Anti-seepage HDPE Geomembranes for Reservoir

1. Watertight Seal: Stops leaks, keeping reservoir levels stable in porous soil.

2. 20+ Year Durability: Withstands water pressure, sediment, and weather.

3. Resists Elements: UV and chemical-proof for mineral-rich water.

4. Weldable Seams: Forms a unified barrier, no weak spots in large basins.

5. Safe for Water: Non-toxic, ideal for drinking/irrigation storage.

6. Saves Costs: Cuts refill expenses by 60%+ vs. unlined reservoirs.

Anti-seepage HDPE Geomembranes for Reservoir - Impermeable, durable & safe. Ideal for water storage, preventing leaks and ensuring stable levels in reservoirs..

Anti-seepage HDPE Geomembranes for Reservoir: Safeguarding Water Storage

Water is a precious resource, and reservoirs play a crucial role in storing it for various purposes such as irrigation, drinking water supply, and industrial use. However, water loss due to seepage in reservoirs has always been a major concern. The Anti-seepage HDPE Geomembranes for Reservoir emerge as a reliable solution to this problem. These specialized geomembranes are designed to create a highly effective barrier that minimizes water seepage, ensuring the efficient and sustainable operation of reservoirs.

1. Product Construction

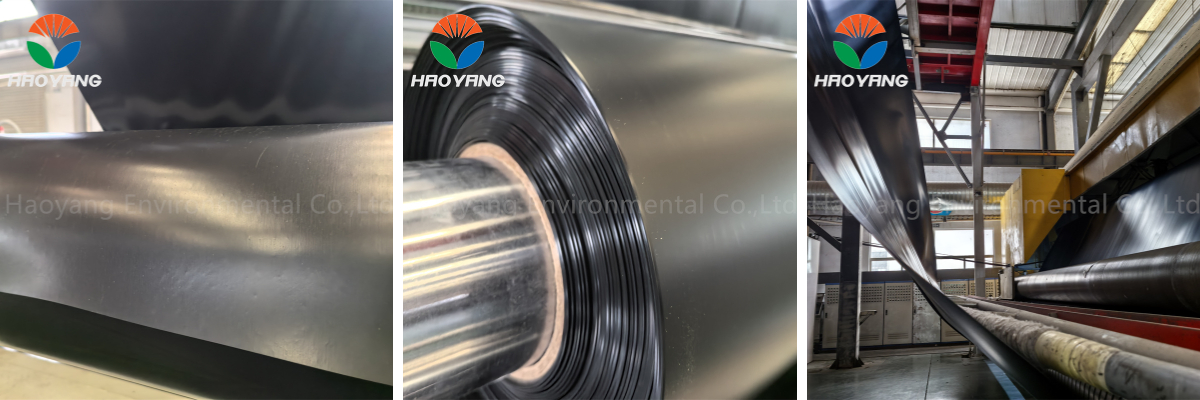

The Anti-seepage HDPE Geomembranes for Reservoir are primarily made from high - density polyethylene (HDPE). This material is chosen for its exceptional properties that make it suitable for the demanding environment of reservoirs. The manufacturing process involves extruding HDPE into thin sheets of varying thicknesses, typically ranging from 0.5mm to 2.0mm. The sheets are then reinforced with a special additive package that enhances their resistance to UV radiation, chemicals, and mechanical stress. This construction ensures that the geomembranes can withstand the harsh conditions present in reservoirs, including constant contact with water, exposure to sunlight, and the weight of the water and sediment.

2. Technical Specifications

Property | Specification | Relevance to Reservoir Scenario |

Material | High - density polyethylene (HDPE) | Offers excellent impermeability and chemical resistance, essential for preventing water seepage and withstanding water - related chemicals. |

Thickness | 0.5mm - 2.0mm | Thicker membranes provide greater strength and durability, suitable for reservoirs with higher water pressure and larger storage capacities. |

Impermeability | <1×10⁻¹¹ cm/s | Ensures minimal water seepage, which is critical for maintaining reservoir water levels and reducing water loss. |

Tensile Strength | ≥20 MPa | Allows the geomembrane to withstand the tensile forces exerted by the water and soil, preventing tearing and rupture. |

Elongation at Break | ≥400% | Provides flexibility to adapt to minor movements of the reservoir foundation without cracking. |

UV Resistance | ≥5000 hours of accelerated UV testing | Enables long - term use in outdoor reservoirs without degradation from sunlight exposure. |

Chemical Resistance | Resistant to most acids, alkalis, and salts | Withstands the chemical composition of reservoir water, which may contain various minerals and impurities. |

3. Adaptability to Reservoir Environment

(1) Seepage Prevention

The key function of these geomembranes in reservoirs is to prevent water seepage. The low permeability of HDPE, with a seepage rate of less than 1×10⁻¹¹ cm/s, ensures that only a negligible amount of water is lost through the membrane. This is especially important for reservoirs built in areas with porous soil, where seepage can be a significant problem. By reducing water loss, the geomembranes help to maintain stable water levels in the reservoir, ensuring a reliable water supply for irrigation, drinking, and other purposes.

