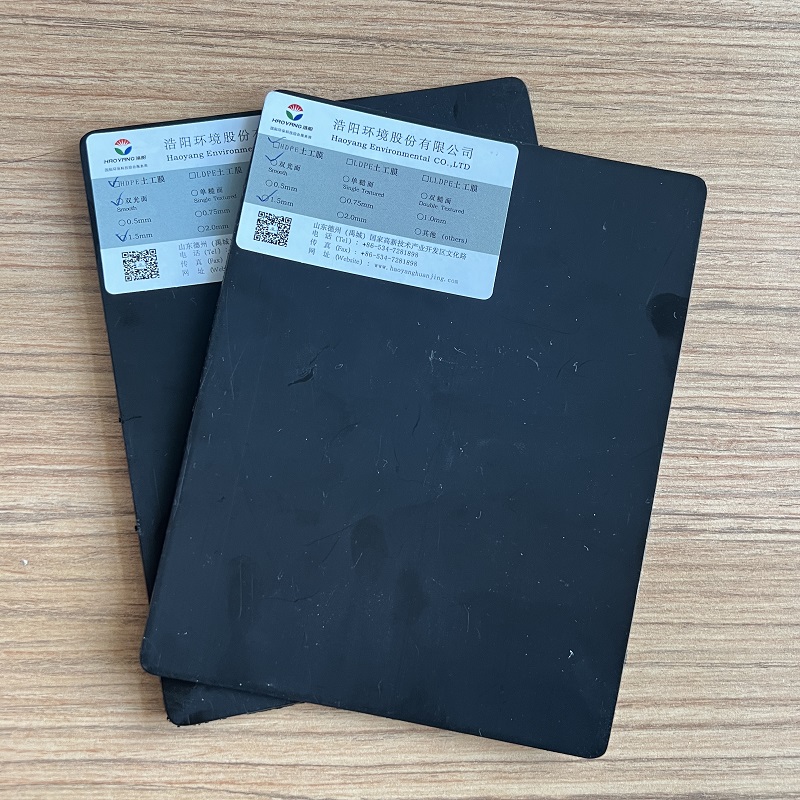

60mil LDPE Geomembrane

Unrivaled Puncture Resistance: Withstands sharp objects and abrasive materials, reducing installation and operational risks.

Exceptional Chemical Diversity: Resists acids, alkalis, and hydrocarbons, making it ideal for industrial waste and mining applications.

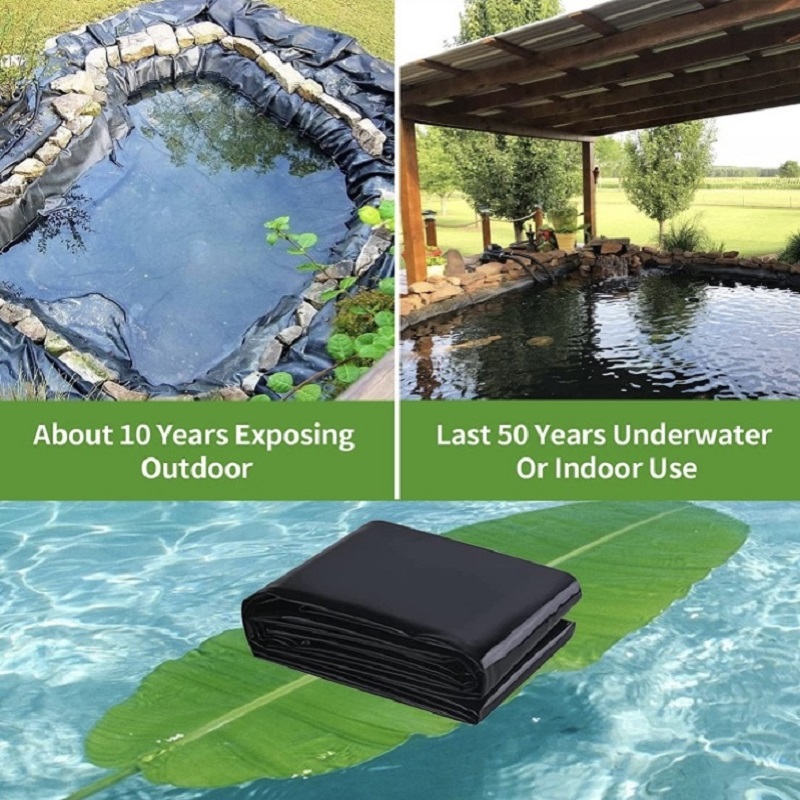

Proven Longevity: Offers 50+ years of reliable performance with minimal maintenance, lowering lifecycle costs.

