Geomembrane Liner For Landfill Use

1.100% Virgin HDPE – Stable quality and long-term performance

2.Ultra-Low Permeability – Prevents landfill leachate leakage

3.Excellent Chemical Resistance – Withstands acids, alkalis, and waste liquids

4.High Puncture Strength – Reliable under heavy landfill loads

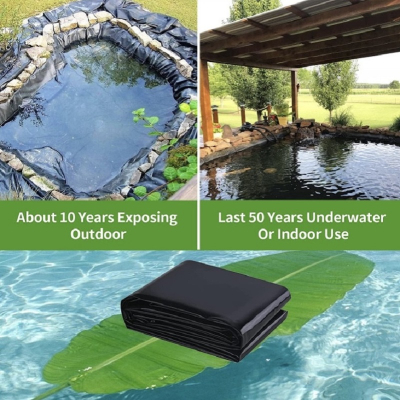

5.UV & Aging Resistant – Suitable for long-term outdoor exposure

6.ASTM & GRI GM13 Certified – Meets international landfill standards

Modern landfill engineering places strict demands on environmental protection, structural stability, and long-term durability. As a critical barrier system, geomembrane liners for landfill use play a vital role in preventing leachate leakage, protecting soil and groundwater, and ensuring regulatory compliance throughout the landfill’s service life.

What Is a Geomembrane Liner for Landfills?

A geomembrane liner is a high-performance synthetic membrane, most commonly manufactured from HDPE (High-Density Polyethylene), designed to provide an impermeable barrier in landfill containment systems. It is widely used in municipal solid waste landfills, hazardous waste landfills, industrial waste disposal sites, and landfill caps.

Due to its excellent chemical resistance, mechanical strength, and long service life, HDPE geomembrane has become the preferred liner material for landfill applications worldwide.

Key Functions in Landfill Systems

In a landfill structure, geomembrane liners are typically used as:

Primary liners to prevent leachate from migrating into the subsoil

Secondary liners as backup containment layers

Capping liners to control gas emissions and water infiltration after landfill closure

By working together with geotextiles, drainage layers, and leak detection systems, geomembrane liners form a complete and reliable landfill containment solution.

Product Advantages

1. Excellent Impermeability

Geomembrane liners feature ultra-low permeability, effectively blocking landfill leachate and contaminated liquids from penetrating into soil and groundwater.

2. Superior Chemical Resistance

HDPE geomembranes resist a wide range of chemicals, including acids, alkalis, salts, and organic compounds commonly found in landfill leachate.

3. High Mechanical Strength

Designed to withstand heavy waste loads and differential settlement, landfill geomembranes offer high tensile strength, tear resistance, and puncture resistance.

4. UV and Aging Resistance

With added carbon black and antioxidants, geomembrane liners maintain stable performance under long-term UV exposure and harsh outdoor conditions.

5. Long Service Life

Properly manufactured and installed geomembrane liners can achieve a service life of several decades, significantly reducing maintenance and replacement costs.

6. Flexible Installation

The material adapts well to uneven subgrades, slopes, and complex landfill geometries, ensuring secure and continuous liner coverage.

