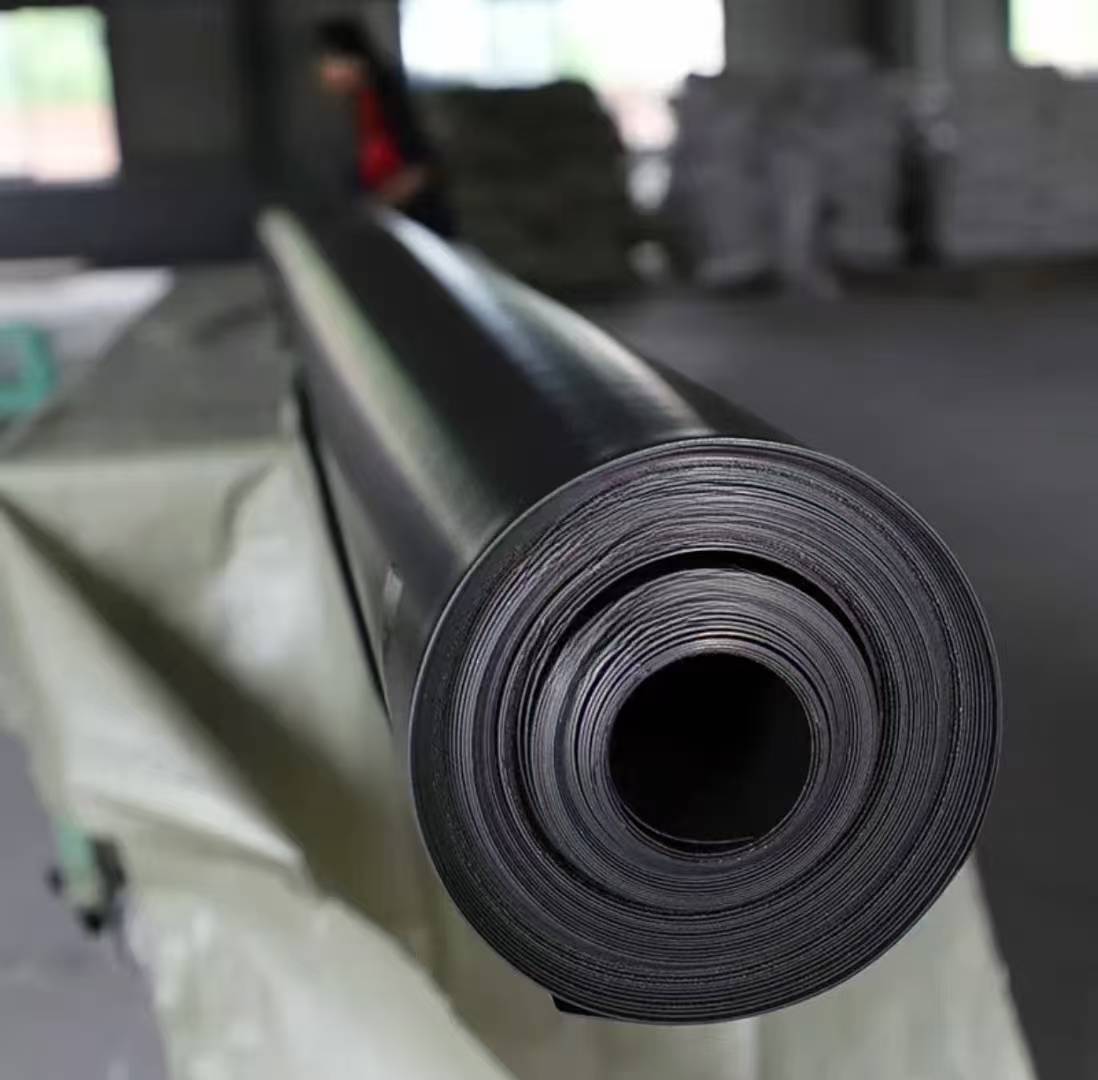

1.2mm HDPE Dam Liner

1.Superior Seepage Control-Excellent anti-seepage performance and long-lasting durability

2.High Strength-Strong tensile strength and puncture resistance ensure reliability

3.Weather & Chemical Resistant-UV and chemical resistance for demanding environments

4.Flexible Installation-Adapts easily to uneven or irregular surfaces

5.Premium Material-Made from 100% virgin HDPE for consistent, high quality

6.Proven Results-Widely used and trusted in large-scale dam and pond projects

1.2mm HDPE Dam Liner

In modern water management and environmental engineering, the choice of lining materials plays a decisive role in ensuring long-term project success. Among the various solutions available, the 1.2mm HDPE Dam Liner has emerged as an industry standard for its exceptional performance, durability, and cost-effectiveness. Combining superior anti-seepage properties with excellent resistance to environmental stress, this liner is widely used in dam projects, reservoirs, aquaculture ponds, canals, and other critical containment applications.

