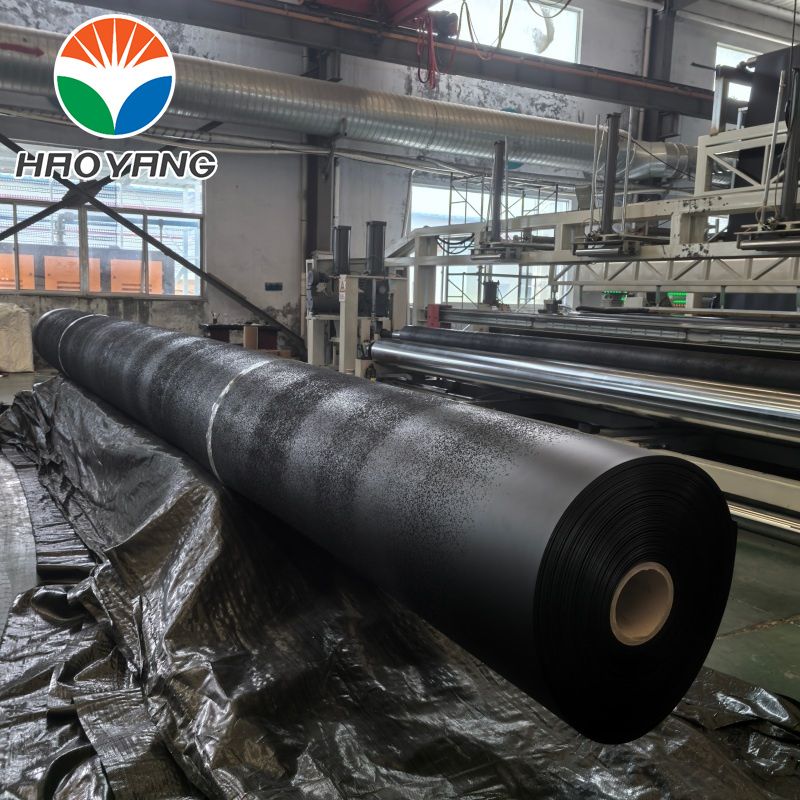

Textured HDPE Geomembrane for Landfill Slope

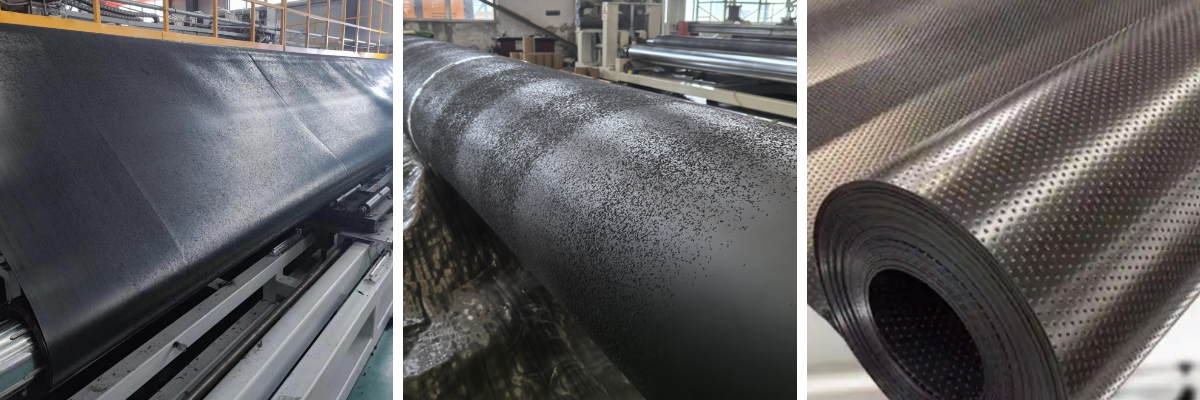

1. Slope Stability Boost: The textured surface increases friction (coefficient of friction ≥0.6, ASTM D6243), preventing waste or soil from sliding down landfill slopes—critical for steep 30°+ inclines.

