0.8mm HDPE Dam Liner

1.Excellent Anti-Seepage – Made from high-density polyethylene with a very low permeability coefficient, ensuring outstanding leak prevention.

2.Long Service Life – Superior resistance to UV radiation and oxidation makes it suitable for long-term outdoor use.

3.High Tensile Strength – Strong tensile properties and good elongation at break allow it to adapt to uneven settlement and ground deformation.

4.Chemical Resistance – Excellent resistance to acids, alkalis, and salts, ideal for applications like landfills and chemical containment ponds.

5.Efficient Installation – Available in large roll widths with fewer seams; supports hot-melt welding for faster, more secure installation.

0.8mm HDPE Dam Liner

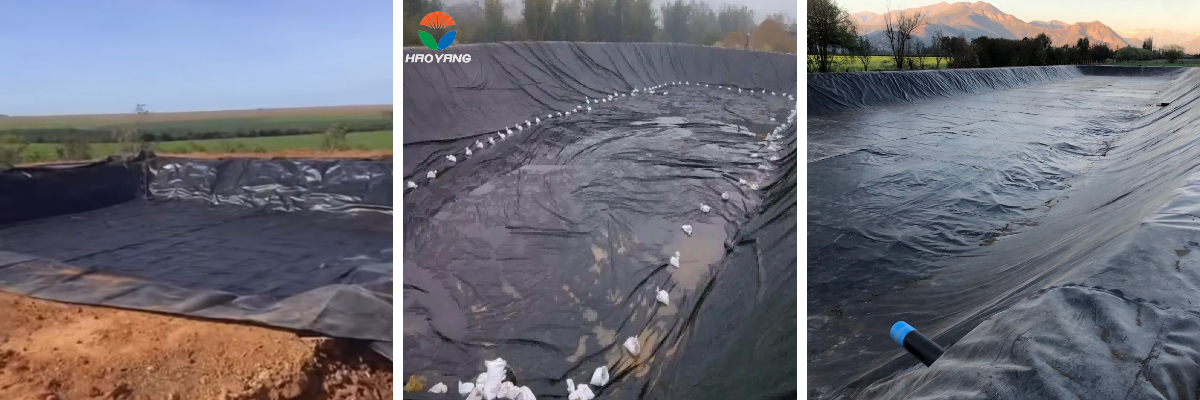

In water containment engineering, preventing seepage is critical to protect resources and infrastructure. The 0.8mm HDPE dam liner, made from high-density polyethylene, offers an exceptionally low permeability coefficient thanks to its dense molecular structure. This ensures that water stored in dams, ponds, and reservoirs remains effectively sealed, reducing loss and preventing contamination of nearby soil and groundwater. Such reliable performance is especially valuable in agricultural irrigation ponds, aquaculture projects, and industrial water storage facilities, where consistent water levels and quality directly affect productivity and safety.

Outstanding Durability and Weather Resistance

Durability under harsh conditions is one of the defining advantages of the 0.8mm HDPE dam liner. Produced from virgin HDPE resins, it resists environmental stress cracking, punctures, and mechanical wear. Its excellent tensile strength and flexibility help the liner withstand soil settlement and minor ground movement without tearing.

Moreover, its superior UV resistance means it can be used in outdoor environments where long-term sunlight exposure is unavoidable. Even in regions with high solar radiation or extreme weather changes, the liner maintains its performance, offering a service life often exceeding 20 years. This makes it a cost-effective choice, requiring fewer repairs and replacements over time.

Superior Chemical and Biological Resistance

Another significant benefit of the 0.8mm HDPE dam liner is its resistance to chemical corrosion. It remains stable when exposed to acids, alkalis, and salts, commonly present in soil, industrial effluents, or agricultural runoff. This ensures that the liner continues to protect stored water and surrounding areas, even under chemically challenging conditions.

In addition, the HDPE material naturally resists microbial and fungal growth. This feature is crucial in aquaculture and irrigation projects, where maintaining water purity supports healthier fish stocks and better crop yields, reducing the need for chemical treatments or frequent cleaning.

Efficient Installation and Seam Reliability

The design of the 0.8mm HDPE dam liner makes it practical and efficient to install. Supplied in large rolls—often 5–8 meters wide and up to 100 meters long—it reduces the number of seams needed, saving time and installation costs.

The moderate 0.8mm thickness provides an ideal balance between flexibility and mechanical strength. It easily adapts to curved or uneven subgrades, making it suitable for projects of varying shapes and sizes. Professional installation uses hot-melt or hot wedge welding, producing strong, homogeneous seams as durable as the liner itself. This ensures long-lasting, leak-proof joints that protect water resources even under pressure.

Environmentally Friendly and Sustainable

Sustainability is increasingly important in engineering choices, and the 0.8mm HDPE dam liner aligns well with this priority. Manufactured from 100% virgin, food-grade HDPE, it contains no toxic additives, making it safe for fish farming, irrigation, and drinking water projects.

Its impermeability not only prevents water waste but also protects surrounding ecosystems from contamination by stored liquids. At the end of its service life, the liner can be fully recycled, reducing landfill waste and supporting circular economy practices. These qualities make it a responsible choice for environmentally conscious projects.

Versatility Across Industries

The applications of the 0.8mm HDPE dam liner go beyond dams alone. In agriculture, it helps conserve irrigation water and supports reliable crop production. In aquaculture, it creates clean, stable pond environments, improving stock health and reducing disease risk. Industrial projects rely on its chemical resistance for process water ponds and chemical storage areas. Even landfill operators use the liner to cap sites and contain leachate, preventing environmental harm.

Its adaptability makes it an excellent investment for engineers and contractors working across multiple sectors, providing a single, proven solution for diverse containment challenges.

Cost-Effectiveness and Long-Term Value

Choosing the 0.8mm HDPE dam liner often comes down to its balance of price and performance. While thinner than some heavy-duty liners, it still delivers excellent mechanical and chemical resistance for medium-duty projects, offering significant material cost savings.

Faster installation, reduced maintenance, and a long lifespan further lower total project costs. Over time, the reduction in water loss, fewer repairs, and improved efficiency can more than offset the initial investment, making it a smart financial decision for large and small projects alike.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Conclusion: A Smart Choice for Sustainable Water Management

The 0.8mm HDPE dam liner combines impermeability, durability, chemical resistance, and environmental friendliness in one versatile solution. Its proven performance protects critical water resources, supports sustainable practices, and offers long-term savings.

From agricultural ponds to industrial reservoirs and landfill covers, this liner helps meet today’s water management and environmental challenges confidently and efficiently. As the demand for reliable and eco-friendly engineering materials grows, the 0.8mm HDPE dam liner continues to stand out as a trusted choice for modern projects worldwide.