(2) Resistance to Water Pressure

Reservoirs store large volumes of water, which exerts significant pressure on the bottom and sides of the reservoir. The Anti-seepage HDPE Geomembranes have high tensile strength (≥20 MPa) and good elongation at break (≥400%), allowing them to withstand this pressure without being damaged. They can adapt to the slight deformation of the reservoir structure caused by water pressure, ensuring the integrity of the anti-seepage barrier.

(3) UV and Weather Resistance

Reservoirs are usually located outdoors, exposed to sunlight, rain, snow, and temperature fluctuations. The UV - resistant additive in the HDPE geomembranes ensures that they do not degrade easily under prolonged sunlight exposure. They can also withstand extreme temperatures, from -40°C to 60°C, making them suitable for use in various climatic conditions. This resistance to weathering ensures a long service life for the geomembranes, reducing the need for frequent replacement.

(4) Compatibility with Reservoir Ecosystem

The HDPE material used in these geomembranes is inert and non - toxic, which means it does not release harmful substances into the water. This is crucial for reservoirs that are used for drinking water supply or to support aquatic life. The geomembranes do not affect the water quality, ensuring that the water remains safe for human consumption and for the survival of fish and other aquatic organisms. In addition, they do not interfere with the natural processes of the reservoir ecosystem, such as the circulation of nutrients.

4. Installation and Maintenance

(1) Installation Process

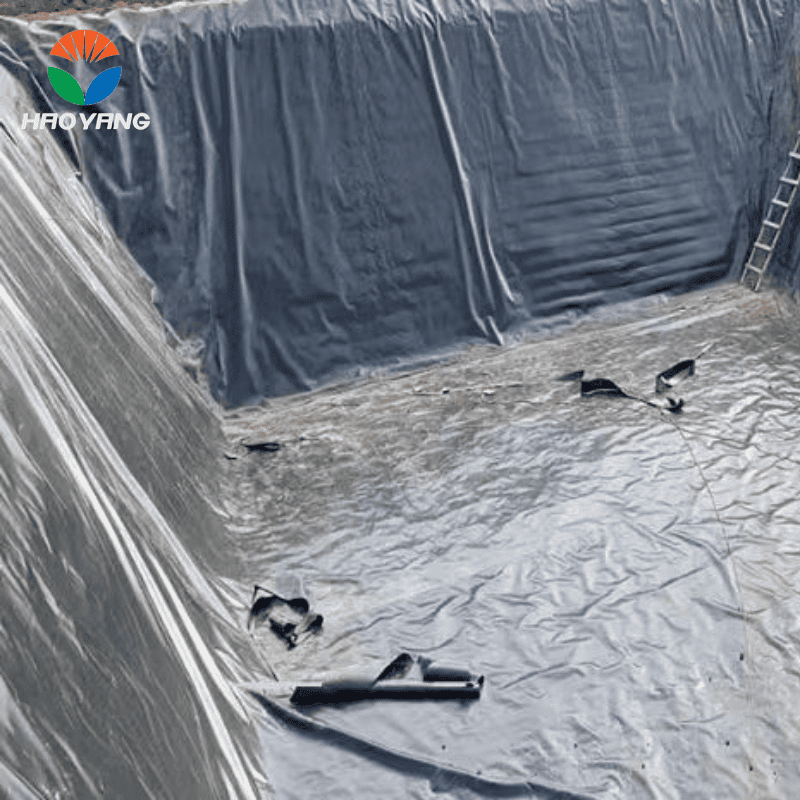

Site Preparation: Before installing the geomembranes, the reservoir bed and slopes must be properly prepared. This involves removing any sharp objects, rocks, and debris that could puncture the geomembrane. The surface should be leveled and compacted to provide a smooth and stable base.