60mil LDPE Geomembrane: Engineering Excellence for Demanding Containment Applications

Introduction

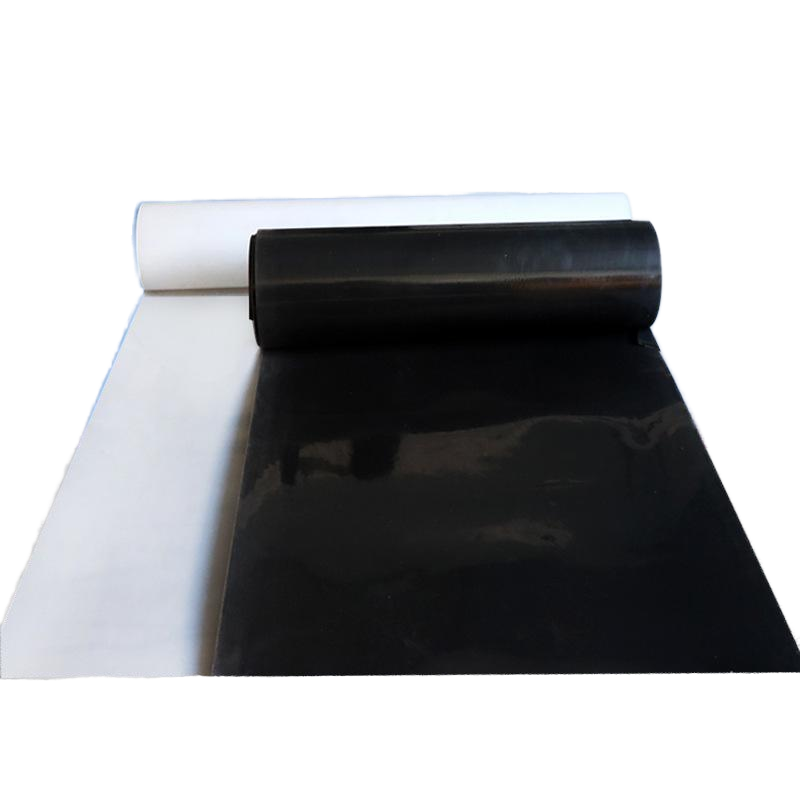

The 60mil LDPE geomembrane (1.5 mm thickness) represents a heavy-duty solution in geosynthetic technology, engineered to withstand extreme mechanical, chemical, and environmental stresses. As projects demand greater durability and longevity, this thicker LDPE variant emerges as a critical component for infrastructure resilience. This article delves into the technical attributes, applications, and competitive edge of 60mil LDPE geomembranes, supported by industry-standard performance metrics and real-world use cases.

1. Material Composition and Technical Specifications

LDPE geomembranes are extruded from polyethylene resins, with the 60mil thickness enhancing mechanical robustness while retaining flexibility. Below are the key parameters defining its performance envelope:

Table 1: Key Physical Properties of 60mil LDPE Geomembrane

| Property | Specification | Unit | Test Method |

Thickness | 60 mil (1.5 mm) | mil/mm | ASTM D5199 |

Density | 0.94 g/cm³ | g/cm³ | ASTM D1505 |

Tensile Strength | 30 MPa (MD/TD) | MPa | ASTM D6693 |

Elongation at Break | 600% (MD/TD) | % | ASTM D6693 |

Puncture Resistance | 600 N | N | ASTM D4833 |

Carbon Black Content | 2–3% | % | ASTM D1603 |

Hydrostatic Resistance | >300 m | m | ASTM D5385 |

UV Resistance | 1,500+ hours | Hours | ASTM G154 |

Low-Temperature Flexibility | -70°C (-94°F) | °C/°F | ASTM D5322 |

Key Insights:

The 30% thicker profile compared to 40mil LDPE enhances puncture resistance by 50%, critical for applications with sharp debris.

