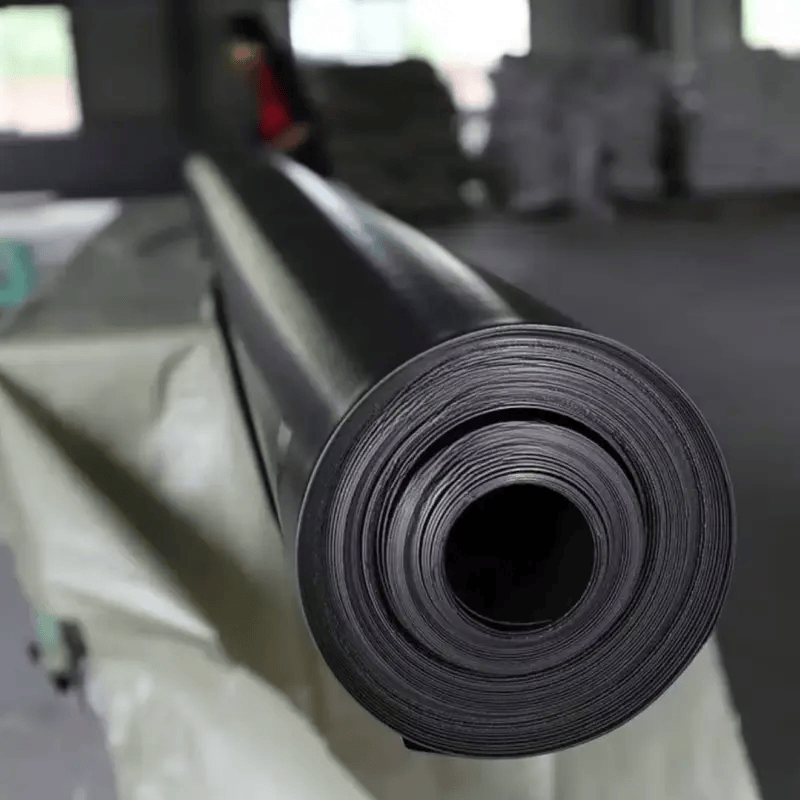

8m Wide 1.0mm HDPE Geomembrane

1. Excellent water-proofing performance: The 1.0mm thick HDPE material has excellent density and can effectively prevent liquid penetration.

2. Excellent durability: Resistant to ultraviolet rays, acid and alkali, and chemical corrosion, it does not easily become brittle at low temperatures.

3. Convenient construction: With an 8-meter width, it reduces the number of joints, and the heat welding construction is efficient.

4. High cost-effectiveness: The material has high strength and low loss, requires less maintenance in the future.

5. Environmentally friendly and reliable: Using environmentally friendly HDPE raw materials, there are no harmful substances released.

Product Introduction

8m Wide 1.0mm HDPE Geomembrane is mainly composed of 97.5% high-quality virgin polyethylene resin and 2.5% carbon black and other additives. It is processed through a three-layer co-extrusion technology. Its anti-seepage performance is outstanding, with a permeability coefficient much lower than that of clay. The product has excellent durability, is resistant to ultraviolet rayThe advantages of Haoyang Environments, acid and alkali corrosion, and can remain stable outdoors for a long time. With a width of 8 meters, it is convenient for construction, can significantly reduce joints, and lower the construction difficulty. It is widely applicable in scenarios such as landfill, water conservancy projects, and

Product parameters

| Item | Specification | Test Standard |

| Thickness | 1.0mm | ASTM D5199 |

| Width | 8m | / |

| Density | ≥0.94g/cm³ | ASTM D1505 |

| Tensile Yield Strength | ≥15N/mm (MD/TD) | ASTM D6693 |

| Tensile Breaking Strength | ≥27N/mm (MD/TD) | ASTM D6693 |

| Elongation at Break | ≥550% (MD/TD) | ASTM D6693 |

| Right-angle Tear Strength | ≥125N | / |

| Puncture Resistance | ≥270N | / |

| Carbon Black Content | 2.0%-3.0% | / |

| Water Vapor Transmission Coefficient | ≤1.0×10⁻¹³g·cm/cm²·s·Pa | / |

| Environmental Stress Crack Resistance | ≥1500h | / |

| Operating Temperature Range | -60℃ - +60℃ | / |

Application fields

1. Leachate prevention in landfill sites: As the core waterproof layer, it is laid at the bottom and around the landfill area to prevent the infiltration of leachate and pollution of soil and groundwater. With an 8-meter width to reduce seams and lower the risk of leakage, it is suitable for complex sites and ensures the environmental compliance of the landfill.

