1mm Tailing Pond Liner

1.Excellent Impermeability – Provides strong barrier against seepage, protecting soil and groundwater.

2.Chemical & UV Resistant – Withstands exposure to mining chemicals and sunlight without degradation.

3.Lightweight & Flexible – Easier to transport and install than thicker liners, ideal for large or remote sites.

4.Cost-Effective Choice – Lower material and logistics costs make it suitable for budget-conscious projects.

5.Fast Installation – Reduces welding time and equipment needs, improving project efficiency.

6.Ideal for Low-Load Conditions – Suitable for shallow ponds, temporary containment, or as part of composite systems.

1mm Tailing Pond Liner

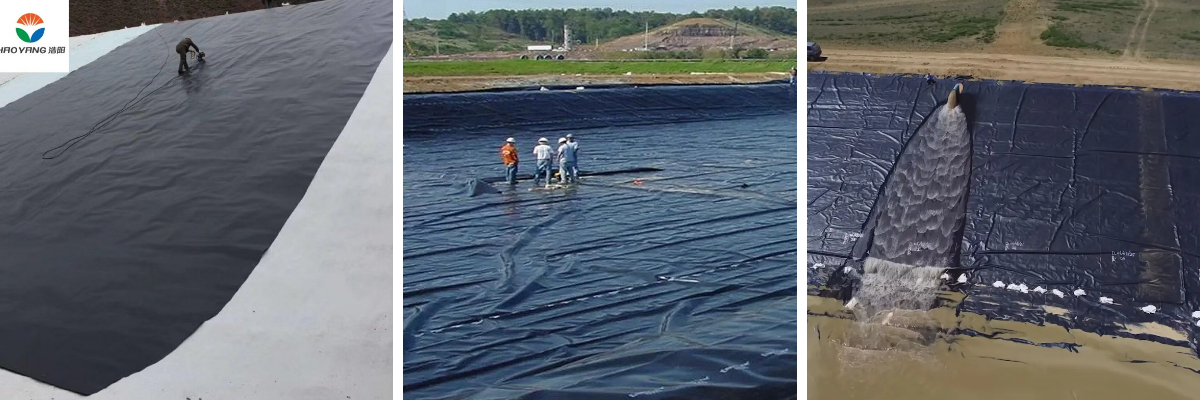

In modern mining operations, environmental protection and cost control are two critical factors that must go hand-in-hand. One of the key environmental measures taken by mining companies worldwide is the use of tailing pond liners to prevent seepage of contaminated water and heavy metals into the surrounding soil and groundwater. Among the various options available, the 1mm high-density polyethylene (HDPE) tailing pond liner offers a smart balance of performance, flexibility, and affordability.

This article explores the unique advantages, applications, and technical considerations of using a 1mm HDPE liner for tailing ponds, particularly in low to medium-risk containment environments.

1. Understanding the Role of Tailing Pond Liners

Tailings are the waste byproducts of mining processes that involve extracting valuable metals and minerals. These tailings are typically stored in engineered ponds or impoundments. Without an effective barrier, harmful substances such as arsenic, cyanide, and heavy metals may leach into the environment, causing irreversible damage.

A geomembrane liner, especially one made from HDPE, provides an impermeable barrier at the base and sides of the tailing pond, ensuring proper containment and compliance with environmental regulations.

2. Why Choose a 1mm HDPE Liner?

While thicker liners such as 1.5mm and 2.0mm are often used in high-risk or high-pressure applications, the 1mm HDPE tailing pond liner has distinct advantages in terms of cost, ease of handling, and suitability for certain project conditions. Here's why many engineers and project managers opt for the 1mm thickness:

Excellent Impermeability

Despite its relatively thin profile, a 1mm HDPE liner offers outstanding impermeability, effectively preventing water and leachate migration. It ensures compliance with environmental standards in containment applications with moderate pressure loads.

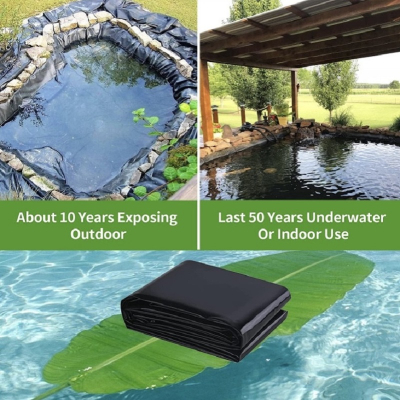

Chemical and UV Resistance

HDPE is known for its resistance to a wide range of chemicals including acids, alkalis, and salts, which are often found in tailings. The material is also UV stabilized, making it suitable for exposed applications without rapid degradation.