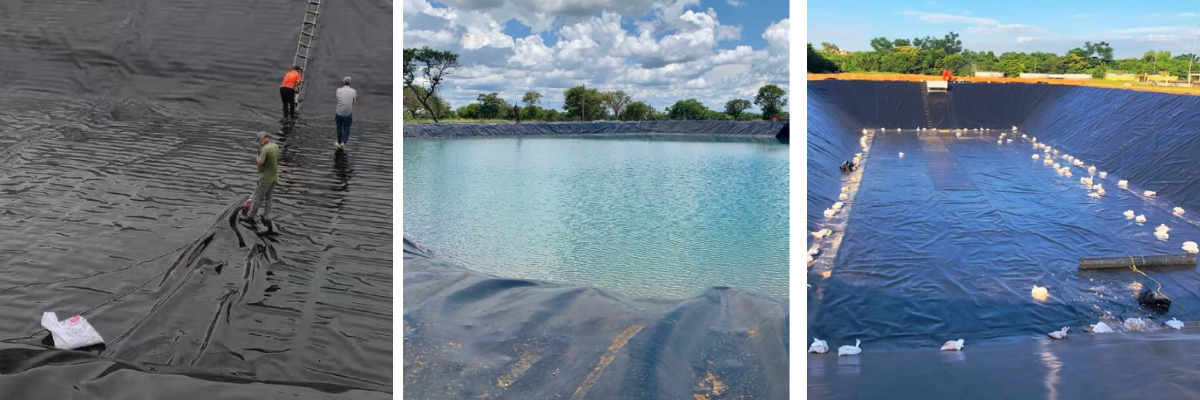

Unfolding and Laying: The geomembrane rolls are transported to the reservoir site and unfolded carefully. They are laid out according to the design, ensuring that there are no wrinkles or folds. The sheets are overlapped by a certain width, typically 10 - 15 cm, to ensure a proper seal.

Welding: The overlapping edges of the geomembrane sheets are welded together using specialized welding equipment. There are two main types of welding methods: hot wedge welding and extrusion welding. Hot wedge welding is suitable for most applications, while extrusion welding is used for more critical areas or where a stronger bond is required. The welding process ensures that the seams are as strong and impermeable as the rest of the geomembrane.

Inspection: After welding, the entire geomembrane installation is inspected. This includes checking the welds for leaks using a vacuum tester or air pressure tester. Any defects or leaks found are repaired immediately to ensure the integrity of the barrier.

(2) Maintenance Measures

Regular Inspection: Regular inspections of the geomembranes are essential to detect any signs of damage or wear. Inspections should be carried out at least once a year, and more frequently after extreme weather events or other potential sources of damage. During inspections, look for punctures, tears, cracks, and signs of UV degradation.

Repair of Damage: If any damage is found, it should be repaired promptly. Small punctures or tears can be patched using a compatible HDPE patch and welding equipment. For larger areas of damage, the affected section of the geomembrane may need to be replaced.

Cleaning: Periodically, the surface of the geomembrane may need to be cleaned to remove accumulated sediment, algae, and other debris. This can be done using a soft brush or a high - pressure water jet, taking care not to damage the geomembrane.

Protection from External Factors: Measures should be taken to protect the geomembranes from external damage. This includes avoiding driving heavy machinery over the geomembrane, preventing the growth of tree roots near the geomembrane, and controlling the activities of animals that could puncture the material.

5. Application Cases

(1) Irrigation Reservoirs

In irrigation reservoirs, water loss through seepage can lead to reduced water availability for crops, especially during dry seasons. The installation of Anti-seepage HDPE Geomembranes has been shown to reduce water loss by up to 90% in such reservoirs. This ensures that there is an adequate supply of water for irrigation, improving crop yields and reducing the need for additional water sources. For example, in a large irrigation reservoir in a semi - arid region, the use of these geomembranes has resulted in a significant increase in the area that can be irrigated, supporting the local agricultural economy.

(2) Drinking Water Reservoirs

Drinking water reservoirs require the highest standards of water quality and seepage control. The Anti-seepage HDPE Geomembranes provide an effective barrier that prevents contaminants from entering the water from the surrounding soil. They also minimize water loss, ensuring a reliable supply of drinking water. In a drinking water reservoir serving a city, the installation of these geomembranes has helped to maintain consistent water levels and has reduced the cost of water treatment by preventing the infiltration of pollutants.

(3) Flood Control Reservoirs

Flood control reservoirs need to be able to hold large volumes of water during flood events. The Anti-seepage HDPE Geomembranes ensure that the reservoirs can retain the water without significant seepage, allowing them to function effectively in flood control. They also help to protect the structural integrity of the reservoir, preventing erosion and instability caused by water seepage. In a flood control reservoir in a river basin, the use of these geomembranes has increased the reservoir's storage capacity and improved its ability to mitigate flood risks.

The Anti-seepage HDPE Geomembranes for Reservoir are a vital component in the efficient and sustainable management of reservoirs. Their excellent impermeability, durability, and compatibility with the reservoir environment make them an ideal choice for preventing water seepage and ensuring the long - term performance of reservoirs. Whether it is for irrigation, drinking water supply, or flood control, these geomembranes provide a cost - effective and reliable solution.

If you are planning a reservoir project and need a high - quality anti - seepage solution, please contact us. Our team of experts can provide you with professional advice and customized solutions to meet your specific needs.