2. Water conservancy project waterproofing: Used for reservoirs, dams, channels, etc., it blocks water leakage and improves water resource utilization. Its weather resistance is adapted to the outdoor water environment. With a 1.0mm thickness, it meets the strength requirements for water conservancy project waterproofing and ensures the long-term stability of the project.

3. Aquaculture facilities: Laid at the bottom of the aquaculture ponds to prevent water leakage and the infiltration of harmful substances from the soil, maintaining stable water quality. The corrosion resistance is suitable for the chemical environment of the aquaculture water, helping to increase aquaculture benefits.

4. Mining waterproofing project: Applied to tailings ponds, heap leaching pools, etc., it blocks the infiltration of mine waste liquid and avoids pollution of the surrounding environment. Its acid and alkali resistance adapts to the complex media of mining, ensuring the environmental safety and production of the mining industry.

5. Construction of artificial wetlands: As the base material for waterproofing, it fixes the wetland structure and prevents sewage leakage. With an 8-meter width for easy large-scale laying, it has strong terrain adhesion and helps the ecological function of the artificial wetland to be fully exerted.

The future development of the global environmental protection field

1. Deepening application of environmental protection engineering: In landfill sites, its anti-seepage performance continuously safeguards the soil and groundwater, preventing leachate pollution. In sewage treatment plants, it effectively blocks the leakage of sewage, helping to purify water quality. In the future, as environmental protection standards rise, its demand will be more vigorous and its application will be more refined. For example, it will play a greater role in the disposal of hazardous waste.

2. Expansion of emerging markets: In the infrastructure construction boom in developing countries, a large number of water conservancy projects and agricultural irrigation facilities are being constructed. The 8-meter-wide material is convenient for large-scale laying and the 1.0mm thickness is suitable for various anti-seepage requirements. It will take root widely in these emerging markets and drive the expansion of market scale.

3. Technological innovation drives: The research and development direction will focus on improving material performance, such as enhancing the ability to resist ultraviolet rays to extend the outdoor service life, and optimizing the welding process to make the joints more secure. At the same time, new products with self-repairing functions may be developed to further improve the reliability of anti-seepage.

4. Sustainable development assistance: The global advocacy of sustainable development. The HDPE geotextile membrane's recyclable feature aligns with the concept. In the future, it will be more widely applied in green buildings, ecological restoration and other projects. While reducing environmental impact, it will contribute to ecological protection and construction.

The advantages of Haoyang Environment

1. Outstanding product performance: Selecting high-quality virgin polyethylene resin and combining it with advanced three-layer co-extrusion technology, its water vapor permeability coefficient K is <= 1.0 * 10-13 cm/(cm2·s·Pa), and the waterproofing effect is top-notch. The tensile strength at break reaches 28 MPa, the elongation at break is 700%, and the mechanical strength is excellent, which can effectively cope with various complex environments and external forces.

2. Excellent durability: During production, carbon black, anti-aging agents, etc. are added to the product, making it possess outstanding anti-aging, anti-ultraviolet and anti-decomposition capabilities. It can be used in an outdoor environment for a long time without covering, and the material service life can last up to 50 to 70 years, significantly reducing the cost of later replacement and maintenance.

3. Convenient construction characteristics: The 8-meter wide design is ingenious. During construction, it can significantly reduce the number of joints, lower the risk of leakage caused by improper joint treatment, and significantly improve construction efficiency. At the same time, using the hot-melt welding process, the weld strength is high, the operation is convenient and fast, and various laying forms can flexibly meet the waterproofing requirements of different projects, and can easily adapt to various complex construction sites.

4. Advanced production and testing system: Haoyang Environment has an over 230-acre production base, 40,000 square meters of standardized workshops, and 26 modern production lines. The production strength is strong. Moreover, it has a CNAS-certified laboratory equipped with top-notch precision testing instruments to conduct comprehensive and strict product testing from the source, ensuring that the product quality meets various high standards and specifications, allowing customers to use with greater peace of mind.