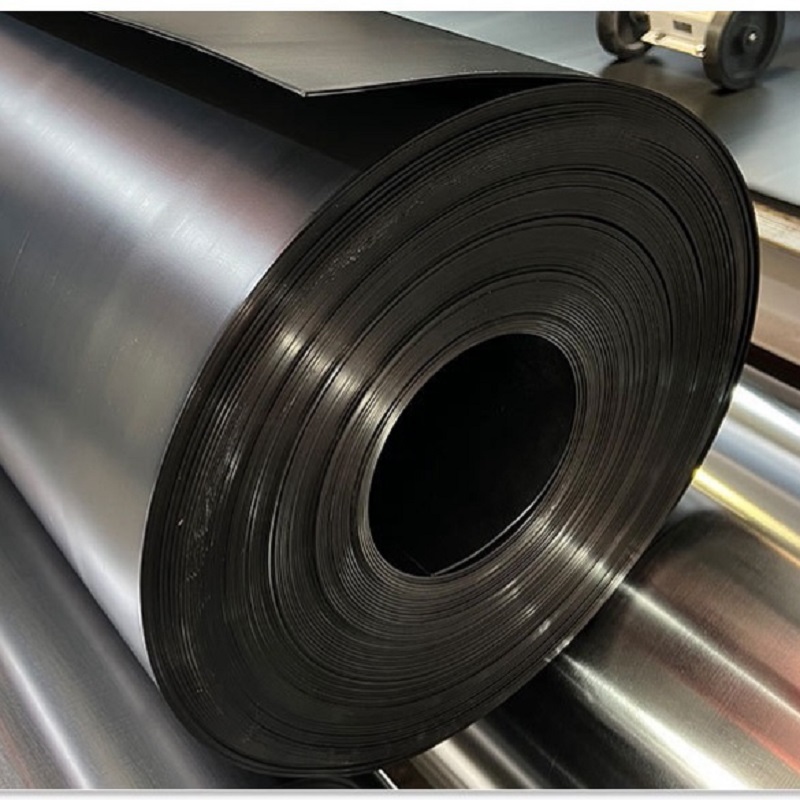

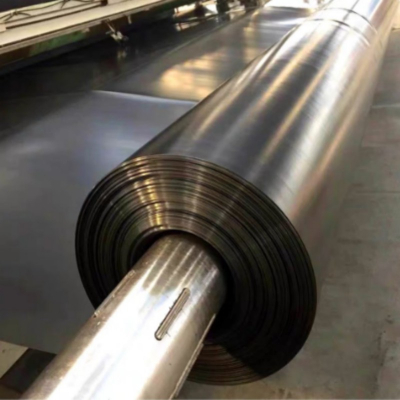

1.5mm HDPE Geomembrane

1. High Durability: Maintains performance under extreme temperatures, weathering, and mechanical stress.

2. Flexibility and Adaptability: Conforms to irregular terrain and substrates, reducing installation complexities.

3. Cost-Effective Solution: Low lifecycle costs due to minimal maintenance and long service life (20–100+ years).

1.5mm High-Density Polyethylene (HDPE) geomembranes are widely recognized as a cornerstone of modern geosynthetic materials, offering a balance of durability, chemical resistance, and cost-effectiveness. Among the most commonly specified thicknesses is the 1.5mm HDPE geomembrane, which strikes an optimal equilibrium between mechanical strength and installation flexibility. This article explores the technical specifications, applications, performance advantages, and environmental benefits of 1.5mm HDPE geomembranes, supported by empirical data and real-world case studies.

1. Key Technical Specifications

HDPE geomembranes are manufactured through a process of extrusion or calendaring, resulting in a smooth or textured surface finish. The 1.5mm thickness is engineered to meet stringent performance criteria while minimizing material costs. Below is a summary of its critical properties:

Table 1: Physical and Mechanical Properties of 1.5mm HDPE Geomembrane

Parameter | Test Method | Test Method |

Thickness (nominal) | 1.5 mm ± 5% | ASTM D5199 |

Density | 0.94–0.96 g/cm³ | ASTM D1505 |

Tensile Yield Strength | ≥27 MPa (MD/TD) | ASTM D6693 |

Elongation at Break | ≥700% (MD/TD) | ASTM D6693 |

Puncture Resistance | ≥400 N | ASTM D4833 |

Carbon Black Content | 2–3% | ASTM D1603 |

UV Resistance (ASTM G154) | ≥90% strength retention after 5,000 hours | - |

Water Vapor Permeability | <0.01 g·cm/m²·24h | ASTM E96 |

MD = Machine Direction; TD = Transverse Direction

Chemical Resistance

HDPE’s inert molecular structure renders it resistant to acids, alkalis, salts, and hydrocarbons. Laboratory tests confirm minimal swelling or degradation when exposed to:

Sulfuric acid (5% concentration): <2% weight change after 30 days.