Why Choose a 1.2mm HDPE Dam Liner?

At the heart of any water containment project is the need for a reliable barrier that prevents seepage, withstands external forces, and remains stable over many years. The 1.2mm HDPE Dam Liner meets these requirements through a balanced design of thickness, material quality, and structural flexibility.

Superior Anti-Seepage Performance

The primary function of a dam liner is to prevent water loss. With a thickness of 1.2mm, the HDPE liner offers a highly effective barrier against water seepage. This performance is critical in maintaining reservoir capacity, protecting nearby land and infrastructure, and reducing operational costs associated with water loss.

Excellent Strength and Puncture Resistance

Constructed from high-density polyethylene (HDPE), the liner exhibits impressive tensile strength and puncture resistance. This ensures that it can withstand mechanical stress from sharp stones, construction equipment, and fluctuating water pressures. Even in challenging installation environments, the 1.2mm liner retains its integrity.

UV and Chemical Resistance

Outdoor water containment structures are continuously exposed to sunlight and may come into contact with various chemicals in soil and water. The HDPE material is inherently resistant to UV radiation and chemical degradation. This significantly extends the liner’s service life, reducing the frequency and cost of repairs and replacements.

Adaptable and Easy to Install

Despite its robust structure, the 1.2mm HDPE Dam Liner remains flexible enough to adapt to the contours of dams and ponds. It can be welded seamlessly on-site to form large, continuous sheets, which enhances the anti-seepage effect and speeds up installation.

Made from Virgin Material for Consistent Quality

At Haoyang Environmental Co., Ltd., we manufacture our liners using 100% virgin HDPE resin. This commitment ensures consistent quality, uniform thickness, and reliable performance across every project. Our products meet international standards and have been successfully applied in numerous government and private sector projects worldwide.

Applications Beyond Dams

While named a “Dam Liner,” the versatility of the 1.2mm HDPE liner extends far beyond dams. Common applications include:

1.Reservoirs and water storage ponds – ensuring stable water levels for irrigation and municipal use.

2.Canals and channels – preventing seepage into surrounding soil and protecting structural integrity.

3.Aquaculture ponds – maintaining clean water conditions and reducing disease risk.

4.Landfill cells and capping systems – acting as a reliable barrier to isolate waste and prevent contamination.

5.Mining tailings ponds – controlling seepage of contaminated water and chemicals.

The adaptability of the HDPE liner makes it a preferred solution in industries as diverse as agriculture, mining, waste management, and construction.

Key Features at a Glance

For quick reference, here are some of the standout features of our 1.2mm HDPE Dam Liner:

1.Superior Seepage Control: Effectively prevents water leakage and soil erosion.

2.High Strength: Excellent tensile strength and puncture resistance ensure durability.

3.Weather & Chemical Resistant: Performs reliably under harsh sun exposure and in chemically active environments.

4.Flexible Installation: Can be installed on slopes, curves, and uneven ground.

5.Premium Material: Produced with virgin HDPE for consistent performance.

6.Long Service Life: Designed to perform for decades with minimal maintenance.

Commitment to Quality and Service

At Haoyang Environmental Co., Ltd., we understand that choosing the right liner is only part of the equation. Equally important is working with a partner who offers expertise, technical support, and reliable logistics.

1.Customized Solutions: We can supply liners in rolls of various widths and lengths to suit the specific dimensions of your project, minimizing waste and installation time.

2.Professional Installation Guidance: Our experienced technical team can provide on-site training and installation guidance to ensure proper seam welding and testing.

3.Strict Quality Control: Every liner undergoes rigorous testing for thickness, tensile strength, tear resistance, and impermeability before leaving our factory.

4.Export Experience: With years of export experience, we serve clients worldwide, supporting projects in Asia, Africa, the Middle East, and beyond.

Why Thickness Matters

When selecting an HDPE liner, the choice of thickness depends on factors like water depth, soil conditions, and mechanical loads. A 1.2mm thickness strikes a balance between cost-effectiveness and performance. It offers greater puncture resistance and durability compared to thinner options (e.g., 0.75mm or 1.0mm), while remaining easier to handle and weld than thicker liners (e.g., 1.5mm or 2.0mm).

This makes the 1.2mm HDPE Dam Liner a popular choice for medium to large-scale water storage projects where a long service life and moderate mechanical strength are required.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Partnering for Long-Term Success

Large-scale water containment projects are significant investments that must stand the test of time. Choosing the right liner is about more than technical specifications — it’s about working with a trusted manufacturer who understands your challenges and offers reliable, high-quality solutions.

At Haoyang Environmental Co., Ltd., we’re proud to be that partner. From dam liners to landfill liners, our HDPE geomembrane products have earned the trust of engineers, contractors, and government agencies worldwide.

If you’re planning a dam, reservoir, aquaculture pond, or similar project, our team is ready to help. Contact us today to learn more about how our 1.2mm HDPE Dam Liner can add long-term value to your project.