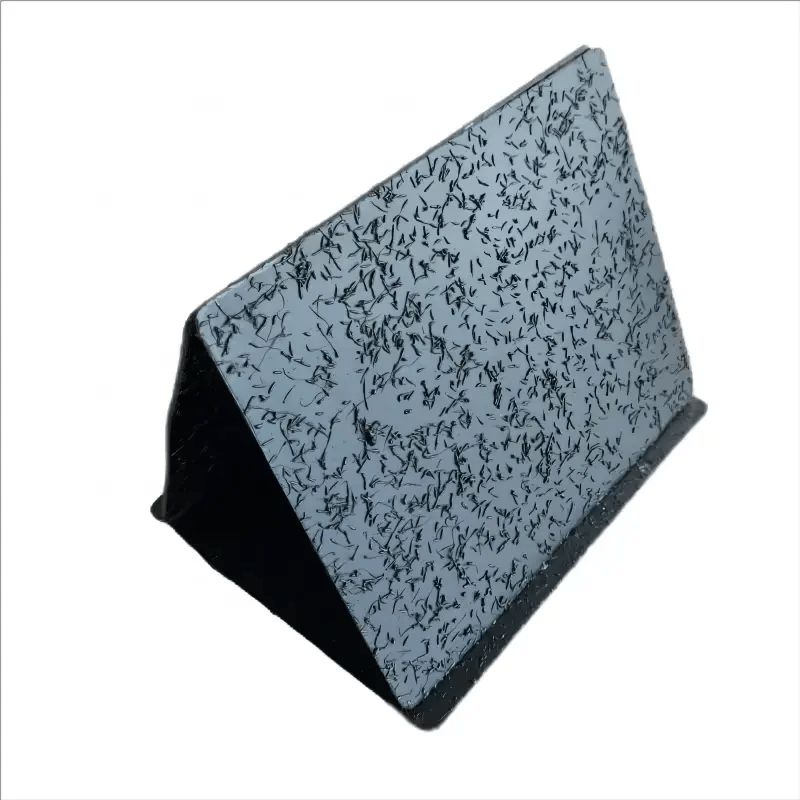

0.75mm High-Quality Anti-Seepage HDPE Geomembrane

1. Strong water resistance: The high-density polyethylene (HDPE) material has a dense structure, and a thickness of 0.75mm can effectively prevent water, liquids, and harmful media from penetrating.

2. High durability: Resistant to ultraviolet rays, acid and alkali corrosion, and with high tensile strength, it can withstand the impact of construction and external environmental forces.

3. Easy construction: The material is flexible, and can be cut and spliced according to the site. The welding process is mature, the joints are firm and have strong sealing performance.

4. Environmentally friendly and safe: Using high-quality HDPE raw materials, it does not release toxic or harmful substances, will not pollute the soil and water sources.

5. Economical and practical: Although the initial cost is slightly higher, it has strong durability, low maintenance requirements, and combines performance and economy.

Introduction to Geomembrane

The core raw material is high-density polyethylene (HDPE) resin (accounting for over 95%), with a small amount of antioxidants, anti-ultraviolet agents and other additives added. It is processed through extrusion blow molding or calendering technology to produce a 0.75mm thick flexible anti-seepage membrane. The product is mainly characterized by its high-efficiency water-proofing performance. It can prevent the penetration of water and chemical liquids, is resistant to acid and alkali, and is anti-aging. It is suitable for scenarios such as landfill sites and reservoirs. The construction is easy to assemble and connect, and it combines environmental friendliness with durability.