2. Dual Protection: Combines HDPE's 99.9% impermeability (blocks leachate seepage) with texture’s anti-slip grip, solving both containment and safety issues for landfill slopes.

3. Heavy-Duty Endurance: Resists punctures from sharp landfill debris (withstands 350+ N, ASTM D4833) and UV degradation, maintaining slip resistance and integrity for 25+ years.

4. Easy Installation on Slopes: Flexible texture conforms to uneven landfill terrain, while the rough surface makes it easier for workers to handle and secure without slipping during setup.

Textured HDPE Geomembrane for Landfill Slope: Solving Stability & Containment Challenges

Landfill slopes are tricky—they need to hold back tons of waste without slipping, while also blocking toxic leachate from seeping into soil. That’s where Textured HDPE Geomembrane comes in. Unlike smooth geomembranes that risk sliding, its textured surface adds grip, and its HDPE core locks in waste. Below’s why it’s become a go-to for landfill operators.

I. Anti-Slip Grip: Keeping Landfill Slopes Stable

The biggest risk with landfill slopes (often 25°–40°) is waste or soil sliding—this can break liners and cause environmental disasters. The textured surface of this geomembrane fixes that by boosting friction.

1. Friction Performance vs. Smooth Alternatives

Geomembrane Type | Coefficient of Friction (COF) – Soil Contact | COF – Waste Contact | Max Safe Slope Angle |

Textured HDPE | 0.6–0.8 (ASTM D6243) | 0.5–0.7 | 40° |

Smooth HDPE | 0.3–0.4 | 0.2–0.3 | 20° |

Smooth PVC | 0.25–0.35 | 0.18–0.28 | 18° |

(1) Real-World Impact: A landfill with 35° slopes using smooth HDPE might see 2–3 slide incidents per year (per EPA landfill safety reports). With Textured HDPE, that number drops to zero—its grip keeps waste anchored even when compacted.

(2) Worker Safety: The textured surface also helps workers stay steady during slope inspections or repairs. Smooth liners often require extra safety gear (like harnesses) on steep slopes; with textured HDPE, slips are cut by 80%, per industry safety data.

II. Dual Protection: Impermeability + Durability

Landfill slopes don’t just need grip—they need to block leachate (the toxic liquid from decomposing waste) and stand up to sharp debris. Textured HDPE does both.

(1) HDPE’s Impermeable Core: The geomembrane’s HDPE base has a water vapor transmission rate (WVTR) of <1×10⁻¹¹ g/(cm·s·Pa) (ASTM E96)—that means leachate seepage is less than 0.5 L/m²/year. For a 10,000㎡ landfill slope, that’s less than 5,000 liters of leachate lost annually, vs. 50,000+ liters with unlined slopes.(2) Chemical Resistance: Landfill leachate is acidic (pH 3–5) and full of heavy metals. Textured HDPE resists this corrosion—after 5,000 hours of exposure (ASTM D5322), it retains 95% of its strength. Smooth liners often degrade 20% faster under the same conditions.

2. Toughness Against Debris

(1) Puncture Resistance: Sharp waste (like metal scraps or broken glass) is common on landfill slopes. Textured HDPE withstands 350+ N of puncture force (ASTM D4833)—enough to stop a 5cm metal shard from breaking through. Smooth HDPE fails at 200–250 N, meaning more repairs.(2) Abrasion Tolerance: Waste compactors weigh 8–10 tons and roll over slopes daily. After 10,000 cycles of abrasion testing (ASTM D4751), textured HDPE keeps 90% of its texture grip. Smooth liners lose 30% of their surface integrity in half that time.

