HDPE Liner for Tailing

1.High corrosion resistance: Resistant to acids, alkalis, salts and leachate from tailings, suitable for complex working conditions.

2.Strong anti-seepage performance: High density, stable molecular structure, effectively preventing harmful seepage liquid from leaking.

3.Anti-aging and durable: Add antioxidants and UV stabilizers, outdoor service life exceeds 50 years.

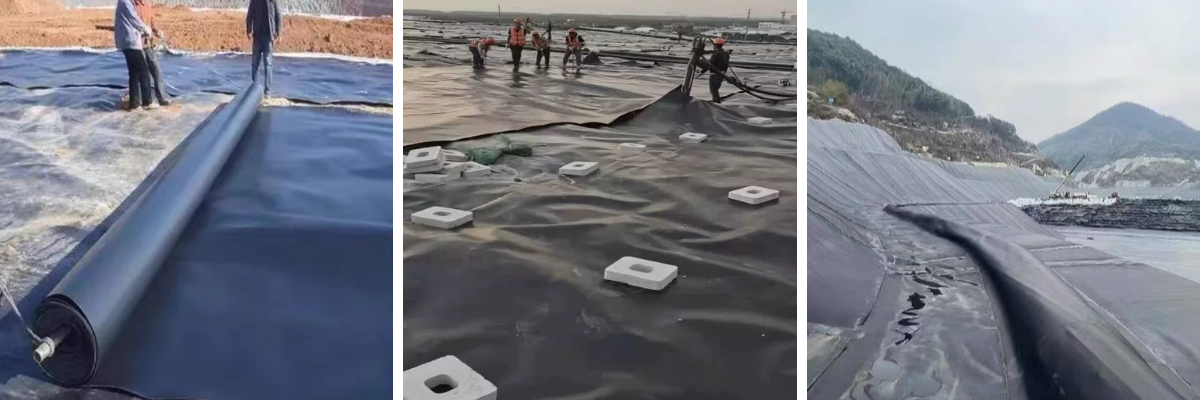

4.Convenient construction: Customizable production, mature welding technology, significantly shortens the construction period.

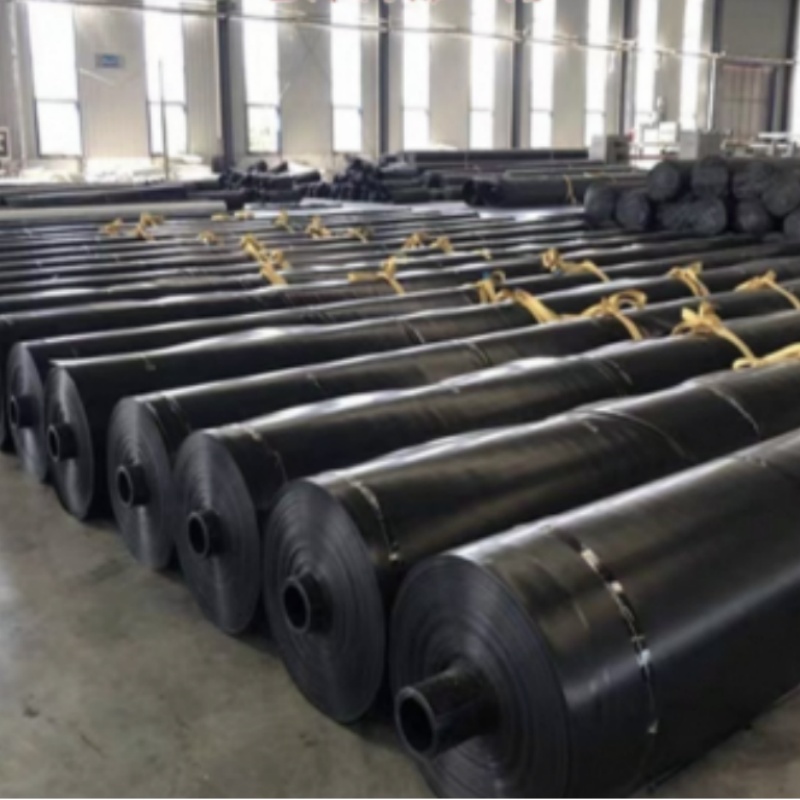

Product Introduction

HDPE tailings liner is a high-density polyethylene anti-seepage material specially designed for tailings treatment. It is made from high-quality HDPE raw materials through extrusion molding process, featuring a high-density molecular structure that can effectively prevent the leakage of tailings filtrate. It has strong corrosion resistance and can withstand the erosion of acids, alkalis, salts and chemical agents. Moreover, it contains anti-aging additives, with excellent resistance to ultraviolet rays and oxidation, and its outdoor service life can exceed 50 years. The construction is simple, supports customized dimensions, and forms a complete anti-seepage layer through hot-melt welding. It is widely used in anti-seepage projects such as tailings dams and slag heaps.

Product application

1.Mine tailings reservoirs: Used for seepage prevention at the bottom and slopes of the reservoir, to prevent the leaching of tailings from polluting the soil and groundwater, and to cover the storage scenarios of metal and non-metal mine tailings.