Technical Specifications

| Technical Indicator | Unit | Typical Value | Description |

| Thickness | mm | 0.75±0.05 | Thickness uniformity directly affects anti-seepage performance |

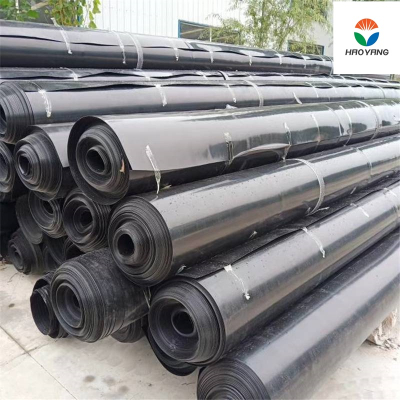

| Width | m | 2-8 | Conventional width, customizable to reduce seams |

| Tensile Strength (MD/TD) | MPa | ≥23 / ≥21 | Measures the material's resistance to tensile fracture |

| Elongation at Break (MD/TD) | % | ≥700 / ≥650 | Reflects material flexibility to adapt to site deformation |

| Right-Angle Tear Strength (MD/TD) | kN/m | ≥8.0 / ≥7.5 | Resists tearing caused by construction or external forces |

| Hydrostatic Pressure Resistance (24h) | MPa | ≥1.6 | No leakage; core anti-seepage performance indicator |

0.75mm HDPE Geomembrane Installation Steps

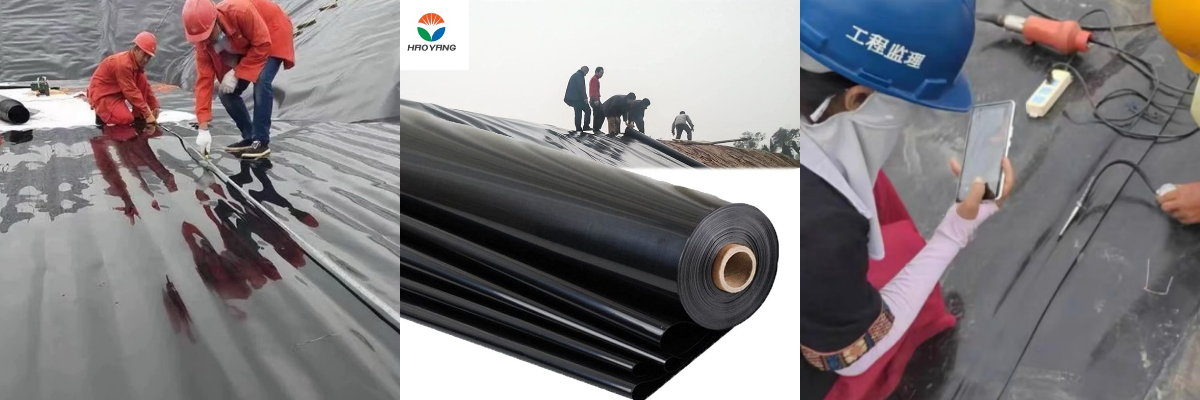

1. Site Preprocessing: Remove debris such as gravel and weeds from the construction area, level the ground and compact it. Fill low-lying areas with plain soil to ensure there are no sharp objects on the base, and prevent the membrane from being punctured.

2. Membrane Laying: Cut the membrane according to the site dimensions, lay it from one end to the other, leaving a 10-15cm overlap between the strips to avoid excessive tension on the membrane and to accommodate slight deformation of the site.

3. Welding and Splicing: Use a hot air gun or double-track hot melt welding machine to weld the overlap edges. Control the temperature (180-220℃) and speed to ensure the welds are smooth and free of bubbles. Perform pressure testing on each weld section.

4. Edge Fixation: Connect the membrane edges to the surrounding concrete caps or anchoring grooves, and fix them with expansion bolts to prevent the membrane from shifting. Add gaskets at the anchoring points to avoid damaging the membrane.

5. Inspection and Acceptance: Conduct a comprehensive inspection of the membrane surface for any damages and check if the welds are leaking. Repair any defects promptly and confirm that the overall system meets the anti-seepage requirements before proceeding to the next construction stage.

0.75mm HDPE Geomembrane Application Scenarios

1. Leachate Barrier for Landfill: Installed at the bottom and slopes of the landfill to prevent leachate from seeping into the soil and groundwater, thus avoiding pollution of the surrounding ecosystem. Its acid and alkali resistance and anti-aging properties enable it to withstand the corrosive substances produced by garbage decomposition for a long time, ensuring the compliant operation of the landfill in terms of environmental protection.

