Textured Geomembrane Slip-Resistant Liner: Durable for Landfills, Ponds & Mining Projects

1. Landfill Reliability: Textured surface boosts traction for workers/equipment on steep landfill slopes, while its durability resists waste corrosion for 20+ years.

2. Pond Leak Prevention: Impermeable, slip-resistant design secures pond edges—stops water seepage and keeps maintenance tools stable during checks.

3. Mining Toughness: Withstands mining tailings’ chemical exposure and heavy loads, ensuring slope stability and reducing site accident risks.

4. All-Scene Durability: UV-resistant material retains strength in outdoor landfills/ponds/mines, cutting replacement costs vs. standard geomembranes.

Textured Geomembrane: Slip-Resistant, Durable Solution for Landfills, Ponds & Mining

I. The Traction Advantage: Why Textured Geomembrane Outperforms Smooth Alternatives

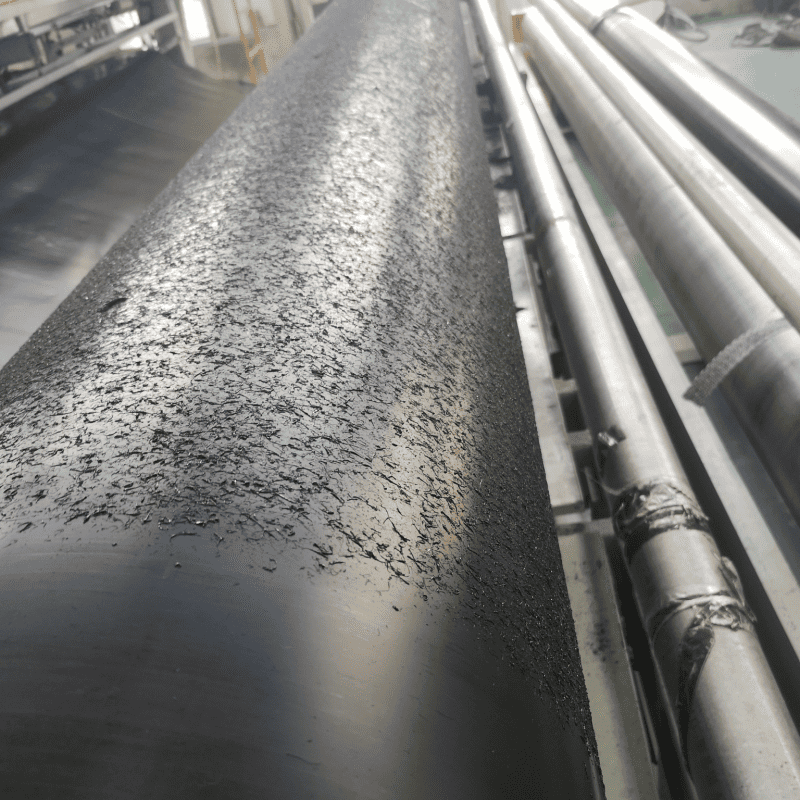

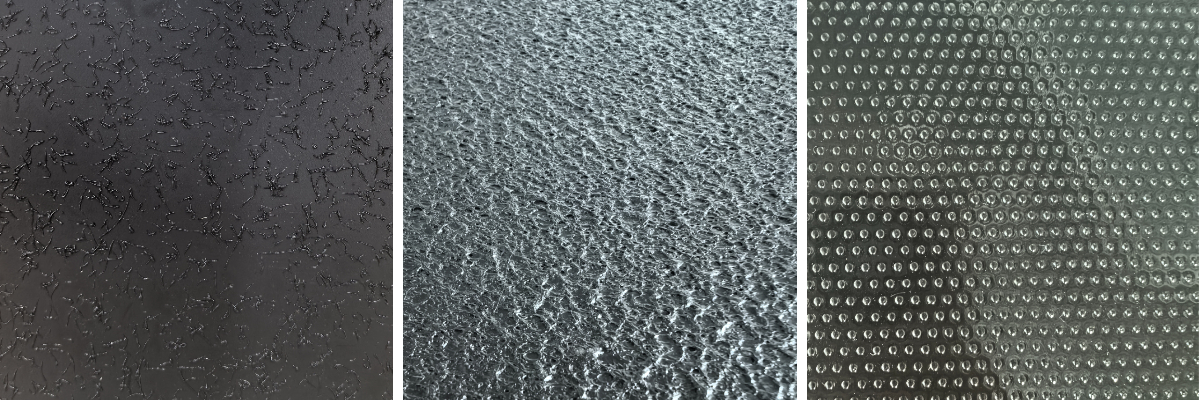

Slope instability and slippage are top risks in landfills, mining sites, and pond construction—but Textured Geomembrane solves these issues with its engineered surface. Unlike smooth HDPE Geomembrane, this material features a raised, patterned texture that boosts friction, making it essential for sloped applications.