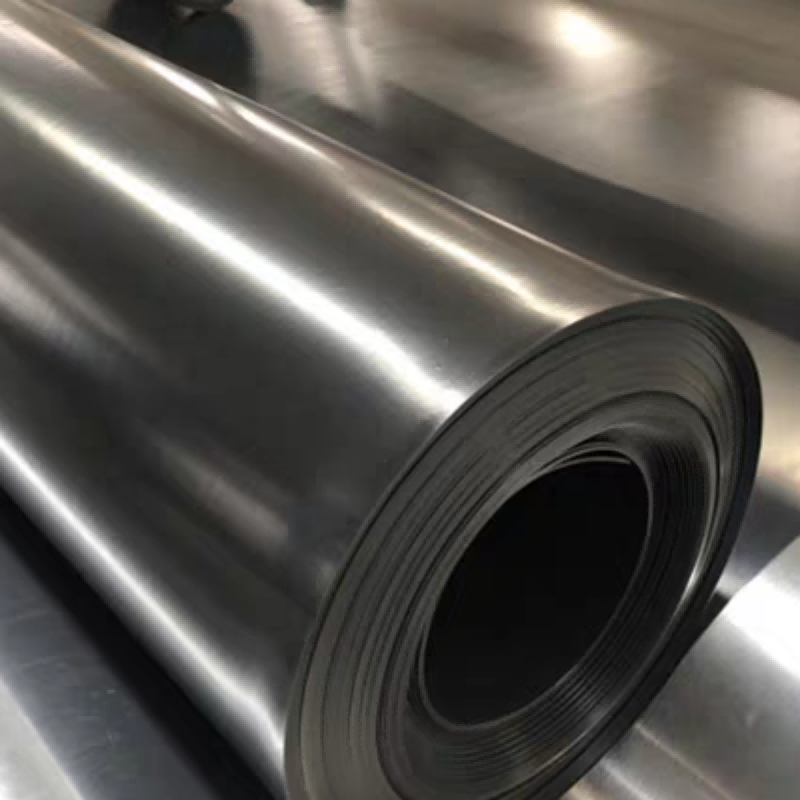

Smooth vs. Textured Geomembrane for Landfills

Landfill projects often require both smooth and textured geomembranes:

Smooth geomembranes are commonly used on flat areas and bottom liners where maximum impermeability is required.

Textured geomembranes provide enhanced friction and interface stability, making them ideal for slopes, sidewalls, and landfill caps.

Textured surfaces help reduce slippage between layers, improving overall slope safety in landfill engineering.

Manufacturing Quality Matters

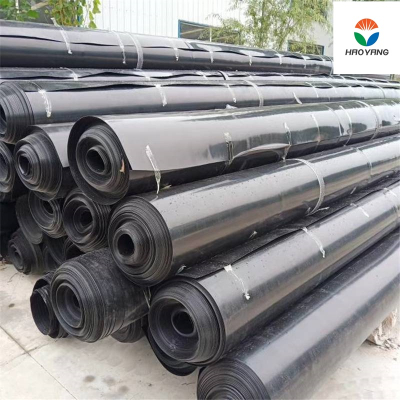

High-quality landfill geomembrane liners are produced using 100% virgin raw materials, ensuring consistent thickness, uniform density, and superior mechanical properties. Advanced extrusion and calendering processes guarantee smooth surfaces, precise thickness control, and reliable performance.

At Haoyang Environmental, geomembrane liners are manufactured under strict quality management systems and tested for thickness, tensile strength, elongation, puncture resistance, carbon black content, and oxidative induction time.

Compliance with International Standards

Reliable geomembrane liners for landfill use should meet internationally recognized standards, such as:

ASTM standards

GRI GM13 specifications

Compliance with these standards ensures the liner meets engineering and environmental protection requirements for landfill projects around the world.

Typical Applications

Geomembrane liners are widely used in:

Municipal solid waste landfills

Hazardous waste landfills

Industrial waste disposal sites

Landfill capping and closure systems

Leachate ponds and treatment facilities

Their adaptability makes them suitable for both new landfill construction and rehabilitation projects.

Why Choose a Reliable Manufacturer?

Choosing the right geomembrane liner supplier is just as important as selecting the right material. A reliable manufacturer offers:

Source factory production with stable supply capacity

Customized thickness, width, and surface texture

Consistent quality using virgin materials

Experience in large-scale and government landfill projects

These factors help ensure project safety, cost efficiency, and long-term environmental protection.

FAQ

Q1: What material is best for landfill geomembrane liners?

HDPE (High-Density Polyethylene) is the most widely used material for landfill liners due to its excellent chemical resistance, low permeability, high mechanical strength, and long service life.

Q2: What thickness is commonly used for landfill applications?

Common thicknesses range from 1.0 mm to 2.0 mm, depending on landfill type, waste characteristics, load conditions, and local regulatory requirements.

Q3: Should I choose smooth or textured geomembrane for a landfill project?

Smooth geomembranes are typically used for flat areas and bottom liners, while textured geomembranes are recommended for slopes and sidewalls to improve friction and slope stability.

Q4: Can geomembrane liners resist landfill leachate?

Yes. HDPE geomembrane liners offer excellent resistance to acids, alkalis, salts, and organic compounds commonly found in landfill leachate.

Q5: How long is the service life of a landfill geomembrane liner?

When manufactured from 100% virgin materials and properly installed, HDPE geomembrane liners can achieve a service life of several decades.

Q6: Are geomembrane liners UV resistant?

Yes. Landfill geomembranes contain carbon black and antioxidants that provide strong UV and aging resistance for long-term outdoor exposure.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

A geomembrane liner for landfill use is a critical component in modern waste management infrastructure. With its outstanding impermeability, chemical resistance, mechanical strength, and durability, HDPE geomembrane provides reliable containment performance throughout the landfill’s lifecycle.

Selecting high-quality materials and an experienced manufacturer ensures compliance with environmental standards while protecting natural resources for future generations.