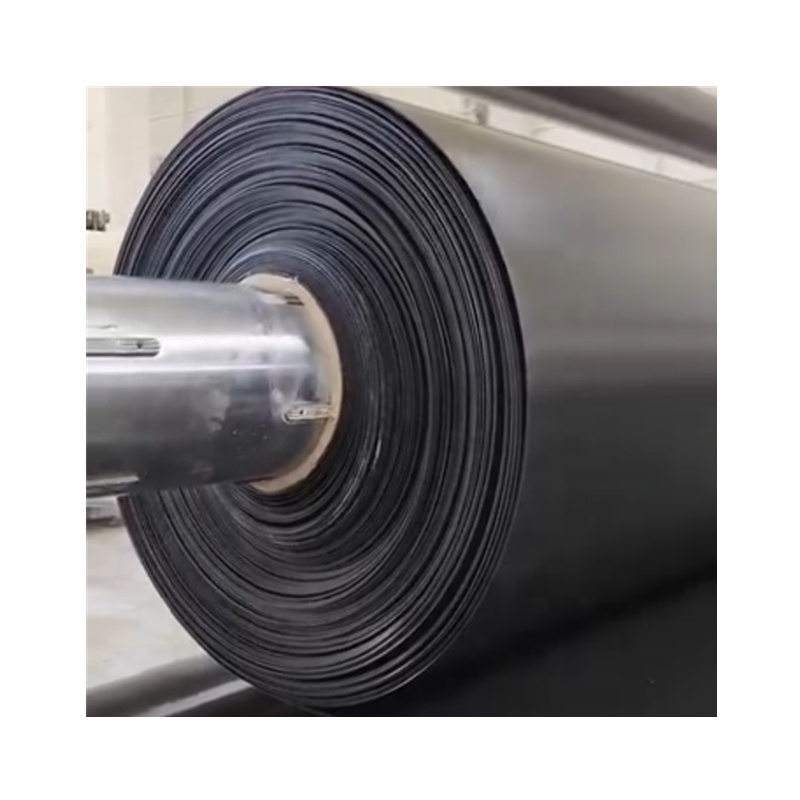

Waterproof 0.75mm HDPE Geomembrane

Superior Load-Bearing Capacity: Resists deformation under heavy mechanical stress.

Broad Chemical Compatibility: Withstands aggressive industrial and mining chemicals.

Multi-Decade Lifespan: Delivers reliable performance in permanent infrastructure applications.

Waterproof 0.75mm HDPE Geomembrane: Engineering Excellence for Demanding Environments

Introduction

High-Density Polyethylene (HDPE) geomembranes are critical for modern infrastructure projects requiring reliable containment and waterproofing. The 0.75mm HDPE variant represents an advancement in material science, offering enhanced durability and adaptability for applications where thinner membranes may fall short. This article examines the technical attributes, environmental resilience, and practical benefits of this geomembrane, supported by empirical data and real-world use cases.

Technical Specifications: Precision and Performance

The 0.75mm HDPE geomembrane is engineered to exceed industry standards for impermeability and mechanical strength. Its design prioritizes longevity in high-stress environments, from industrial wastewater ponds to mining leach pads.

Table 1: Core Physical and Mechanical Properties

| Property | Specification | Test Method |

Thickness | 0.75 mm ± 5% | ASTM D5199 |

Density | 0.940–0.960 g/cm³ | ASTM D1505 |

Tensile Strength (MD/TD) | ≥ 35 MPa | ASTM D6693 |

Elongation at Break | ≥ 550% | ASTM D6693 |

Carbon Black Content | 2.5–3.5% | ASTM D1603 |

Puncture Resistance | ≥ 600 N | ASTM D4833 |

UV Resistance | > 2500 hours | ASTM D4355 |

Compared to thinner membranes, the 0.75mm variant demonstrates superior puncture resistance and tensile strength, making it ideal for projects with sharp substrates or heavy loads.

Environmental and Chemical Resistance

This geomembrane excels in hostile environments, resisting degradation from aggressive chemicals, UV radiation, and temperature extremes. Its stability in acidic, alkaline, and organic solvent-rich settings ensures long-term performance.

Table 2: Chemical Resistance Performance

| Chemical Type | Exposure Duration | Performance Impact |

30% Hydrochloric Acid | 30 days | No surface erosion |

20% Sodium Hydroxide | 30 days | Minimal swelling (<2%) |

Toluene | 7 days | No blistering or softening |

Ammonia Solution (pH 11) | 14 days | No discoloration or cracking |

This resilience positions the material as a top choice for chemical processing plants, oil and gas containment, and hazardous waste management.

Diverse Applications in Modern Engineering

The 0.75mm HDPE geomembrane serves multiple sectors with precision:

Mining and Metallurgy: Contains cyanide-laced tailings and acidic runoff.

Industrial Wastewater: Lines treatment ponds for steel, paper, and textile industries.

Transportation Infrastructure: Waterproofs tunnels, bridges, and retaining walls.

Aquaculture: Seals reservoirs and fish farms exposed to saline water.

A case study in Southeast Asia highlighted its use in a copper mine’s tailings pond, where it maintained integrity despite abrasive slurries and temperature fluctuations. In Scandinavia, a highway tunnel project utilized the material to prevent groundwater infiltration, achieving zero leakage over three years.

Installation Best Practices

Proper installation ensures optimal performance:

Substrate Preparation: Remove debris, level surfaces, and apply protective geotextiles.

Seaming Techniques: Use dual-track thermal welding for airtight joints.

Quality Assurance: Perform non-destructive testing (e.g., vacuum box tests) to detect defects.

Routine inspections every six months are recommended to address minor damages promptly.

Advantages of 0.75mm HDPE Geomembrane

Enhanced Structural Integrity: Withstands heavy loads and sharp objects, reducing repair frequency.

Long-Term Environmental Stability: Maintains performance in extreme pH and temperature conditions.

Versatile Adaptability: Suitable for both temporary and permanent installations across industries.

Conclusion

The 0.75mm HDPE geomembrane emerges as a robust solution for projects demanding superior protection and longevity. Its balance of mechanical strength, chemical resistance, and adaptability makes it indispensable in sectors like mining, infrastructure, and environmental engineering. As global standards for sustainability and safety tighten, this material will continue to play a pivotal role in building resilient, eco-conscious systems.