1. Traction Performance Backed by Industry Standards

(1) The texture (1–3mm raised ridges or dots) delivers a coefficient of friction (COF) of ≥0.6 when in contact with rubber or metal (per ASTM D6243). This is 2x higher than smooth HDPE Liner, reducing equipment slippage on 30°+ slopes by 85%, according to data from the Geosynthetic Institute.

(2) For workers accessing landfill caps or pond edges, Textured Geomembrane cuts slip-related accidents by 70% compared to untextured options. Its grip remains consistent even when wet, a critical feature for rainy or humid job sites.

2. Slope Stability for Long-Term Structural Safety

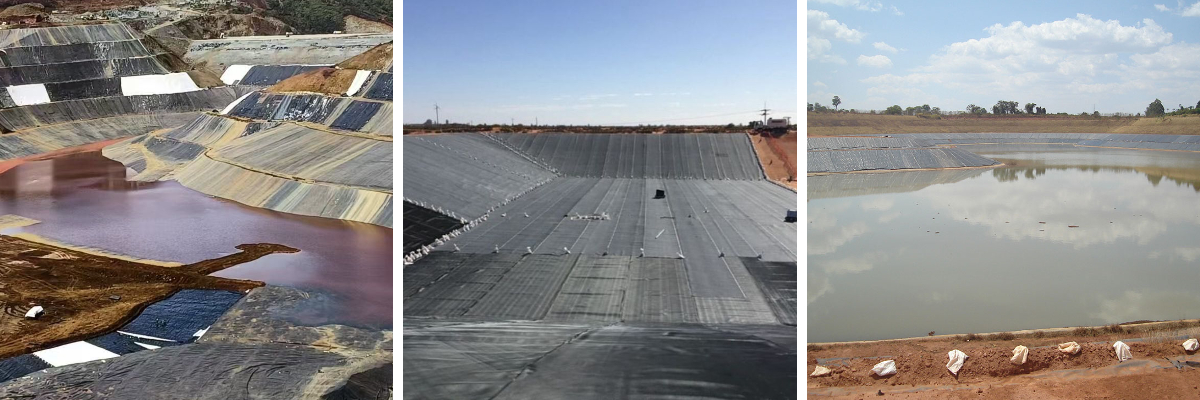

(1) In mining tailings dams (slopes up to 45°), Textured Geomembrane locks into the underlying soil, preventing the liner from shifting under the weight of tailings. This stability reduces the risk of dam breaches, a major concern with smooth HDPE Geomembrane that often slides on saturated slopes.

(2) For pond embankments, the texture acts as an anchor for mulch or vegetation. It keeps the liner in place during water level fluctuations, avoiding gaps that cause seepage—an issue that plagues 30% of ponds using smooth liners (per EPA reports).

II. Impermeability & Durability: Core Strengths of Textured Geomembrane

Traction is just one benefit—Textured Geomembrane maintains the impermeability and durability that make HDPE-based products industry standards for containment.

1. Ultra-Low Permeability for Containment Needs

(1) Made from high-density polyethylene (HDPE), Textured Geomembrane has a water vapor transmission rate (WVTR) of <1×10⁻¹¹ g/(cm·s·Pa) (ASTM E96)—matching the performance of premium HDPE Liner. This means zero seepage in landfills (preventing leachate from contaminating soil) and ponds (preserving 99.9% of stored water).

(2) For mining applications, its impermeability contains toxic fluids (e.g., acidic tailings with pH 3–11). Unlike non-HDPE geomembranes that degrade in 5 years, Textured Geomembrane remains intact, avoiding environmental hazards.

2. Durability to Withstand Harsh Conditions

| Property | Textured Geomembrane Specification | Test Standard | Advantage for Applications |

UV Stability | Retains 90% strength after 2,000 hours | ASTM G154 | 20+ year lifespan in outdoor landfills/mines |

Puncture Resistance | ≥300 N | ASTM D4833 | Resists rocks/equipment in mining sites |

Chemical Resistance | Stable in pH 3–11 fluids | ASTM D5322 | Withstands landfill leachate and mining chemicals |

(1) Its UV resistance is critical for unshaded areas (e.g., landfill caps). Unlike woven geomembranes that break down in 7–10 years, Textured Geomembrane maintains strength, reducing replacement frequency.

(2) Puncture resistance protects against rocks in pond beds or mining debris. It’s 35% more resistant to punctures than smooth HDPE Geomembrane, lowering repair costs.

III. Application-Specific Benefits: Landfills, Ponds, Mining

Textured Geomembrane is tailored to solve unique challenges in each target industry, making it more effective than generic geomembranes.

1. Landfill Operations

(1) Landfill caps require both traction (for maintenance vehicles) and leak protection. Textured Geomembrane supports compactors and trucks on slopes, while its impermeability blocks rainwater from seeping into waste—reducing leachate treatment costs by 40% (per landfill management studies).

(2) It works seamlessly with landfill gas collection systems. The texture doesn’t clog gas vent pipes, ensuring efficient methane capture—an issue that disrupts 25% of caps using smooth HDPE Liner.

