HDPE Geomembrane Pond Liner For Aquaculture

1. Anti-seepage and water retention, with an extremely low permeability coefficient, can reduce water leakage, stabilize the water level in the tank, and lower the cost of water replenishment.

2. Safe and harmless, in line with food-grade standards, without the release of harmful substances, and does not affect the growth of fish and shrimp or the safety of aquatic products.

3. Easy to clean and manage, with a smooth surface, it is not prone to the growth of moss and dirt, making it convenient to clean the bottom of the tank and reducing the risk of diseases.

4. Durable and resistant, able to withstand water pressure, ultraviolet rays, and corrosion from the breeding environment, with a long service life, and reducing the cost of frequent replacements.

HDPE Geomembrane: The Guardian of Aquaculture Waters

I: Introduction to HDPE Geomembrane

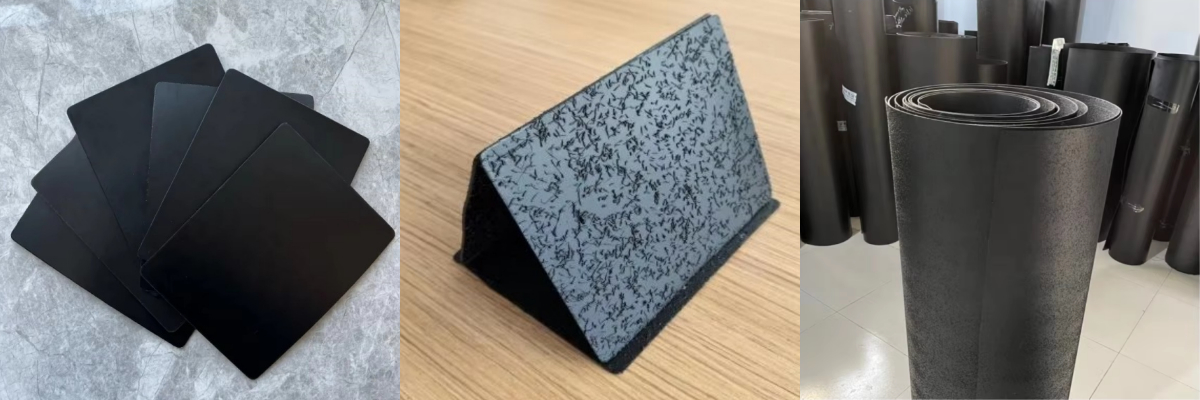

HDPE geomembrane, also known as high-density polyethylene geomembrane, is mainly made of 97.5% high-density polyethylene. This highly crystalline, non-polar thermoplastic resin endows the geomembrane with basic physical properties and chemical stability. Additionally, about 2.5% of carbon black, anti-aging agents, antioxidants, UV absorbers, stabilizers, etc., act as "special capabilities" for the geomembrane.

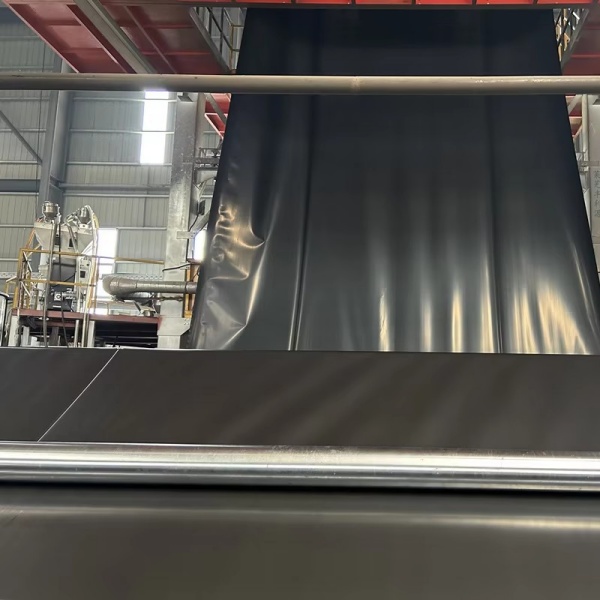

During the production process of HDPE geomembrane, advanced three-layer co-extrusion technology is adopted to integrate these carefully proportioned raw materials, resulting in a geotextile membrane with uniform structure and excellent performance, making its thickness, strength and other performance indicators more stable, and enabling it to reliably function in various application scenarios.

II: Physical and Chemical Properties

(1) Physical Performance Demonstration

The physical properties of HDPE geomembranes are outstanding, which is the key factor enabling their wide application in various engineering projects. The following presents the main physical performance data in a table.

| performance index | unit | numerical value |

| Tensile breaking strength | N/mm | ≥27 |

| yield strength | N/mm | ≥15 |

| Puncture resistance strength | N | ≥320 |

| elongation at break | % | ≥700 |

| Right-angle tear strength | N | ≥125 |

| density | g/cm³ | 0.93 - 0.97 |

(2) Chemical Performance Analysis

The HDPE geomembrane has outstanding chemical properties, being resistant to acids and alkalis within the pH range of 2 to 13, and resistant to corrosion by chemical substances in sewage and leachate. It contains anti-aging components that can resist ultraviolet oxidation, and no harmful substances are released. It meets environmental protection requirements and is suitable for various scenarios.

