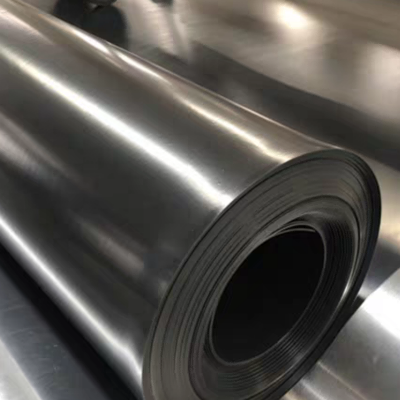

HDPE Geo Membrane

Superior Impermeability – Ultra-low permeability (<1×10⁻¹³ cm/s) prevents leakage of liquids, gases, and contaminants.

Chemical Resistance – Withstands acids, alkalis, salts, and solvents; ideal for hazardous environments.

Long Lifespan – UV/oxidation resistant, performs from -60°C to 80°C, with 50+ years of durability.

High Strength – Excellent tensile (20–40 MPa) and puncture resistance for demanding applications.

Cost Efficiency – Fast installation (thermal welding), low maintenance, and superior longevity over clay/concrete.

Product Introduction

HDPE Geomembrane is a high-density polyethylene synthetic liner used as a fluid/gas barrier in engineering and environmental projects.Commonly applied in landfills, mining, water containment, and pollution control.

Product Specifications

Properties | Test Method | GM13 Test Value | Testing Frequency | ||||||

Thickness (min. ave.) | 0.75mm | 1mm | 1.25mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | (minimum) | |

nom. | nom. | nom. | nom. | nom. | nom. | nom. | Per roll | ||

lowest individual of 10 values | D5199 | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |

Formulated Density mg/l (min.) | D 1505/ D 792 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 90,000kg |

Tensile Properties (1) (min. ave.) | D 6693 Type IV | 9,000kg | |||||||

. yield strength | 11kn/m | 15kn/m | 18kn/m | 22kn/m | 29kn/m | 37kn/m | 44kn/m | ||

. break strength | 20kn/m | 27kn/m | 33kn/m | 40kn/m | 53kn/m | 67kn/m | 80kn/m | ||

. yield elongation | 12% | 12% | 12% | 12% | 12% | 12% | 12% | ||

. break elongation | 700% | 700% | 700% | 700% | 700% | 700% | 700% | ||

Tear Resistance (min. ave.) | D 1004 | 93N | 125N | 156N | 187N | 249N | 311N | 374N | 20,000 kg |

Puncture Resistance (min. ave.) | D 4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N | 20,000 kg |

Stress Crack Resistance (2) | D5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | per GRI-GM10 |

(App.) | |||||||||

Carbon Black Content (range) | D 4218 (3) | 2.0-3.0% | 9,000kg | ||||||

Oxidative Induction Time (OIT) (min. ave.) (5) (a) Standard OIT | D 3895 D 5885 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 90,000kg |

— or —(b) High Pressure OIT | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | ||

Oven Aging at 85°C (5), (6) | D 5721 D 3895 D 5885 | per each formulation | |||||||

(a) Standard OIT (min. ave.) - % retained after 90 days — or — | 55% | 55% | 55% | 55% | 55% | 55% | 55% | ||

(b) High Pressure OIT (min. ave.) - % retained after 90 days | 80% | 80% | 80% | 80% | 80% | 80% | 80% | ||

(a) Standard OIT (min. ave.) | D 3895 D 5885 | 50% | 50% | 50% | 50% | 50% | 50% | 50% | per each formulation |

