2mm Tailing Pond Liner

1.Excellent Puncture Resistance – Ideal for harsh environments with sharp tailings.

2.Superior Chemical Resistance – Withstands acidic and alkaline tailings effectively.

3.High Tensile Strength – Ensures long-term structural integrity under stress.

4.UV & Aging Resistant – Performs reliably in exposed outdoor conditions.

5.Low Permeability – Provides outstanding seepage control and environmental protection.

6.Certified & Durable – Meets international standards (e.g., GM13) for extended service life.

2mm Tailing Pond Liner

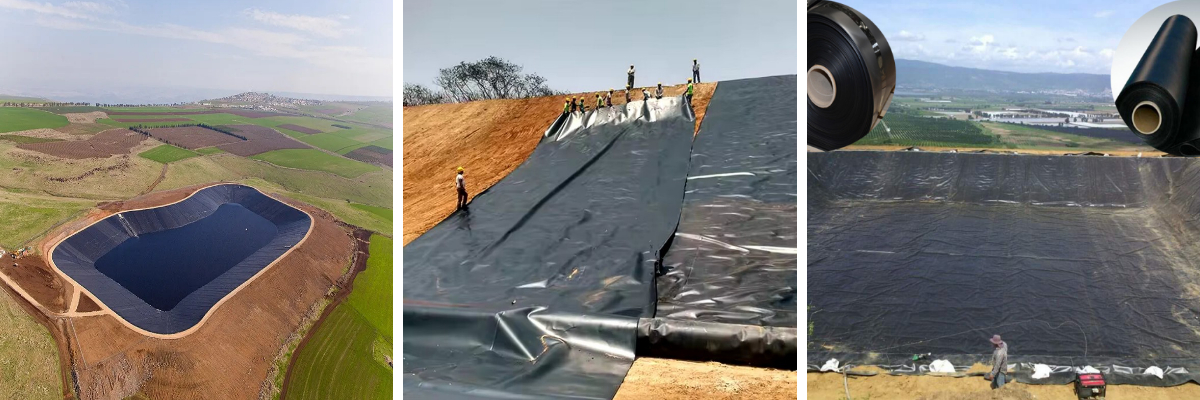

In the mining industry, the proper management of tailings—the slurry of water and finely ground rock left over after the extraction of valuable minerals—is both an environmental and operational priority. One of the most critical components in tailings management is the use of high-quality geomembranes as pond liners. Among these, the 2mm high-density polyethylene (HDPE) tailing pond liner has emerged as a gold standard, offering outstanding performance in terms of durability, impermeability, and chemical resistance. This article explores the key features, advantages, applications, and selection considerations of the 2mm tailings pond liner.

1. Why Tailings Require Robust Containment

Tailings often contain a mixture of water, residual chemicals, and finely ground ore, which may pose environmental risks if not properly contained. Leakage or seepage from tailings ponds can lead to groundwater contamination, soil degradation, and even catastrophic structural failures. Therefore, the need for a reliable containment system is critical—not only for regulatory compliance but also for environmental sustainability and operational safety.

A high-performance geomembrane liner, especially one made of HDPE, is essential in forming an impermeable barrier between tailings and the surrounding environment.

2. Key Features of a 2mm HDPE Tailings Pond Liner

The 2mm HDPE geomembrane is a thick, durable sheet designed to withstand the harsh conditions typical of tailings environments. Its unique properties make it particularly suitable for long-term containment applications. The core features include:

High Mechanical Strength: With excellent tensile and impact strength, the liner resists stretching, puncturing, and tearing, even under the pressure of heavy tailings loads.

Chemical Resistance: HDPE is inert to acids, alkalis, and a wide range of aggressive mining chemicals, ensuring it does not degrade over time.

Low Permeability: The liner forms an impermeable barrier, preventing the migration of liquids and contaminants.

UV Resistance: Designed to withstand prolonged exposure to sunlight, the liner retains its properties in exposed installations.

Thermal Stability: It performs reliably across a wide temperature range, making it suitable for mines in various climates.

Weldability: HDPE liners are easily seamed using thermal welding techniques, ensuring leak-proof joints.

3. Advantages of Using a 2mm Liner in Tailings Ponds

Choosing a 2mm thickness provides several key benefits compared to thinner alternatives:

Enhanced Safety Margin

A thicker liner provides a greater safety buffer against mechanical damage, including punctures from coarse tailings or sharp rocks.

Longer Service Life

The robust material structure of a 2mm HDPE liner ensures it can last for decades under proper conditions, reducing the frequency and cost of replacements.

Suitable for Harsh Conditions

In mining environments where chemical exposure, UV radiation, and thermal variation are common, a 2mm liner maintains integrity better than thinner versions.

High Resistance to Static and Dynamic Loads

Due to its increased thickness and tensile strength, the liner can handle the heavy load of accumulated tailings and potential equipment traffic during installation.

Compliance with Environmental Standards

Most international mining and environmental agencies recommend or require minimum liner thicknesses in tailings applications—2mm liners often meet or exceed these standards.

4. Applications Beyond Tailings Ponds

While primarily used in tailings containment, 2mm HDPE liners also find applications in:

Heap leach pads

Slurry storage ponds

Wastewater treatment lagoons

Evaporation ponds

Secondary containment areas for chemical storage

Their versatility makes them a preferred choice across various containment and environmental protection projects in mining, metallurgy, and heavy industry.