III: Multi-field Applications, Demonstrating the Strength of Geomembranes

(1) Environmental Sanitation Field

In landfill sites, it is laid at the bottom and the slopes to form an impenetrable anti-seepage barrier. During the landfill process, a large amount of leachate is produced, which contains various harmful substances such as heavy metals and organic pollutants. HDPE geomembrane, with its extremely low permeability coefficient and excellent chemical stability, effectively prevents the leachate from seeping into the ground, protecting the soil and groundwater from pollution. In sewage treatment plants, whether in regulating ponds, aeration ponds or sedimentation ponds, HDPE geomembrane plays an important role in anti-seepage.

(2) Hydraulic Engineering Field

In the anti-seepage projects of river, lake and reservoir dams, the geomembrane is laid on the upstream surface or inside the dam to prevent water body seepage and enhance the stability of the dam, reducing the risk of dam collapse due to seepage. In the anti-seepage of water channels, the application of geomembrane significantly reduces the leakage loss of water resources during transportation and improves the efficiency of water resource utilization. Moreover, in some small-scale hydraulic engineering projects such as ponds and reservoirs, the geomembrane is also widely used due to its simple construction and low cost.

(3) Municipal Engineering Field

In subway construction, the geomembrane is used for tunnel lining and the bottom of stations to prevent groundwater seepage, ensuring a dry and safe environment for subway operation and avoiding damage to tracks and equipment due to water accumulation. In underground engineering of buildings, such as basements and underground parking lots, the geomembrane can effectively prevent groundwater seepage. In the application of sewage pipe linings, the geomembrane can repair aged or damaged pipes, enhance the anti-seepage performance of the pipes, and prevent sewage leakage from polluting the surrounding soil and groundwater.

(4) Agricultural and Aquaculture Field

In aquaculture ponds, the geomembrane serves as the inner lining of the pond, with a remarkable waterproof effect, which can effectively maintain the water level of the pond, reduce the frequency of water replacement, and reduce water resource waste. In the construction of biogas tanks, the anti-seepage performance of the geomembrane ensures the effective collection and storage of biogas, promoting the utilization of rural clean energy and promoting the green and sustainable development of agriculture.

Ⅳ: The Secret Behind Prices - Analysis of Influencing Factors

The price of HDPE geotextile membranes is not fixed but is influenced by multiple factors, resulting in a certain fluctuation range in the market price.

(1) Raw material cost

The main raw material for HDPE geotextile membranes is high-density polyethylene (HDPE), and its price fluctuates due to various factors such as international crude oil prices, production processes, and output.

(2) Production process and technical level

The production process and technical level have a crucial impact on the price of HDPE geotextile membranes. Advanced production processes, such as three-layer co-extrusion technology, can make the performance of the geotextile membranes more stable and the quality more reliable. At the same time, high-level technical support can optimize the production process, increase production efficiency, and reduce the defect rate. However, this also means higher equipment investment and technical research and development costs.

(3) Market supply and demand relationship

The market supply and demand relationship is a direct factor affecting the price of HDPE geotextile membranes. When the market demand for HDPE geotextile membranes is strong, the price will rise. Conversely, when the market supply is excessive, causing the price of geotextile membranes in that region to decline.

(4) Brand influence

Brand has an important influence in the HDPE geotextile membrane market. Well-known brands often accumulate a good quality reputation and credibility through long-term market cultivation. Some international well-known brands' geotextile membranes, although priced higher than ordinary brands, are still favored by many large-scale projects due to their reliable quality and guaranteed after-sales service.

(5) Transportation cost

The production and sales of HDPE geotextile membranes often involve long-distance transportation. Transportation cost is affected by factors such as transportation distance, transportation methods, and oil prices during transportation.

(6) Seasonal factors

Seasonal factors also have an impact on the price of HDPE geotextile membranes. In some regions, the winter heating season and the summer rainy season may affect the construction progress and start-up rate.

Ⅴ: Global Application Cases, Witnessing Successful Practices

HDPE geomembranes have achieved numerous successful applications in the global field of aquaculture and related areas. Here are three typical cases for your reference.

(1) A Large-scale Fish Farming Base in the United States

A large-scale fish farming base in the United States has a vast area for farming. At the beginning of its construction, it faced serious leakage problems in the ponds and unstable water quality. After using HDPE geotextile membranes as the inner lining of the ponds, the situation was greatly improved. The excellent anti-seepage performance of the geotextile membranes effectively solved the problem of pond leakage, maintained stable water levels, and significantly reduced the frequency of water replacement.