2.Metallurgical slag sites: Suitable for the stacking of waste residues generated from steel and non-ferrous metal smelting for seepage prevention, to resist the penetration of high-temperature slag materials and corrosive waste liquids.

3.Chemical tailings treatment: For the storage and disposal of toxic and harmful tailings from chemical production, to prevent the leakage of chemical agents from polluting the surrounding environment.

4.Environmental protection landfill sites: Extended to be applied in general industrial solid waste landfill sites, to assist in the collection of leachate and pollution control, in line with environmental protection standards.

Successful application cases of HDPE tailings lining

1. A tailings storage reservoir in an Indonesian gold mine: In 2019, an Indonesian client inquired about purchasing high-quality geotextile membranes for storing gold mine tailings. The supplier recommended 1.5-millimeter smooth HDPE geotextile membranes for the bottom of the tailings reservoir. These membranes have excellent water resistance and chemical resistance, can resist the erosion of heavy metals and residual beneficiation agents in the tailings, and effectively protect the local soil and environment.

2. A tailings treatment project of a mining company in the Philippines: A leading mining company in the area faced environmental challenges in tailings treatment. To meet strict environmental regulations and sustainable development requirements, HDPE geotextile membranes were adopted in the tailings accumulation area. They were laid at the bottom and side walls of the accumulation area, effectively isolating the penetration of harmful substances and ensuring the cleanliness and safety of groundwater.

3. A tailings treatment project in the Rocky Mountains region of the United States: The oil and gas field in this area generates a large amount of production water and reflux wastewater every year, requiring a safe, low-cost and efficient treatment method. The project uses HDPE-lined evaporation ponds to treat these wastewater. By taking advantage of the local arid climate, strong winds and abundant sunlight, as well as the heat absorption characteristics of the black HDPE lining, the wastewater is evaporated quickly, while protecting the surface and groundwater from pollution.

How to select the appropriate HDPE lining specifications and models for tailings treatment:

1. Project environmental parameters

Tailings characteristics:

If the tailings contain strong corrosive components (such as heavy metal ions, acid-base solutions), high-purity HDPE raw materials (such as GRS certified materials) should be selected. The thickness is recommended to be 1.5-2.0mm or more, to enhance the anti-permeation and corrosion resistance.

Tailings reservoir terrain is complex (such as steep slopes, stone bases), priority should be given to rough surface HDPE linings (surface roughness ≥ 250μm), to increase the friction coefficient and prevent sliding.

Climate conditions:

In hot regions (such as tropical areas), models with a UV-resistant additive content of ≥ 2.5% should be selected to delay aging; in cold regions (-20℃ or below), the material's brittleness temperature should be confirmed to be ≤ -70℃ to avoid low-temperature cracking.

2. Performance indicators matching

Physical properties:

Tensile strength at break ≥ 25MPa, elongation at break ≥ 700% (suitable for foundation settlement deformation);

Anti-puncture strength ≥ 500N (to deal with sharp particles in the tailings).

Leak prevention standard:

Permeability coefficient ≤ 1×10⁻¹³ cm/s (meeting the first-level standard of environmental protection landfill sites);

If involving drinking water source protection areas, it is recommended to undergo ASTM D5335 leakage detection certification.

3. Construction and compliance requirements

Size customization:

Priority should be given to wide-width products (such as 6-8 meters wide), to reduce the number of welds; length should be customized according to the reservoir size, to avoid excessive on-site splicing.

Compliance certification:

Domestic projects should comply with the "GB/T 17643-2021" geotextile membrane standard; export projects should meet ISO 13954 (tailings facility design specifications) or local environmental protection regulations (such as the US EPA standard).

4. Cost and after-sales balance

Cost-performance selection:

Temporary storage sites can choose 1.0-1.5mm smooth linings (lower cost); for permanent tailings reservoirs, 2.0mm rough surface linings (longer lifespan, higher safety) are recommended.

Supplier services:

Choose suppliers who provide on-site welding guidance and third-party test reports to ensure construction quality; after-sales should promise a 50-year warranty and regular aging detection services.

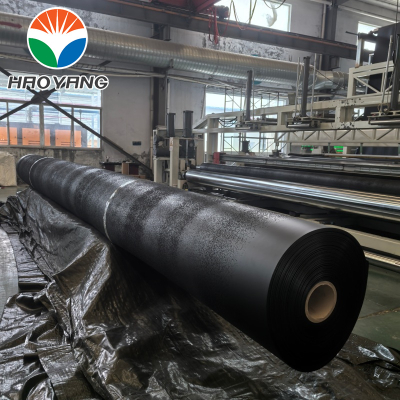

Why choose Haoyang Environment?

The HDPE tailings liner produced by Haoyang Environment has remarkable advantages. It uses high-quality raw resin and combines advanced three-layer co-extrusion technology to ensure excellent quality. The product specifications are diverse, with thickness ranging from 0.2 to 2mm and width from 6 to 10m, suitable for different tailings projects. Its permeability coefficient is as low as 1.0×10⁻¹³ cm/(cm²·s·Pa), with strong chemical stability, capable of resisting more than 80 kinds of strong acids and strong bases. It has excellent anti-aging performance and a service life of 50 - 70 years.