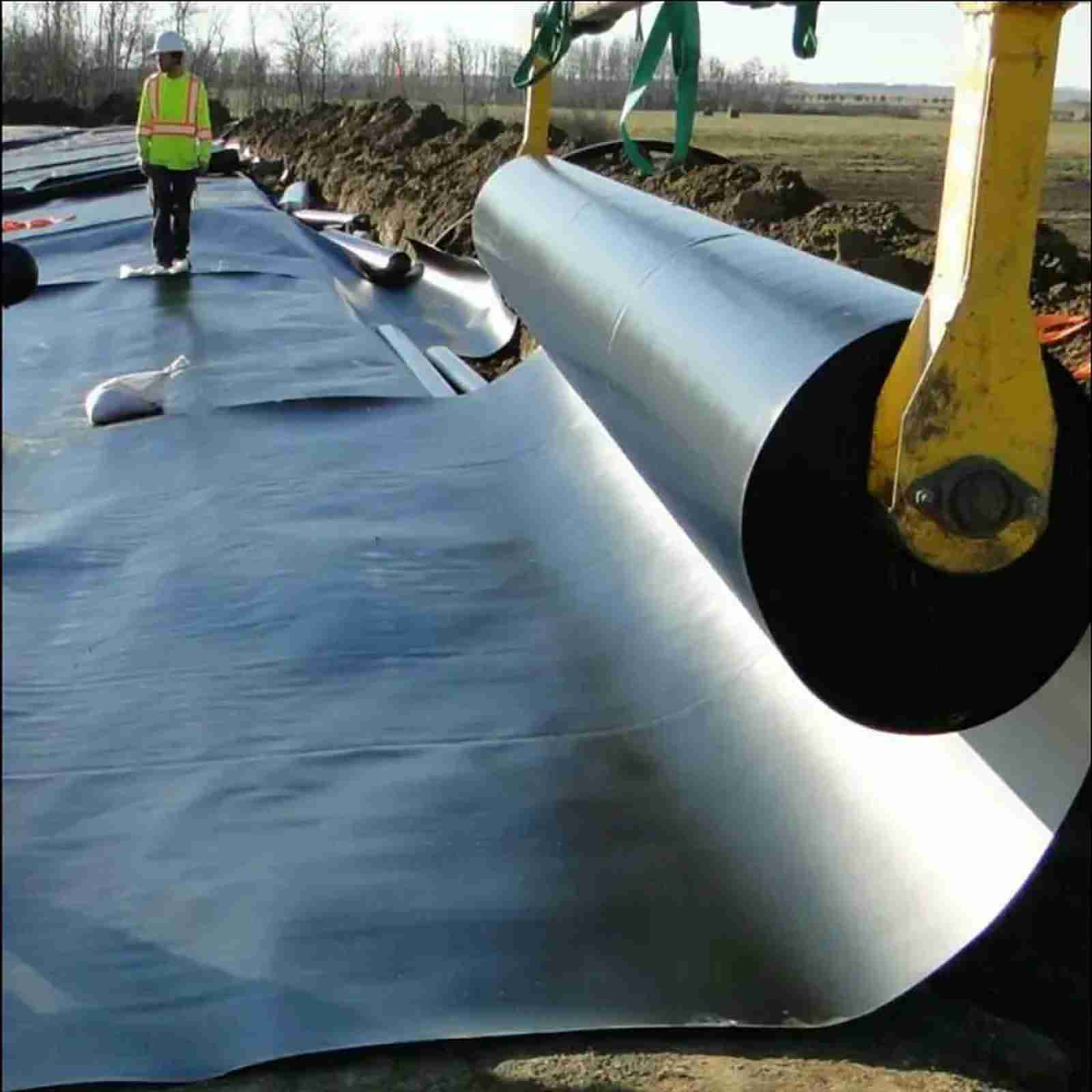

5. Installation Considerations

Proper installation is crucial to realizing the full potential of a 2mm HDPE tailings pond liner. Key steps include:

Surface Preparation: The subgrade must be compacted and free of sharp objects to prevent damage to the liner.

Panel Deployment: Large sheets are rolled out and positioned according to the design plan, often with overlaps for seaming.

Seaming/Welding: Specialized thermal welding machines are used to bond sheets together, ensuring leak-proof seams.

Testing: Non-destructive testing methods like air channel testing and vacuum box testing are conducted to ensure seam integrity.

Protection Layer: A layer of geotextile or sand may be placed over the liner to prevent damage during tailings deposition.

Working with experienced installers and using quality materials is essential to ensure long-term performance.

6. Choosing the Right Liner Supplier

When selecting a 2mm tailings pond liner, it is vital to partner with a reputable manufacturer who provides:

100% virgin HDPE raw materials

Certifications such as GRI-GM13, ISO9001, CE, etc.

Technical support and on-site guidance

Custom fabrication options and fast delivery

Proven project experience in mining sectors

At Haoyang Environmental Co., Ltd., for example, we specialize in producing high-quality HDPE geomembranes using virgin raw materials and advanced extrusion technology. Our liners have been widely used in large-scale mining projects across Asia, Africa, and South America, earning recognition for durability, compliance, and service excellence.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

In an industry where safety, environmental stewardship, and long-term performance are non-negotiable, the 2mm HDPE tailings pond liner stands out as a reliable and cost-effective solution. Its superior resistance to puncture, chemicals, and UV degradation makes it ideal for even the most demanding tailings storage facilities. As global regulations and environmental expectations grow stricter, investing in high-quality liners is not just smart—it’s essential.

Whether you're planning a new tailings pond or upgrading an existing one, choosing a 2mm HDPE liner from a trusted source ensures peace of mind, operational continuity, and environmental compliance for years to come.