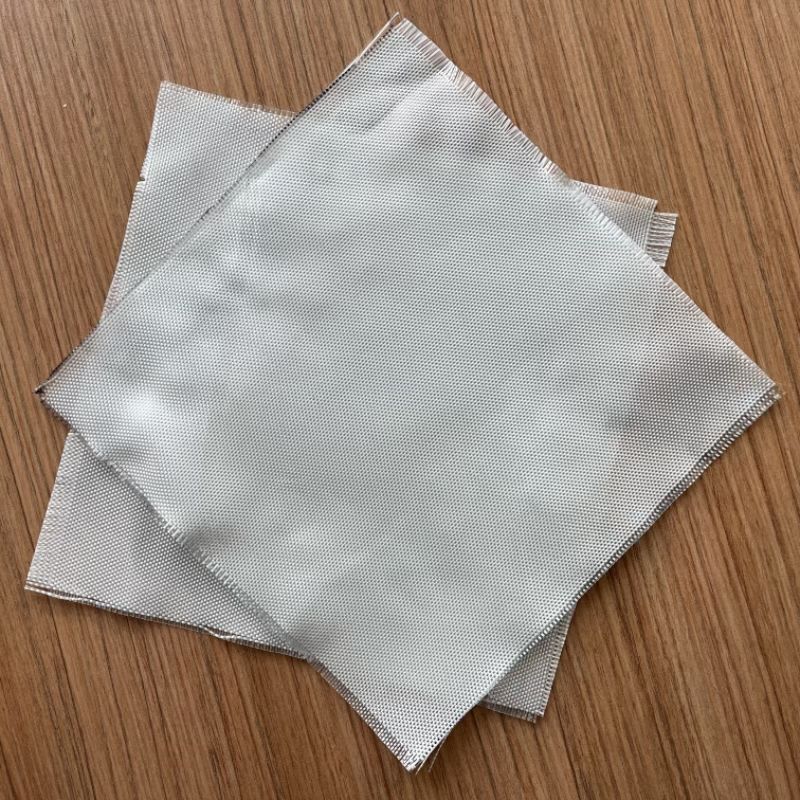

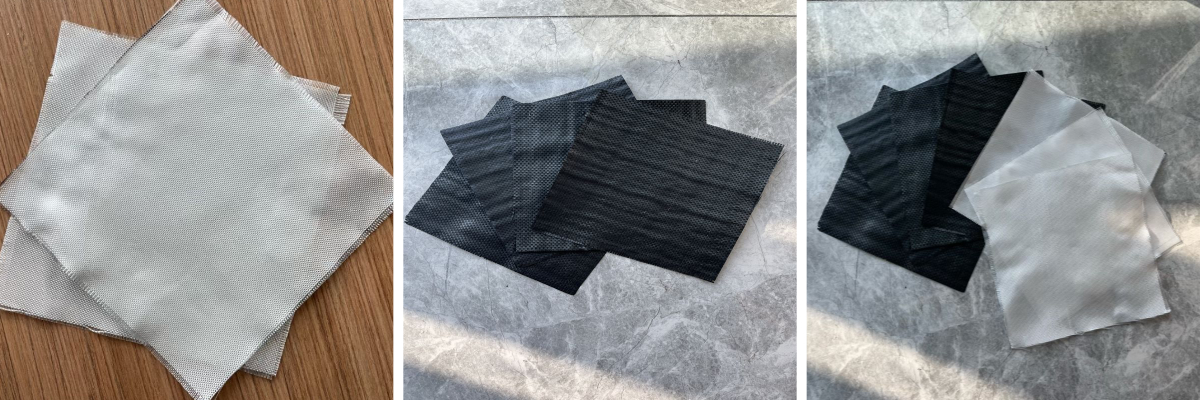

Woven Geotextile Fabric

High Strength & Load Capacity: Woven polypropylene/polyester for roads, embankments, retaining walls.

Puncture & Tear Resistant: Withstands sharp rocks - ideal for landfills, mining.

UV Resistant & Durable: Decades-long performance in exposed areas.

Soil Stabilization: Prevents mixing - perfect for roads, railways.

Drainage Control: Manages water flow in canals, dams, erosion control.

Product Introduction

Woven Geotextile is a synthetic fabric made from high-strength, low-elongation filament fibers such as polypropylene and polyester through a weaving process. Typically, it is woven from two sets of filaments. Classified by its intended use, geotextile varieties include single-layer woven geotextile (also known as silt filter fabric), double-layer geotextile (also known as geotextile mat), and woven geomembrane. It is suitable for applications such as slope protection and bank reinforcement in rivers, seas, and coastal areas, as well as water collection areas, revetment protection in harbors, flood prevention and emergency response, reinforcement of embankments and dykes, foundation stabilization of soft soil, construction of cofferdams, and various erosion control projects.