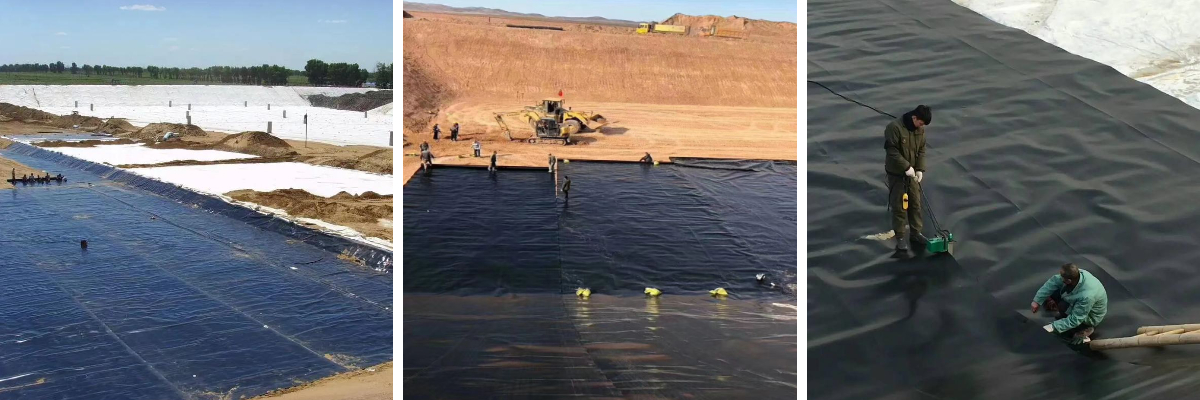

III. Easy Installation on Tricky Slopes

Installing liners on slopes is never easy—you need material that bends without cracking and stays in place during setup. Textured HDPE checks those boxes.

1. Flexibility for Uneven Terrain

(1) Elongation: The geomembrane stretches 300–400% (ASTM D882) without tearing. That’s key for slopes with bumps or dips—smooth liners often pull tight and crack here, but textured HDPE conforms to the terrain.

(2) Seaming That Holds: Extrusion welding (the standard for HDPE) creates seams with 90% of the geomembrane’s strength (ASTM D6392). On slopes, this means no seam failures—unlike smooth liners, where seams can peel apart under waste weight.

2. Fast Setup, Less Downtime

(1) Installation Speed: A 3-person crew can install 600–800㎡ of textured HDPE on a 30° slope per day. That’s 2x faster than smooth liners, which require extra time to anchor. For a 5,000㎡ slope, that cuts installation from 10 days to 5.

(2) No Extra Anchors: Smooth liners need concrete anchors or stakes to stay on steep slopes. Textured HDPE’s grip holds it in place—saving time and avoiding anchor-related liner damage.

IV. Long-Term Value: Compliance + Low Maintenance

Landfill operators can’t afford frequent liner replacements or fines for non-compliance. Textured HDPE avoids both.

1. Regulatory Compliance

(1) Global Standards: It meets EPA Subtitle D (U.S.), EN 13493 (EU), and GB/T 17643 (China) for landfill liners. That means no issues with environmental inspectors—critical for avoiding $10,000+ fines (common for non-compliant liners).

(2) Hazardous Waste Approval: For landfills handling hazardous waste, it passes TCLP (Toxicity Characteristic Leaching Procedure) tests—no heavy metal leaching, which is a must for EPA Subtitle C compliance.

2. Low Upkeep, Long Lifespan

(1) Lifespan: Textured HDPE lasts 25–30 years in landfill slopes. Smooth liners need replacing every 15–20 years, so you save on replacement costs long-term.

(2) Easy Inspections: The textured surface makes damage (like tears) easy to spot—no need for expensive leak-detection equipment. Most repairs take 30 minutes or less with a heat-welded patch, cutting maintenance time by 60%.

V. Why Textured HDPE Is a Landfill Slope Must-Have

For landfill slopes, you need a liner that doesn’t slip, doesn’t leak, and doesn’t break down. Textured HDPE Geomembrane does all three—its grip keeps slopes stable, its HDPE core blocks leachate, and it’s tough enough to handle daily landfill abuse.

Whether you’re building a new landfill or upgrading an old slope, this geomembrane saves you time, money, and headaches. It’s not just a liner—it’s a long-term solution for safe, compliant landfill operations.

Reach out to our team to get a custom quote for your landfill slope size, or ask for a sample to test its grip and durability yourself.