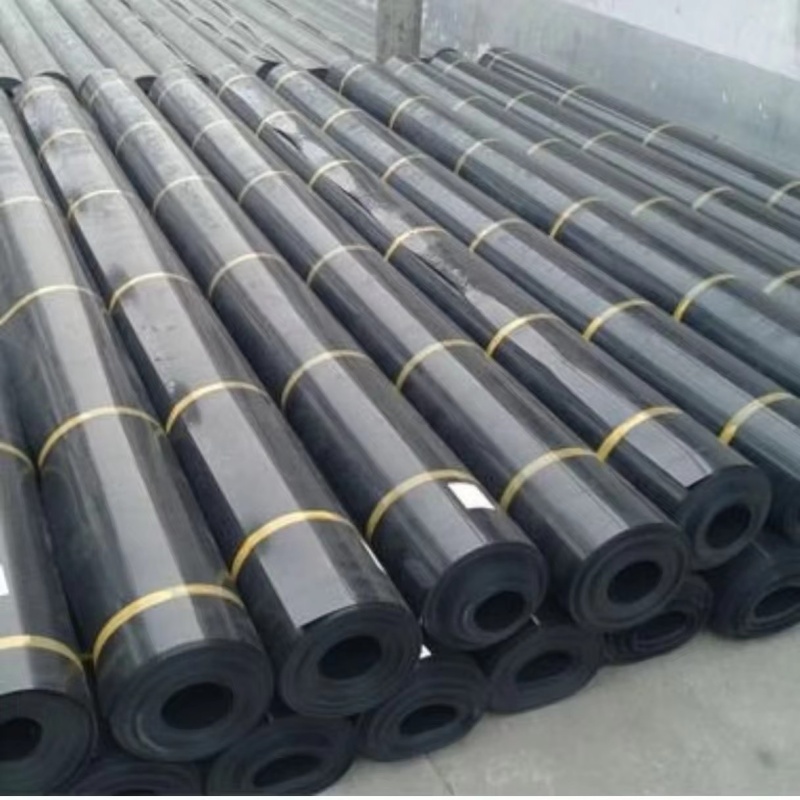

HDPE Membrane

1. Exceptional water-proofing: The dense structure can effectively prevent water and waste liquid from penetrating, and the water-proof effect is long-lasting and stable.

2. Excellent weather resistance and corrosion resistance: Resistant to acids, alkalis, salt fog, and temperature variations, with outstanding anti-aging performance.

3. High mechanical strength: Excellent tensile and tear strength, strong anti-puncture ability, and不易 damaged.

4. Environmentally friendly and durable: Made from eco-friendly HDPE material, it is non-toxic and harmless, has a long service life, low maintenance cost in the future, and offers high value for money.

Chapter 1: General Introduction

HDPE (High-Density Polyethylene) Membrane is a high-performance thermoplastic material made of HDPE resin through extrusion molding. It features excellent impermeability, corrosion resistance, and mechanical strength, with good aging resistance and environmental friendliness. Widely used in environmental protection, water conservancy, and other fields, it is a key material for anti-seepage projects. With the development of green infrastructure, HDPE membrane has become an indispensable product in ecological engineering, favored by engineering circles for its reliable performance and long service life.

Chapter 2: Physical Properties

Physical Property Index | Standard Value |

Density (g/cm³) | 0.940-0.965 |

Tensile Strength at Break (MPa) | ≥20 |

Elongation at Break (%) | ≥500 |

Tear Strength (kN/m) | ≥80 |

Hardness (Shore D) | 60-70 |

Chapter 3: Chemical Properties

Chemical Medium | Resistance Performance |

Acids (10% HCl, H₂SO₄) | Excellent, no obvious swelling or degradation |

Alkalis (10% NaOH, KOH) | Excellent, no cracking or strength loss |

Salts (5% NaCl, CaCl₂) | Good, no chemical reaction |

Organic Solvents (Ethanol, Acetone) | Good, slight swelling but recoverable |

Water | Excellent, impermeable and stable |

Chapter 4: Applications

HDPE membrane has a wide range of applications based on its excellent performance.

1. In environmental protection, it is mainly used for landfill anti-seepage, leachate collection, and sewage treatment pool lining to prevent soil and groundwater pollution.

2. In water conservancy engineering, it is applied to reservoirs, canals, and dam anti-seepage projects to reduce water loss.