2. Leachate Barrier for Water Conservancy Projects: Suitable for scenarios such as reservoirs, water storage tanks, and artificial lakes, installed on the dam body or bottom of the tank to reduce water leakage loss. The 0.75mm thickness strikes a balance between leachate barrier effect and construction flexibility, allowing it to conform to complex terrain and assist in water conservation and the safety and stability of water conservancy facilities.

3. Chemical / Wastewater Treatment: Used for the leachate barrier layer in chemical storage areas and the lining of wastewater treatment ponds, isolating chemical solutions from wastewater to prevent the leakage of harmful substances. The material is environmentally friendly with no emissions and has strong resistance to chemical corrosion, meeting the requirements of industrial environmental protection and safe production.

4. Tailings Reservoir Leachate Barrier: Applied to the bottom of the tailings reservoir area to prevent the heavy metal ions and harmful liquids in the tailings slurry from seeping into the ground, protecting the surrounding soil and water resources. Its high tensile strength can adapt to the deformation caused by tailings accumulation, enhancing the safety level of the tailings reservoir.

5. Agricultural Irrigation Facilities: Used for the inner lining of irrigation reservoirs and water conveyance channels to reduce water leakage and increase the utilization rate of irrigation water. The material has strong weather resistance and can withstand outdoor exposure to sunlight and rain, meeting the demand for low-cost and high-durability leachate barrier materials in agricultural production.

Specifications and Prices

| Thickness(mm) | Width(m) | Roll Length(m) | General Performance Indicators | Price Range |

| 0.3 - 0.5 | 2-10 | Customizable | Permeability coefficient ≤ 10⁻¹³ cm/s, tensile strength ≥ 25MPa, carbon black content ≥ 2% | US$0.94 - 1.14 / ㎡ |

| 0.75 | 2-10 | Customizable | Permeability coefficient ≤ 10⁻¹³ cm/s, tensile strength ≥ 25MPa, carbon black content ≥ 2% | US$1.27 - 1.83 / ㎡ |

| 1 | 2-10 | Customizable | Density ≥ 0.94g/cm³, tensile yield strength ≥ 15N/mm, tear resistance ≥ 125N, puncture resistance ≥ 320N | US$0.89 - 0.99 / ㎡ |

| 1.5 | 2-10 | Customizable | Density ≥ 0.94g/cm³, tensile yield strength ≥ 22N/mm, tear resistance ≥ 190N, puncture resistance ≥ 480N | US$0.13 - 0.39 / ㎡ |

| 2 | 2-10 | Customizable | Density ≥ 0.94g/cm³, tensile yield strength ≥ 29N/mm, tear resistance ≥ 250N, puncture resistance ≥ 640N | About US$2.78 / ㎡ |

The advantages of Haoyang Environment's production of 0.75mm HDPE Geomembrane

1. Advanced production technology: Haoyang Environment adopts international leading fully automatic production equipment and uses a three-layer co-extrusion technology to manufacture 0.75mm HDPE Geomembrane. This process ensures uniform product thickness and a dense structure, effectively enhancing the anti-seepage performance. Its water vapor permeability coefficient is as low as K <= 1.0 * 10-13 cm/(cm2·s·Pa), far exceeding that of ordinary products from other industries.

2. Quality raw material control: High-quality polyethylene virgin resin is selected, with the main component being high-density polyethylene, and carbon black, anti-aging agents, and other auxiliary materials are scientifically proportioned. Among them, the content of high-density polyethylene is approximately 97.5%, ensuring that the product has excellent tensile strength (≥28MPa), tear resistance, and puncture resistance, and can adapt to complex construction and usage environments.

3. Comprehensive testing guarantee: Haoyang has a CNAS-recognized laboratory equipped with advanced and precise testing instruments. According to multiple international standards (GRI), American standards (ASTM), Chinese urban construction standards (CJ/T234—2006), and national standards (GB/T17643—2011), each batch of products undergoes strict testing to ensure the stable and reliable quality of 0.75mm HDPE Geomembrane, laying a solid foundation for the long-term safe operation of the project.