Product Specifications

Properties | Test Method | GM13 Test Value | Testing Frequency | ||||||

Thickness (min. ave.) | 0.75mm | 1mm | 1.25mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | (minimum) | |

nom. | nom. | nom. | nom. | nom. | nom. | nom. | Per roll | ||

lowest individual of 10 values | D5199 | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |

Formulated Density mg/l (min.) | D 1505/ D 792 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 90,000kg |

Tensile Properties (1) (min. ave.) | D 6693 Type IV | 9,000kg | |||||||

. yield strength | 11kn/m | 15kn/m | 18kn/m | 22kn/m | 29kn/m | 37kn/m | 44kn/m | ||

. break strength | 20kn/m | 27kn/m | 33kn/m | 40kn/m | 53kn/m | 67kn/m | 80kn/m | ||

. yield elongation | 12% | 12% | 12% | 12% | 12% | 12% | 12% | ||

. break elongation | 700% | 700% | 700% | 700% | 700% | 700% | 700% | ||

Tear Resistance (min. ave.) | D 1004 | 93N | 125N | 156N | 187N | 249N | 311N | 374N | 20,000 kg |

Puncture Resistance (min. ave.) | D 4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N | 20,000 kg |

Stress Crack Resistance (2) | D5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | per GRI-GM10 |

(App.) | |||||||||

Carbon Black Content (range) | D 4218 (3) | 2.0-3.0% | 9,000kg | ||||||

Oxidative Induction Time (OIT) (min. ave.) (5) (a) Standard OIT | D 3895 D 5885 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 90,000kg |

— or —(b) High Pressure OIT | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | ||

Oven Aging at 85°C (5), (6) | D 5721 D 3895 D 5885 | per each formulation | |||||||

(a) Standard OIT (min. ave.) - % retained after 90 days — or — | 55% | 55% | 55% | 55% | 55% | 55% | 55% | ||

(b) High Pressure OIT (min. ave.) - % retained after 90 days | 80% | 80% | 80% | 80% | 80% | 80% | 80% | ||

(a) Standard OIT (min. ave.) | D 3895 D 5885 | 50% | 50% | 50% | 50% | 50% | 50% | 50% | per each formulation |

— or — | |||||||||

(b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | |||||||||

Product Performance

1), High tensile, tear, puncture resistance, and other mechanical strengths make it more than twice as strong as geotextiles of equivalent weight made from short fibers. Specifically, it excels in resisting puncture and top bursting forces, with a strength reaching 2200 Newtons or more. In applications such as stone revetment, it effectively prevents irregular stones from impacting the fabric surface.

2), Relying on the mutual compression of warp and weft yarns to maintain structural stability, high-strength woven geotextile is particularly suitable for reinforcement, strengthening, and isolation applications.

3), Excellent chemical resistance; corrosion resistance

Application Scenarios

1). Road and Railway Construction

- Subgrade Reinforcement:

- Stabilizes weak soils and distributes loads to prevent rutting and cracking in highways, airports, and railway tracks.

- Separation Layer:

- Prevents intermixing of soil and aggregate layers, maintaining structural integrity of pavements.

2). Erosion Control

- Slope and Embankment Protection:

- Reinforces steep slopes, riverbanks, and coastal areas to resist erosion from water flow or wind.

- Often paired with gabions or riprap for added stability.

- Retaining Walls:

- Reduces soil pressure and filters water behind walls to prevent buildup of hydrostatic pressure.

3). Hydraulic and Coastal Engineering

- Dam and Canal Liners:

- Protects against seepage and erosion while allowing controlled drainage.

- Revêtments and Breakwaters:

- Strengthens structures against wave action and tidal forces in coastal zones.

4). Landfill and Waste Containment

- Landfill Liners and Covers:

- Acts as a protective layer over geomembranes, preventing puncture from sharp waste materials.

- Facilitates gas venting and leachate drainage in landfill capping systems.

- Mining and Tailings Ponds:

- Stabilizes containment structures for mining waste and chemical byproducts.

5). Agriculture and Infrastructure

- Drainage Systems:

- Enhances subsurface drainage in agricultural fields, sports fields, or urban landscapes.

- Temporary Access Roads:

- Provides a stable base for construction vehicles on soft or muddy terrain.

Why choose Haoyang Geomembrane?

1. Imported Raw Materials

High-quality raw materials sourced from **Saudi Arabia** ensure superior product performance and consistency from the source.

2. World-Leading 10m Blown Film Production Line

Equipped with advanced five-layer co-extrusion technology, capable of producing both smooth and textured geomembranes with a maximum width of 10 meters.

3. Direct-from-Factory Production

As a manufacturer, we guarantee premium quality while offering the most competitive prices by eliminating middlemen.

4. Fast Delivery

High daily output of 70 tons ensures timely delivery to meet urgent project timelines.

5. One-Stop Solution

Beyond manufacturing and sales, we provide **professional project construction teams** to deliver end-to-end solutions for seamless project execution.