3. In agriculture, it is used for greenhouse ground film and fish pond anti-seepage.

4. it is widely used in roof waterproofing of buildings, artificial lakes, and chemical storage tank bases, playing an important role in ecological protection and engineering construction.

Chapter 5: Installation

The installation of HDPE membrane requires strict adherence to operating specifications to ensure anti-seepage effect.

1. the base should be flat, clean, and free of sharp objects to avoid damaging the membrane.

2. the membrane is laid in a staggered manner, with an overlap width of 10-15cm. The welding method is mainly thermal fusion welding, using a special welding machine to ensure the welding seam strength is not lower than the base material.

3. After welding, air pressure testing is required to check for air leakage.

4. the membrane is covered and protected in time to prevent aging and damage. Professional construction teams and standardized operations are the key to ensuring installation quality.

Chapter 6: Price

The price of HDPE membrane is affected by multiple factors, including raw material cost, product thickness, quality grade, and purchase quantity.

1. The market price ranges from 8 to 25 yuan per square meter.

2. Thicker membranes (1.5mm-2.0mm) for engineering projects are usually priced between 12 and 25 yuan/square meter, while thinner membranes (0.5mm-1.0mm) for daily use are around 8-12 yuan/square meter.

3. Raw material price fluctuations and supply-demand relations will also affect the market price.

4. Bulk purchases can get certain discounts, and choosing high-quality products with stable performance is more cost-effective in the long run.

Chapter 7: Haoyang Environment's Advantages and Future Market

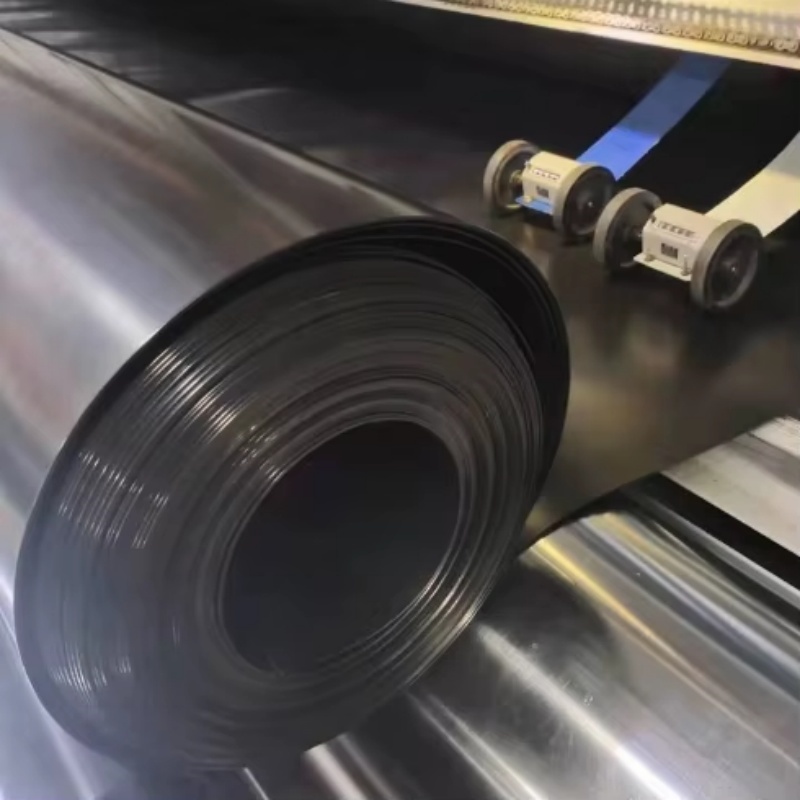

Haoyang Environment has obvious advantages in the HDPE membrane industry. It has advanced extrusion production lines, strict quality control systems, and products that meet national and international standards. The company has a professional R&D team, continuously optimizing product performance and developing environmentally friendly and high-performance HDPE membranes. It also provides one-stop services including product supply, technical guidance, and construction supervision.

Looking forward, with the promotion of national environmental protection policies and the development of new infrastructure, the demand for HDPE membrane in landfill, water conservancy, and ecological restoration projects will continue to grow. Haoyang Environment will seize market opportunities, expand production scale, and strengthen technological innovation to become a leading enterprise in the industry and contribute to green and sustainable development.