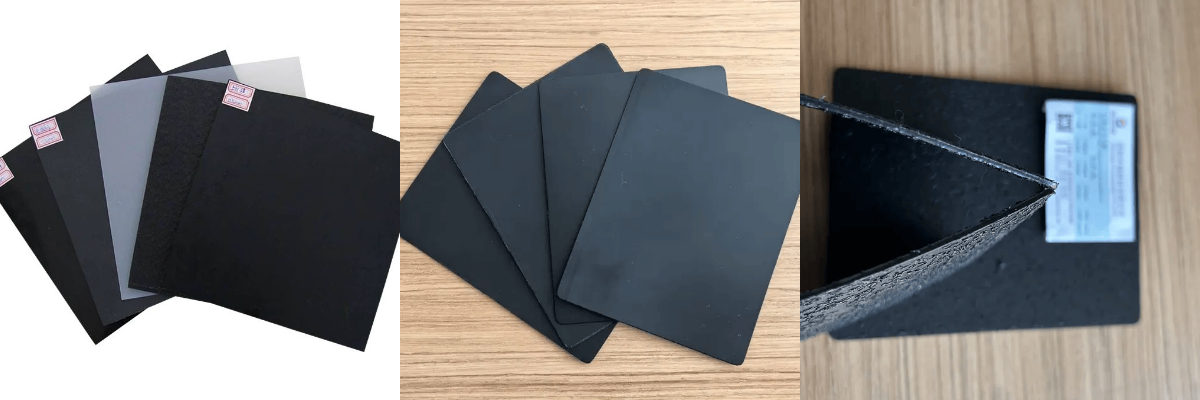

0.75mm HDPE Geomembrane Fish Tank Liner

1. Material safety and durability: The 0.75mm HDPE material is corrosion-resistant, anti-aging, and does not release harmful substances, ensuring the safety of fish survival.

2. Excellent water-proof performance: The high-density polyethylene structure is tight, with excellent water-proofing performance, preventing water leakage.

3. Good flexibility and adaptability: The material is flexible and easy to shape, suitable for different-shaped fish tanks, and installation is convenient.

4. Easy cleaning and maintenance: The surface is smooth and does not easily accumulate dirt, and daily cleaning is simple with just wiping.

0.75mm HDPE Geomembrane: The Multi-Faceted Legend of the Fish Pond Liner Guardian

Chapter 1: Introduction to Geomembranes

Geomembranes, as a key material widely used in civil engineering and environmental engineering, are mainly made of polymer materials. HDPE geomembranes, which are waterproof and barrier-type materials, are produced using high-density polyethylene resin as the raw material, with a density of 0.94g/cm3 or above. They possess excellent resistance to environmental stress cracking, cold resistance, aging resistance, and corrosion resistance. Their operating temperature range is from -60℃ to +60℃, and their service life can last up to 50 years. They have waterproof, anti-permeation, and corrosion-resistant properties, and are widely used in landfills, wastewater treatment, dams, tunnels, airport runways, building foundations, and many other fields.

Among them, 0.75mm HDPE geomembrane has significant advantages in fishpond applications. It can not only effectively prevent fishpond leakage, maintain a stable water level, reduce water resource waste, but also prevent harmful substances in the soil from seeping into the fishpond, ensuring water quality, providing a healthy growth environment for fish, and also prevent the agricultural wastewater in the fishpond from polluting the surrounding soil and groundwater, which is of great significance for environmental protection.

Chapter 2: Physical and Chemical Properties

(1) Physical Properties

The 0.75mm HDPE geomembrane possesses excellent physical properties

| physical properties | index |

| Tensile strength (longitudinal/transverse) | ≥25MPa |

| elongation at break | ≥700% |

| Right-angle tear strength | ≥110N/mm |

| anti-ultraviolet | Excellent. Anti-uv additives are added to slow down aging |

| Low-temperature embrittlement resistance | Operating temperature range: -70 ℃ to 110℃ |

(2) Chemical Properties

The 0.75mm HDPE geotextile membrane exhibits outstanding chemical stability. It can resist corrosion from more than 80 kinds of chemical substances such as strong acids, alkalis, and oils, making it an ideal choice for high-corrosion environments in industries like chemical and petrochemical.

Chapter 3: Application Areas

The 0.75mm HDPE geotextile membrane, with its outstanding performance, plays a crucial role in various fields. In the environmental protection and sanitation sector, it is used as a waterproof layer in projects such as landfill sites and sewage treatment plants, effectively preventing the leakage of waste water and landfill leachate, avoiding soil and groundwater pollution, preventing the spread of harmful substances, and protecting the surrounding environment.

1. In water conservancy projects: Its use is indispensable for flood control, leakage prevention, and water channel waterproofing in rivers, lakes, and reservoirs. It can reduce water leakage losses, ensure the stability of dams and the normal operation of water conservancy facilities, and guarantee the stability of agricultural irrigation and urban water supply.