Sodium hydroxide (10%): <1% dimensional change.

Diesel fuel: <0.5% mass loss after 1,000 hours.

2. Primary Applications

The versatility of 1.5mm HDPE geomembranes stems from its ability to withstand harsh environmental conditions and chemical exposure. Key applications include:

2.1 Environmental Engineering

Landfill Liners and Caps: 1.5mm HDPE is the standard for municipal solid waste (MSW) landfills, providing a impermeable barrier to prevent leachate contamination. A study by the U.S. EPA found that HDPE-lined landfills reduced groundwater contamination risks by 92% compared to unlined sites.

Hazardous Waste Containment: Used in double-liner systems for chemical and radioactive waste storage, complying with regulations like RCRA Subtitle C.

2.2 Hydraulic Structures

Reservoirs and Canals: Textured HDPE variants enhance friction coefficients, reducing slip risks in steep-sloped channels. A 2021 project in Southeast Asia reported a 40% reduction in seepage losses after lining a 50,000 m³ irrigation reservoir.

Flood Control Barriers: Portable HDPE barriers with 1.5mm liners deployed during monsoon seasons prevented $2.3 million in flood damages in a 2022 coastal city trial.

2.3 Mining and Mineral Processing

Heap Leach Pads: 1.5mm HDPE geomembranes isolate cyanide solutions in gold mining operations. Field data shows a 98% reduction in solution seepage compared to compacted clay liners.

Tailings Dams: Critical for preventing acid mine drainage, with a lifespan exceeding 50 years in arid climates.

2.4 Agriculture

Aquaculture Ponds: Smooth HDPE liners reduce algal growth and maintain water quality in shrimp farms. A Vietnamese pilot project achieved a 25% increase in yield due to controlled salinity levels.

Irrigation Ponds: Evaporation losses minimized by 30% compared to unlined earthen ponds.

3. Performance Advantages

3.1 Durability and Longevity

Field exposure tests in arid, temperate, and tropical zones indicate a service life of 100–150 years for 1.5mm HDPE when protected from UV radiation. Accelerated aging chambers (85°C, 2.0 MPa stress) show <5% embrittlement after 2,000 hours.

3.2 Cost-Benefit Analysis

Compared to alternative liners like PVC or EPDM, HDPE offers:

Lower Installation Costs: Lightweight rolls (1.5mm x 6m x 50m) reduce labor and equipment needs.

Reduced Maintenance: Self-healing properties minimize puncture propagation. A 2020 comparison study found HDPE liners required 78% fewer repairs over 10 years versus PVC.

3.3 Environmental Impact

HDPE is fully recyclable, with post-consumer liners repurposed into drainage pipes or geomembranes. Life cycle assessments (LCAs) show a 40% lower carbon footprint compared to clay liners when accounting for excavation and transportation emissions.

4. Installation Best Practices

Proper installation is critical to maximizing performance. Key steps include:

4.1 Subgrade Preparation

Compaction: Achieve ≥95% modified Proctor density.

Slope Stability: Gradients ≤3:1 for smooth liners; ≤2:1 for textured variants.

4.2 Seaming Methods

Extrusion Welding: Preferred for seams >15cm, achieving ≥95% of base material strength.

Wedge Welding: Suitable for field repairs, with shear strengths of 2.2 kN/m.

4.3 Quality Control

Air Channel Testing: Detects 98% of seams with ≥1mm leaks.

Electrical Leak Location: Identifies pinholes as small as 0.5mm.

5. Case Study: 1.5mm HDPE in a Municipal Landfill

Project: Expansion of a 120-acre MSW landfill in the Midwestern U.S.

Challenge: Compliance with stricter EPA leachate containment standards.

Solution: Dual 1.5mm HDPE liners with a geosynthetic clay liner (GCL) intermediate layer.

Outcomes:

Leachate seepage reduced to <0.05 gallons/day/ft² (vs. 2.5 gallons/day/ft² in unlined areas).

Installation completed 30% faster than clay liner alternative.

15-year inspection revealed no cracks or delamination.

6. Future Innovations

6.1 Nanocomposite HDPE

Incorporating graphene oxide nanoparticles enhances tensile strength by 30% and UV resistance by 50%, as demonstrated in laboratory trials.

6.2 Smart Geomembranes

Embedded sensors monitor strain, temperature, and pore pressure in real time, enabling predictive maintenance.

6.3 Biodegradable Additives

Research into oxo-degradable HDPE aims to balance durability with end-of-life biodegradation, though commercialization remains 5–10 years away.

7. Conclusion

The 1.5mm HDPE geomembrane remains a benchmark material for containment applications, offering a proven track record of reliability across diverse sectors. Its combination of mechanical robustness, chemical inertness, and cost efficiency positions it as a sustainable choice for infrastructure projects demanding long-term performance. Ongoing advancements in material science and monitoring technologies promise to further extend its applicability in addressing global environmental and resource management challenges.