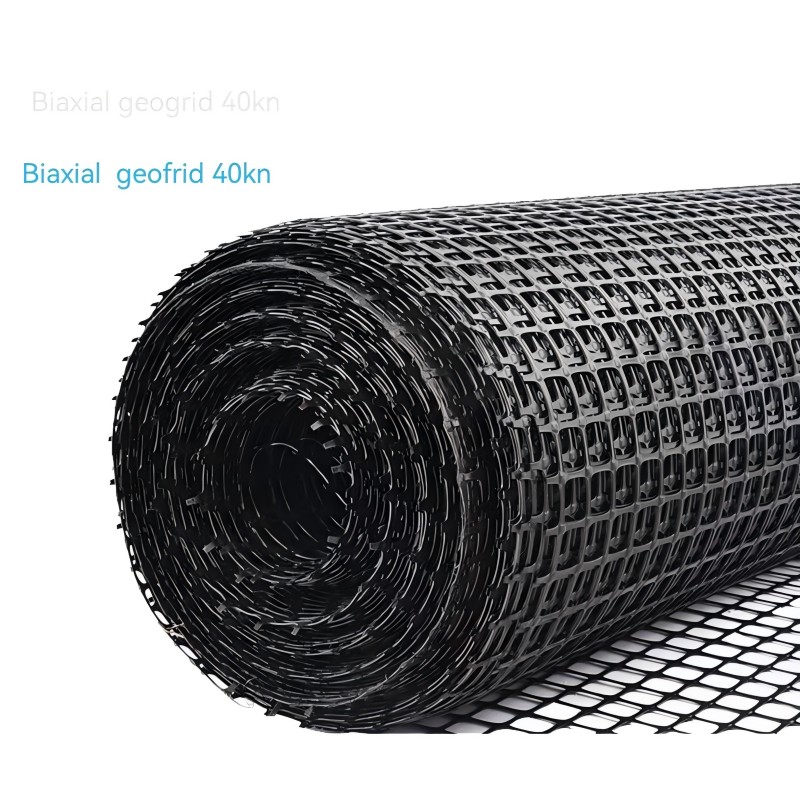

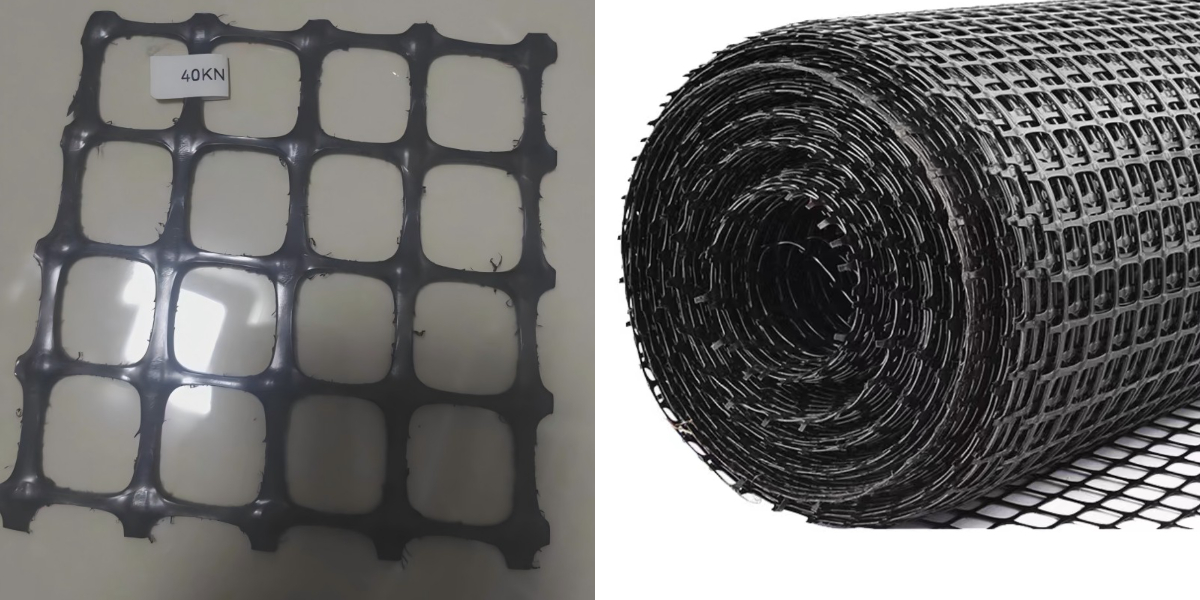

Biaxial Plastic Geogrids

Unidirectional Reinforcement: Optimized for high tensile strength in one direction - ideal for slopes, retaining walls and embankments.

Long-Term Load Performance: Maintains structural integrity under continuous stress with minimal creep deformation.

Mechanical Soil Locking: Unique grid design enhances load distribution and prevents soil displacement.

Harsh Environment Resistant: UV-stabilized HDPE/polyester construction withstands chemicals, moisture and extreme temperatures.

Construction Efficiency: Reduces material requirements and installation time while improving infrastructure longevity.

Product Introduction

Biaxial plastic geogrids are polymer-based grid structures designed with bidirectional (longitudinal and transverse) ribs to enhance soil stabilization and load distribution in civil engineering projects. Their unique geometry and material properties make them critical in reinforcing soil, reducing deformation, and improving infrastructure durability.