2. In municipal engineering: 0.75mm HDPE geotextile membranes are often used for waterproofing and moisture-proofing in subway construction and underground projects of buildings. In subway construction, it can prevent groundwater from seeping into the tunnel, ensuring the safety of subway operation and the durability of facilities; in underground projects of buildings, it can prevent the basement from getting damp, protecting the building structure.

3. In agriculture and aquaculture: This geotextile membrane is used in reservoirs and fish ponds, effectively maintaining water levels, reducing water evaporation and leakage, and providing a stable water source for crop irrigation and aquaculture. In fish ponds, it can prevent the leakage of breeding water from polluting the surrounding soil and prevent harmful substances from entering the fish pond, creating a healthy growth environment for fish and promoting the development of the aquaculture industry.

Chapter 4: Factors Affecting Price

The price of 0.75mm HDPE geomembrane is not constant but is influenced by multiple factors.

1. Raw material cost is the primary factor. The HDPE geomembrane is mainly made of high-density polyethylene (HDPE) resin. The fluctuation in the price of HDPE directly affects the production cost of the geotextile membrane.

2. Production process and technical level are also crucial. Advanced production processes and high-end technical equipment can produce geotextile membranes with better performance, but this will increase production costs and thereby raise the product price.

3. Market supply and demand have a direct impact on the price.

4. Brand factors cannot be ignored. Well-known brands, with good reputation, reliable quality and excellent after-sales service, often gain higher pricing power in the market.

Chapter 5: Global Application Cases

In practical applications, 0.75mm HDPE geotextile membranes have demonstrated outstanding performance and significant effects in various projects across multiple countries.

1. In a landfill site in the United States, to effectively prevent the contamination of groundwater by landfill leachate, 0.75mm HDPE geotextile membranes were selected as the anti-seepage layer. This landfill site processes a large amount of domestic and industrial waste daily, and the composition of the landfill leachate is complex, posing a great threat to the environment. After laying the geotextile membrane, the problem of leachate seepage was effectively controlled, and the surrounding soil and groundwater were not contaminated. The environmental protection effect was remarkable.

2. In a reservoir in China, due to complex geological conditions and severe leakage problems, which affected the reservoir's water storage capacity and irrigation functions. After using 0.75mm HDPE geotextile membranes for anti-seepage treatment, the leakage volume of the reservoir was significantly reduced, and the water storage capacity increased significantly. This ensured the irrigation water supply for surrounding farmlands, promoted local agriculture development, and also improved the economic and social benefits of the reservoir.

3. In a large-scale fish farm in Thailand, when building fish ponds, 0.75mm HDPE geotextile membranes were used. The breeding water in the fish ponds was effectively maintained, avoiding contamination of the surrounding soil by leakage, and also preventing harmful substances from entering the fish ponds, providing a healthy and stable growth environment for fish. The fish yield and quality were improved, and the economic benefits and social benefits of the farm significantly increased.

Chapter 6: Reflection and Outlook

(1) Analysis of Deficiencies

Although the 0.75mm HDPE geotextile membrane has demonstrated outstanding performance in various fields, it also has some shortcomings. From an ecological perspective, although its waterproofing performance is excellent, it blocks the exchange and mutual regulation between water bodies and groundwater, making it limited in application in water conservancy projects with high ecological requirements, such as the construction of ecological rivers.

The uneven quality of geomembranes on the market is also a major problem. Some manufacturers, in an attempt to reduce costs, use inferior raw materials or outdated production processes, resulting in products that do not meet physical performance standards. These quality issues not only affect the normal use of geotextile membranes but also may lead to serious consequences such as leakage and structural damage, increasing the maintenance costs and environmental risks of the project.

(2) Future Prospects

Looking ahead, with the continuous advancement of technology, the 0.75mm HDPE geotextile membrane is expected to make greater breakthroughs in performance and environmental protection. In terms of performance improvement, through the development of new material formulas and the improvement of production processes, it is expected to further enhance its strength, weather resistance, and resistance to chemical corrosion, enabling it to be used stably in more complex and harsh environments. In terms of environmental protection, developing recyclable HDPE geotextile membranes to reduce environmental pressure and achieve resource recycling will become one of the future development directions. More environmentally friendly production processes may also be adopted to reduce energy consumption and pollutant emissions during the production process.

It is very necessary to increase investment in the research and development of HDPE geotextile membranes. Research institutions and enterprises should strengthen cooperation to jointly explore new technologies and new materials, promoting technological innovation in HDPE geotextile membranes. It is believed that with the joint efforts of all parties, the 0.75mm HDPE geotextile membrane will be continuously improved and play a greater role in more fields, contributing more to global infrastructure construction, environmental protection, and sustainable development.