— or — | |||||||||

(b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | |||||||||

Types of HDPE Geomembrane

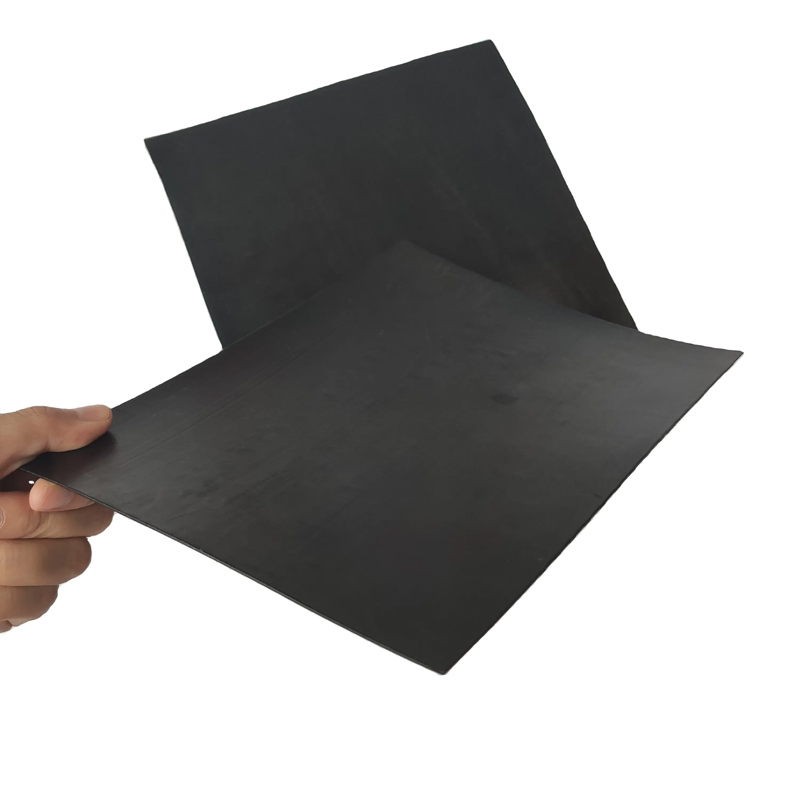

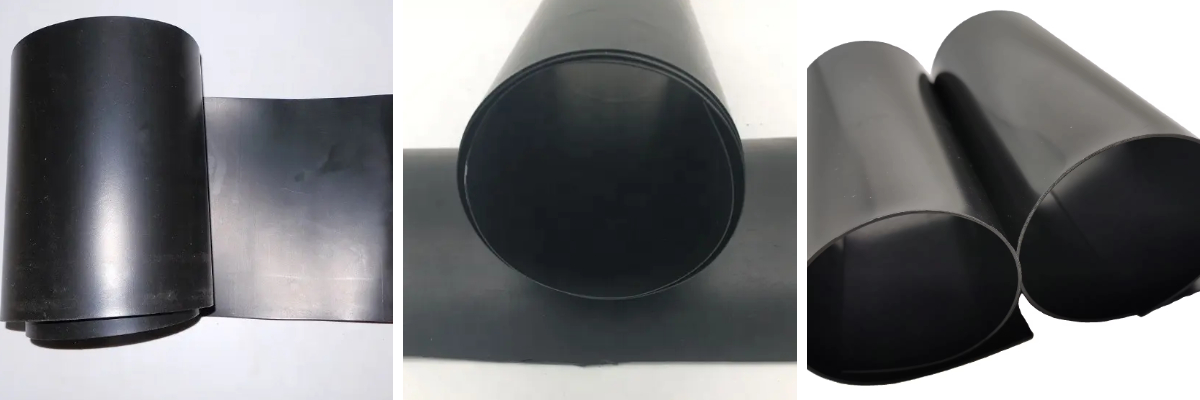

1) Smooth HDPE geomembrane

A smooth HDPE (High-Density Polyethylene) geomembrane is a type of geomembrane with a smooth surface texture.

Smooth HDPE geomembranes are characterized by their flat and smooth surface, which contributes to their impermeability and enhances their performance in preventing the passage of liquids.

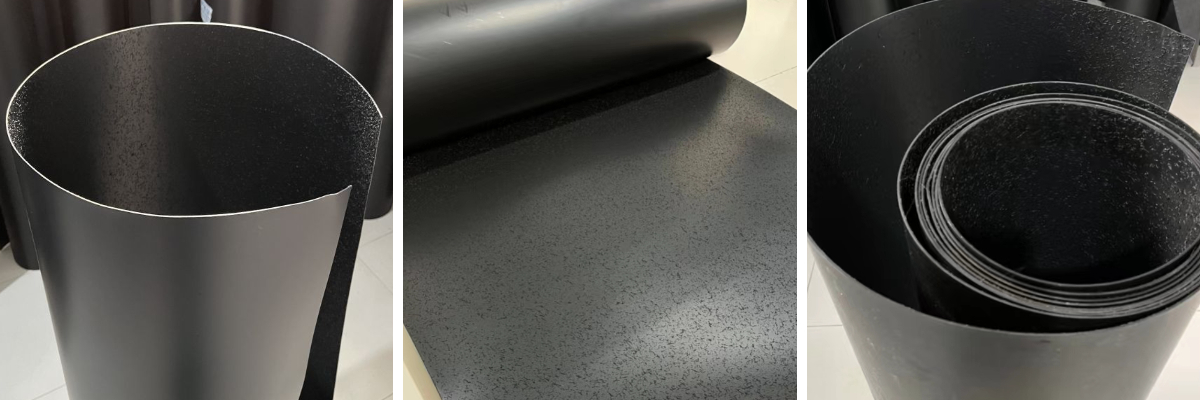

2) Single-textured HDPE geomembrane

A single-rough surface geomembrane has one side with a relatively rough texture, distinguishing it from traditional smooth geomembranes. This rough surface may enhance adhesion with other materials and provide additional friction.

One of the primary functions of a single-rough surface geomembrane is to offer an anti-slip surface, improving stability when walking or placing other materials on it. This is crucial for projects that require enhanced stability. By increasing surface roughness, the geomembrane helps prevent soil erosion, protecting the surface cover from weathering and erosion effects.