(2) A Shrimp Farming Facility in Indonesia

Indonesia is a major country for shrimp farming. A shrimp farming facility in this country achieved great success after applying HDPE geo membranes. Shrimp farming requires strict water quality and pond environment. Previously, due to poor pond bottom quality, the water body was prone to pollution from harmful substances in the soil, resulting in frequent shrimp diseases and low survival rates. After laying HDPE geotextile membranes, the soil and water body were effectively separated, preventing the spread of bottom pathogenic organisms to the water body, ensuring the stability of the water body's chemical environment.

(3) A Tilapia Farming Project in Australia

An Australian tilapia farming project is located in an arid area and has precious water resources. Before introducing HDPE geotextile membranes, the ponds suffered from severe water evaporation and leakage, and the cost of water for farming was high, which restricted the expansion of the farming scale. The extremely low permeability coefficient of HDPE geotextile membranes effectively prevented water leakage and reduced water evaporation, significantly saving water resources. The anti-ultraviolet property of the geotextile membranes enables it to maintain stable performance even under the strong sunlight in Australia.

Ⅵ: Choose Haoyang Environment, Choose Quality and Assurance

Among the numerous HDPE geotextile membrane suppliers, Haoyang Environment stands out and becomes the preferred choice for many customers. This is due to its numerous significant advantages.

(1) Advanced Production Technology

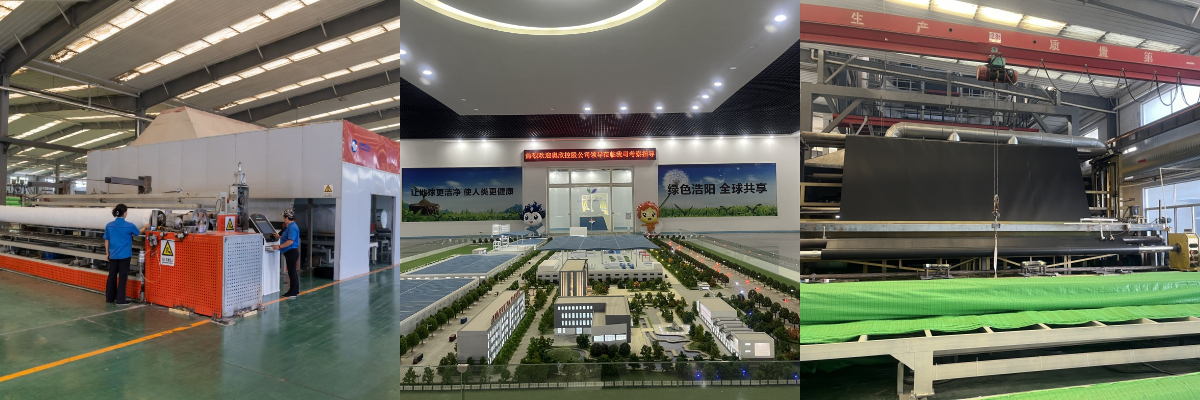

Haoyang Environment has over 20 modern production lines, using international advanced three-layer extrusion technology, combined with advanced automated feeding systems, ensuring the stability and uniformity of product quality from the source.

(2) Strict Quality Control

Haoyang Environment has established advanced laboratories to conduct strict inspections on raw materials and finished products, following a strict quality control system from the source to the end.

(3) Comprehensive After-sales Service

Haoyang Environment provides customers with a complete system solution for pre-sale, in-sale, and post-sale. For problems such as geotextile membrane leakage that may occur during project operation, it also offers professional testing and repair services.

(4) Rich Industry Experience

Since its establishment in 2008, Haoyang Environment has deeply focused on the field of geotechnical materials, undertaking over 100 domestic projects and serving over 7,000 global customers. It has accumulated rich experience in environmental protection and sanitation, water conservancy projects, municipal engineering, agriculture and aquaculture, etc.

Ⅶ: Face Up to Shortcomings and Look Forward to Future Development

(1) Discussion of Existing Shortcomings

Although HDPE geomembranes have many advantages, there are still some shortcomings in practical applications. Their puncture resistance is relatively good, but there is still a risk of being punctured when facing extreme sharp objects and high-intensity external force impacts. For example, in landfill sites, if the garbage contains large sharp metal items, they may penetrate the geomembrane, resulting in failure of the anti-seepage function. Geomembranes are exposed to harsh environments such as ultraviolet rays, high temperatures, and high humidity for a long time, accelerating aging and affecting their physical and chemical properties, shortening their service life.

(2) Future Development Outlook

In the future, HDPE geomembranes are expected to make breakthroughs and develop in multiple aspects. In material improvement, researchers will strive to enhance its puncture resistance, aging resistance, etc., and add new additives to enable the geomembrane to better adapt to various complex environments. As the importance of environmental protection and sustainable development in various industries continues to increase, HDPE geotextile membranes will expand their applications in emerging fields such as the new energy sector. Geomembranes will also be integrated with new technologies such as the Internet of Things and big data, embedding sensors in the geo membrane to achieve real-time monitoring of its usage status and timely detection of leakage, damage, etc. providing more reliable guarantees for various engineering constructions.