Hydrostatic resistance of 300+ meters ensures containment in high-head pressure scenarios like reservoirs and tailings dams.

2. Applications in High-Stress Environments

The 60mil LDPE geomembrane excels in industries where containment failure is not an option.

2.1 Mining and Heavy Industry

Tailings Storage Facilities (TSFs): Resists abrasion from coarse ore particles and chemical leachates.

Heap Leach Pads: Withstands cyclic loading from ore piles and aggressive precipitation (e.g., sulfuric acid in copper extraction).

2.2 Waste Management

Municipal Landfill Liners: Provides redundancy against leachate migration in large-scale facilities.

Ash Ponds: Contains coal ash slurry, resisting alkaline conditions (pH 10–12).

2.3 Hydraulic Structures

Canal Liners: Prevents seepage in irrigation canals with high flow velocities.

Reservoirs: Withstands wave action and UV exposure in arid regions.

2.4 Oil and Gas

Secondary Containment Berms: Protects ecosystems from hydrocarbon spills.

Fracking Water Ponds: Resists brine solutions and high salinity (up to 25% NaCl).

3. Performance Advantages Over Competitors

The 60mil LDPE geomembrane outperforms alternatives like HDPE and PVC in critical aspects.

3.1 Superior Puncture and Tear Resistance

The 1.5 mm thickness provides a 60% higher puncture resistance (600N vs. 400N for 40mil LDPE), making it ideal for unpaved or rocky substrates.

Case Study: A 2022 study by the Geosynthetic Institute compared puncture failure rates in landfill covers:

60mil LDPE: 0.02 failures/100 m²

60mil HDPE: 0.15 failures/100 m²

(HDPE’s rigidity increases crack propagation risks)

3.2 Enhanced Chemical Compatibility

LDPE’s non-polar structure resists a broader range of chemicals compared to PVC, which degrades under hydrocarbons or aromatic solvents.

Table 2: Chemical Resistance of 60mil LDPE Geomembrane

| Chemical | Concentration | Resistance |

Sulfuric Acid (H₂SO₄) | 98% | Excellent |

Sodium Hydroxide (NaOH) | 50% | Excellent |

Diesel Fuel | 100% | Excellent |

Methanol | 100% | Good |

Acetic Acid (20%) | 100% | Good |

3.3 Cost-Effective Longevity

While 60mil LDPE has a higher upfront cost than thinner membranes, its 50+ year design life reduces long-term replacement expenses.

Lifecycle Cost Analysis:

Material Cost: 0.80–1.20/ft² (60mil LDPE) vs. 1.50–2.00/ft² (60mil HDPE).

Maintenance Savings: LDPE’s flexibility minimizes seam failures, cutting repair costs by 30–40%.

4. Environmental and Durability Considerations

4.1 UV Stability and Aging Resistance

Carbon black dispersion ensures 1,500+ hours of UV exposure without embrittlement, extending outdoor lifespan to 50–70 years.

4.2 Low-Temperature Performance

Retains flexibility at -70°C (-94°F), preventing cracks in Arctic mining operations or alpine reservoirs.

4.3 Recyclability and Sustainability

LDPE is 100% recyclable, with post-consumer membranes repurposed into drainage boards or new geomembranes, aligning with circular economy goals.

5. Installation Best Practices

Proper installation maximizes performance:

Subgrade Preparation: Compact soil to 95% Standard Proctor Density to minimize settlement.

Welding: Use dual-track extrusion welders for seams, achieving 95% of base material strength.

Anchorage: Secure edges with concrete anchors or geotextile wraps to resist hydrostatic uplift.

Conclusion

The 60mil LDPE geomembrane sets the benchmark for heavy-duty containment, combining rugged durability with chemical resilience and installation efficiency. Its thick profile addresses the most demanding challenges in mining, waste management, and hydraulic engineering, ensuring environmental protection and asset longevity.