Lightweight and Flexible

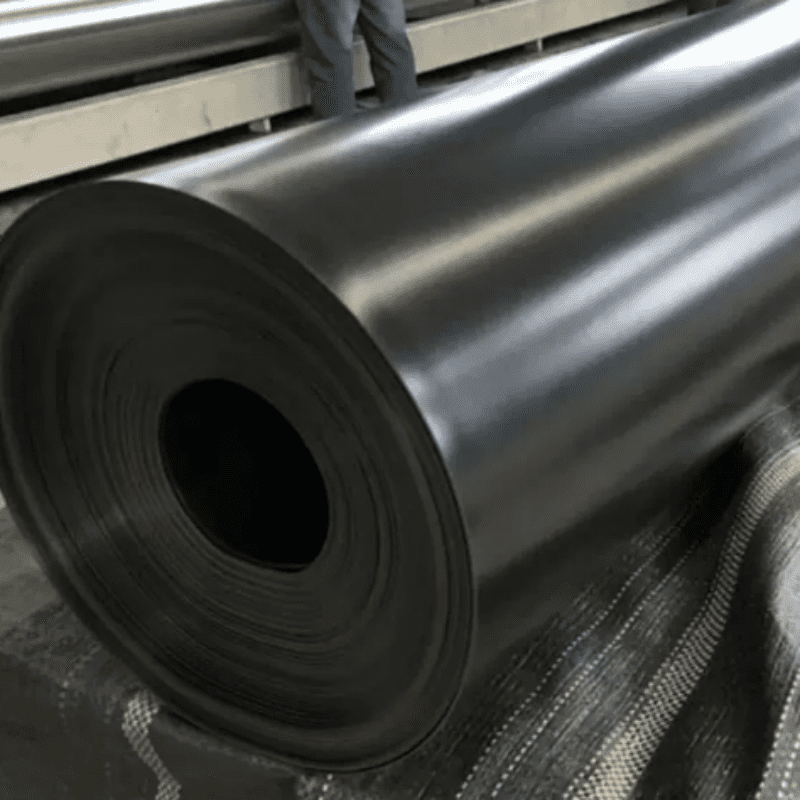

Compared to thicker liners, 1mm HDPE geomembranes are significantly lighter and more flexible. This simplifies transportation, deployment, and welding, especially in remote or mountainous mining sites where equipment access may be limited.

Cost-Effective for Large-Scale Projects

Due to lower raw material usage, 1mm liners are more economical per square meter. For large-area containment such as tailings ponds covering tens or hundreds of thousands of square meters, the cost savings on materials, logistics, and labor can be substantial.

Faster Installation

The reduced weight and roll size of 1mm liners enable faster handling and quicker seam welding during installation. This translates into shorter construction timelines and reduced equipment rental costs.

Environmentally Friendly

Using less material reduces the overall carbon footprint associated with manufacturing and transportation. In addition, HDPE is a recyclable material, contributing to sustainability goals in industrial operations.

3. Ideal Applications for 1mm Tailing Pond Liners

The 1mm HDPE liner is best suited for tailing pond applications that involve moderate containment pressures or temporary storage needs. Specific use cases include:

Temporary or Emergency Tailings Ponds

Ideal for rapid deployment during expansion phases or when permanent structures are under maintenance.Secondary or Redundant Containment Systems

Used as part of a composite liner system, such as a double-liner structure with leak detection between layers.Shallow Tailings Impoundments

Suitable for ponds with limited depth and low mechanical stress.Capping or Closure of Old Tailings Ponds

Used as an upper sealing layer during mine closure or environmental remediation projects.Low-Risk Mining Operations

Where tailings are relatively inert and containment conditions are stable.

4. Technical Specifications and Performance

Below are the typical performance parameters of a 1mm HDPE liner that meets international standards (e.g., GRI-GM13):

Property | Typical Value |

Thickness | 1.0 mm ± 10% |

Tensile Strength (Yield) | ≥ 16 kN/m |

Elongation at Break | ≥ 700% |

Puncture Resistance | ≥ 400 N |

Carbon Black Content | 2.0% – 3.0% |

UV Resistance | > 90% retained after 1600h |

Permeability | ≤ 1.0 × 10⁻¹³ cm/s |

These properties ensure that the liner can withstand the typical chemical and physical stresses of a tailings environment.

5. Installation Guidelines

While 1mm liners are easier to install than thicker materials, proper procedures must still be followed to ensure long-term effectiveness:

Surface Preparation: The subgrade should be smooth, compacted, and free of sharp debris.

Unrolling and Placement: Sheets should be deployed carefully with sufficient overlap (typically 100–150mm).

Welding: Thermal fusion welding (hot wedge or hot air) should be used for seams, followed by non-destructive testing.

Seam Testing: Methods such as vacuum box or air pressure testing verify seam integrity.

Protection Layer (optional): A geotextile or sand layer may be used to protect the liner from mechanical damage during tailings placement.

Working with certified installers and following standard QA/QC procedures are critical to project success.

6. Supplier Considerations

To ensure performance and reliability, it is crucial to source 1mm tailing pond liners from reputable manufacturers that offer:

100% Virgin HDPE Material

For maximum durability and chemical resistance.International Certification

Compliance with GRI-GM13, ISO9001, and CE standards.Customization and Fast Delivery

Fabrication of panels to custom sizes and timely shipment to meet project timelines.Technical Support

Guidance on material selection, deployment, and long-term maintenance.

For example, Haoyang Environmental Co., Ltd. provides high-quality HDPE geomembranes, including 1mm liners, that have been widely used in mining, wastewater, and environmental projects across Asia, Africa, and Latin America.

The 1mm HDPE tailing pond liner is a practical, efficient, and economical solution for a wide range of containment applications in mining. While it may not offer the extreme durability of thicker liners in high-stress environments, it provides more than sufficient performance for low to moderate containment needs—especially when combined with proper site design and construction practices.

For mining companies and contractors seeking to reduce costs without compromising on environmental protection, the 1mm liner is a smart choice that delivers both performance and value.