Product Specifications

Properties | Test Method | GM13 Test Value | Testing Frequency | ||||||

Thickness (min. ave.) | 0.75mm | 1mm | 1.25mm | 1.5mm | 2.0mm | 2.5mm | 3.0mm | (minimum) | |

nom. | nom. | nom. | nom. | nom. | nom. | nom. | Per roll | ||

lowest individual of 10 values | D5199 | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |

Formulated Density mg/l (min.) | D 1505/ D 792 | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 0.940 g/cc | 90,000kg |

Tensile Properties (1) (min. ave.) | D 6693 Type IV | 9,000kg | |||||||

. yield strength | 11kn/m | 15kn/m | 18kn/m | 22kn/m | 29kn/m | 37kn/m | 44kn/m | ||

. break strength | 20kn/m | 27kn/m | 33kn/m | 40kn/m | 53kn/m | 67kn/m | 80kn/m | ||

. yield elongation | 12% | 12% | 12% | 12% | 12% | 12% | 12% | ||

. break elongation | 700% | 700% | 700% | 700% | 700% | 700% | 700% | ||

Tear Resistance (min. ave.) | D 1004 | 93N | 125N | 156N | 187N | 249N | 311N | 374N | 20,000 kg |

Puncture Resistance (min. ave.) | D 4833 | 240N | 320N | 400N | 480N | 640N | 800N | 960N | 20,000 kg |

Stress Crack Resistance (2) | D5397 | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | 500 hr. | per GRI-GM10 |

(App.) | |||||||||

Carbon Black Content (range) | D 4218 (3) | 2.0-3.0% | 9,000kg | ||||||

Oxidative Induction Time (OIT) (min. ave.) (5) (a) Standard OIT | D 3895 D 5885 | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 100 min. | 90,000kg |

— or —(b) High Pressure OIT | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | 400 min. | ||

Oven Aging at 85°C (5), (6) | D 5721 D 3895 D 5885 | per each formulation | |||||||

(a) Standard OIT (min. ave.) - % retained after 90 days — or — | 55% | 55% | 55% | 55% | 55% | 55% | 55% | ||

(b) High Pressure OIT (min. ave.) - % retained after 90 days | 80% | 80% | 80% | 80% | 80% | 80% | 80% | ||

(a) Standard OIT (min. ave.) | D 3895 D 5885 | 50% | 50% | 50% | 50% | 50% | 50% | 50% | per each formulation |

— or — | |||||||||

(b) High Pressure OIT (min. ave.) - % retained after 1600 hrs (9) | |||||||||

Product Performance

1). High Tensile Strength and Balanced Load Distribution

Biaxial geogrids exhibit uniform tensile strength in both longitudinal and transverse directions due to their grid structure. This balanced strength allows them to distribute loads evenly across a wide area, preventing localized stress concentrations. For instance, studies on geogrids with reinforced nodes showed improved **ultimate pull-out resistance** compared to traditional designs, particularly under high normal stress conditions . The ribs interlock with soil particles, enhancing load transfer efficiency.

2). Superior Soil Stabilization

The interaction between geogrids and soil is critical. Laboratory pull-out tests demonstrated that the **interface shear strength** depends on soil grain size, moisture content, and transverse rib geometry. Larger soil particles and optimized rib spacing increase bearing resistance, while excessive moisture reduces friction but can be mitigated by design adjustments . This makes geogrids adaptable to diverse soil conditions.

3). Chemical and Environmental Resistance

Made from polymers like polypropylene or polyethylene, biaxial geogrids resist degradation from soil chemicals, moisture, and UV exposure. Research on materials like PEF (polyethylene furandicarboxylate) highlights their ability to maintain structural integrity under biaxial stretching, even developing strain-induced crystallization for enhanced rigidity and thermal stability .

4). Ease of Installation

Their lightweight and flexible design simplifies handling and reduces labor costs. For example, geogrids with **three-dimensional reinforcement nodes** improve installation efficiency while maintaining structural performance .

5). Durability Under Dynamic Loads

Experiments on materials subjected to freeze-thaw cycles and dynamic stress (e.g., seismic conditions) show that geogrid-reinforced systems maintain mechanical stability. This is vital for applications like roadbeds in cold climates or earthquake-prone areas.

Application Scenarios

1). Road and Railway Construction

Used to reinforce subgrades, reduce rutting, and extend pavement lifespan by distributing traffic loads. They are particularly effective in soft soil areas where differential settlement is a concern.

2). Slope and Embankment Stabilization

Prevents soil erosion and landslides by integrating with vegetation or retaining structures. The anisotropic shear strength of geogrid-soil interfaces ensures adaptability to complex stress directions .

3). Retaining Walls

Enhances the structural integrity of mechanically stabilized earth (MSE) walls by providing lateral support and reducing earth pressure.

4). Foundation Engineering

Improves bearing capacity for structures built on weak soils, such as industrial platforms or building foundations.

5). Environmental and Hydraulic Projects

Applied in landfill liners, coastal protection, and riverbank reinforcement to withstand hydraulic forces and chemical exposure.

Why choose Haoyang?

1. Imported Raw Materials

High-quality raw materials sourced from **Saudi Arabia** ensure superior product performance and consistency from the source.

2. World-Leading 10m Blown Film Production Line

Equipped with advanced five-layer co-extrusion technology, capable of producing both smooth and textured geomembranes with a maximum width of 10 meters.

3. Direct-from-Factory Production

As a manufacturer, we guarantee premium quality while offering the most competitive prices by eliminating middlemen.

4. Fast Delivery

High daily output of 70 tons ensures timely delivery to meet urgent project timelines.

5. One-Stop Solution

Beyond manufacturing and sales, we provide **professional project construction teams** to deliver end-to-end solutions for seamless project execution.