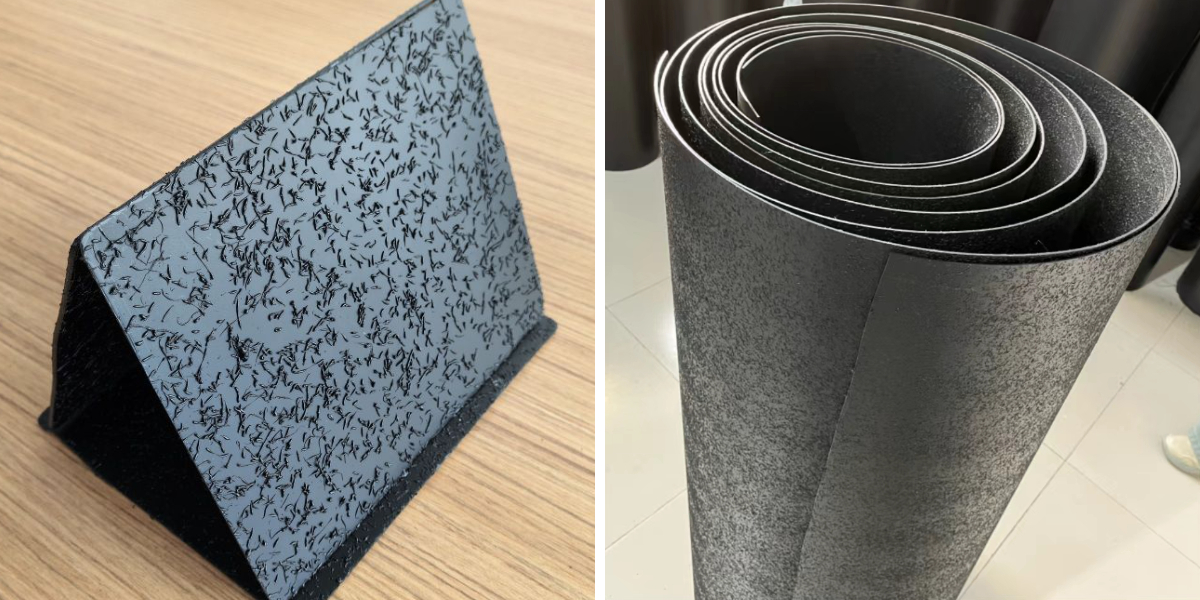

3) Double-textured HDPE geomembrane

Double-textured HDPE geomembrane is high-density polyethylene (HDPE) geomembrane with rough textures on both sides, providing improved adhesion and slip resistance.

The double-textured design aims to increase the adhesion between the geomembrane and other materials, thereby enhancing stability in engineering projects. It is often used in projects with slopes, which can increased stability, adhesion, and slip resistance of the project, while mitigating soil erosion issues and enhancing overall engineering durability.

Application Scenarios

1. Environmental Protection and Sanitation:

Landfills for household waste, sewage treatment plants, power plant regulation ponds, disposal of industrial, medical, and hazardous solid waste, etc.

2. Mining:

Leachate ponds, heap leaching ponds, ash disposal sites, dissolution ponds, settling ponds, evaporation ponds, storage yards, and seepage prevention for tailings ponds.

3. Petroleum and Petrochemical:

Chemical plants, oil refineries, gas stations, impermeable linings for oil storage tanks, internal linings for chemical reaction tanks, and settling ponds.

4. Water Conservancy Projects:

Impermeable linings for rivers, lakes, reservoir embankments, leak plugging and reinforcement, seepage prevention for water channels, slope protection, etc.

5. Agriculture:

Impermeable linings for reservoirs, drinking water ponds, water storage ponds, and irrigation systems.

6. Aquaculture:

Linings for intensive and industrialized breeding ponds, fish ponds, and shrimp ponds.

7. Municipal Engineering:

Impermeable linings for subways, underground constructions, green roofs, rooftop gardens, sewage pipe leak prevention, etc.

8. Landscaping:

Artificial lakes, waterways, reservoirs, and golf courses.

9. Transportation Facilities:

High-speed railways and other transportation infrastructure.

Why choose Haoyang Geomembrane?

1. Imported Raw Materials

High-quality raw materials sourced from **Saudi Arabia** ensure superior product performance and consistency from the source.

2. World-Leading 10m Blown Film Production Line

Equipped with advanced five-layer co-extrusion technology, capable of producing both smooth and textured geomembranes with a maximum width of 10 meters.

3. Direct-from-Factory Production

As a manufacturer, we guarantee premium quality while offering the most competitive prices by eliminating middlemen.

4. Fast Delivery

High daily output of 70 tons ensures timely delivery to meet urgent project timelines.

5. One-Stop Solution

Beyond manufacturing and sales, we provide **professional project construction teams** to deliver end-to-end solutions for seamless project execution.