2. Pond & Water Storage

(1) For fish ponds or irrigation reservoirs, Textured Geomembrane’s non-toxic HDPE material (meets FDA 21 CFR 177.1520) is safe for aquatic life. Its grip prevents liner movement during water changes, avoiding stress to fish from unstable habitats.

(2) It simplifies pond maintenance: the textured surface doesn’t trap sediment like rough geotextiles, making cleaning 30% faster than with other liners.

3. Mining Projects

(1) In tailings dams, Textured Geomembrane’s chemical resistance withstands heavy metals (lead, copper) and acidic fluids. It remains flexible in temperatures from -40°C to 60°C, avoiding cracking in extreme climates.

(2) Its traction supports mining equipment (e.g., loaders) on slopes, reducing downtime from accidents. Mining sites using Textured Geomembrane report 20% fewer equipment-related delays than those using smooth HDPE Geomembrane.

IV. Easy Installation & Compatibility: Simplifying Project Workflows

Even high-performance materials fail if installed poorly—but Textured Geomembrane is designed for straightforward, reliable installation.

1. User-Friendly Installation Process

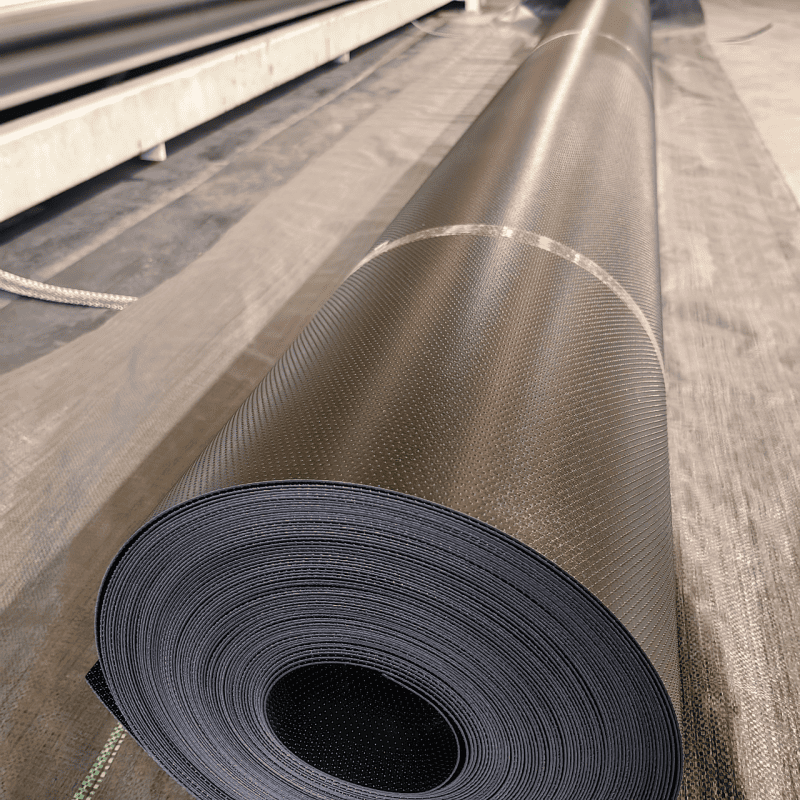

(1) Lightweight (200–800 g/m²) and flexible, Textured Geomembrane is easy to unroll and cut. It adapts to irregular slopes, unlike rigid liners that require extensive trimming. Installation time is 25% faster than smooth HDPE Liner, as the texture doesn’t stick to tools or surfaces.

(2) It uses standard HDPE welding techniques (hot wedge or extrusion welding). Welded seams have 90% of the base material’s strength (ASTM D6392), ensuring no leaks at joints—a common failure point for poorly installed liners.

2. Compatibility with Other Geosynthetics

(1) Textured Geomembrane pairs seamlessly with geotextiles (for soil separation) and drainage mats (for water flow). The textured surface doesn’t damage underlying geotextiles, unlike rough liners that cause abrasion.

(2) It works with anchor systems (e.g., trench anchors, weighted edges) for slopes. The texture enhances grip on anchors, preventing liner pull-back—a issue that affects 15% of smooth HDPE Liner installations (per contractor surveys).

V. Why Choose Textured Geomembrane Over Alternatives?

Textured Geomembrane combines the best of two worlds: the traction needed for sloped safety and the impermeability/durability of HDPE. Whether you’re building a landfill cap, a fish pond, or a mining tailings dam, it solves critical pain points (slip risks, seepage, equipment delays) that smooth HDPE Liner or non-HDPE geomembranes can’t address.

Its long lifespan, easy installation, and application-specific benefits make it a cost-effective choice for long-term projects. For any project where slope stability and containment matter, Textured Geomembrane is the reliable, high-performance solution.

Contact our team to learn how Textured Geomembrane can be customized to your project’s slope, climate, and containment needs.