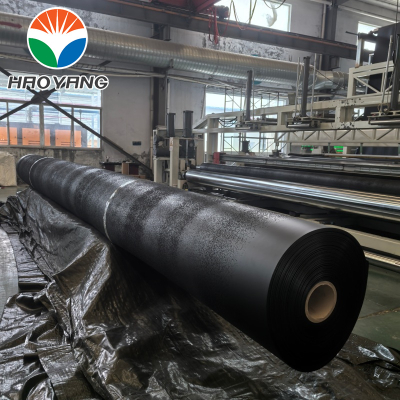

Waterproof 0.5mm HDPE Geomembrane

Exceptional Durability: Withstands harsh chemicals, extreme temperatures, and mechanical stress.

Cost-Effective Performance: Delivers premium protection at a lower thickness, reducing material expenses.

Ease of Installation: High flexibility simplifies deployment on complex substrates, minimizing labor and time.

Waterproof 0.5mm HDPE Geomembrane: A Comprehensive Analysis of Performance and Applications

Introduction

High-Density Polyethylene (HDPE) geomembranes have become a cornerstone of modern engineering projects requiring impermeable barriers. Among these, the 0.5mm HDPE geomembrane stands out for its balance of flexibility, durability, and cost-effectiveness. This article explores the technical specifications, applications, and advantages of this material, supported by empirical data and real-world case studies.

Technical Specifications

The 0.5mm HDPE geomembrane is engineered to meet stringent international standards for waterproofing and environmental protection. Its physical and mechanical properties are critical to its performance in diverse conditions.

Table 1: Physical and Mechanical Properties

| Property | Specification | Test Method |

Thickness | 0.5 mm ± 5% | ASTM D5199 |

Density | 0.935–0.965 g/cm³ | ASTM D1505 |

Tensile Strength (MD/TD) | ≥ 27 MPa | ASTM D6693 |

Elongation at Break | ≥ 600% | ASTM D6693 |

Carbon Black Content | 2–3% | ASTM D1603 |

UV Resistance | > 1800 hours | ASTM D4355 |

Puncture Resistance | ≥ 400 N | ASTM D4833 |

These parameters ensure the material withstands mechanical stress, environmental degradation, and chemical exposure. The high elongation capacity (≥600%) allows it to conform to uneven substrates, minimizing the risk of tears during installation.

Environmental and Chemical Resistance

HDPE geomembranes are renowned for their resistance to acids, bases, and organic solvents. The 0.5mm variant maintains stability in extreme pH environments (2–12) and temperatures ranging from -70°C to 80°C.

Table 2: Chemical Resistance Performance

| Chemical Type | Exposure Duration | Performance Impact |

50% Sulfuric Acid (pH 1) | 30 days | No degradation |

10% Sodium Hydroxide | 30 days | No swelling or cracking |

Diesel Fuel | 7 days | Minor surface discoloration |

Methanol | 7 days | No structural changes |

This resilience makes the material ideal for applications in mining, wastewater management, and agricultural containment.

Applications in Engineering Projects

The 0.5mm HDPE geomembrane is deployed across multiple sectors:

Landfill Liners: Prevents leachate contamination of soil and groundwater.

Hydraulic Engineering: Used in canals, reservoirs, and dams for seepage control.

Mining Operations: Contains toxic tailings and process chemicals.

Agriculture: Lines irrigation ponds and aquaculture systems.

A case study in Europe demonstrated its efficacy in a wastewater treatment plant, where it reduced seepage rates by 98% over five years. Similarly, in arid regions, agricultural projects report a 40% increase in water retention efficiency.

Installation and Maintenance Considerations

Proper installation is critical to maximizing performance. Key steps include:

Substrate Preparation: Ensure a smooth, debris-free surface.

Seaming Techniques: Use thermal fusion or extrusion welding for airtight joints.

Quality Control: Conduct air channel tests and electrical leak surveys.

Maintenance is minimal, requiring periodic inspections for physical damage or UV degradation. Repairs can be performed using patch kits compatible with HDPE.

Advantages of 0.5mm HDPE Geomembrane

Durability: Resists cracking, puncturing, and chemical degradation, ensuring long-term service life (20–30 years).

Cost Efficiency: Lower material and installation costs compared to thicker alternatives without compromising performance.

Flexibility: Adapts to irregular terrain, reducing installation complexity and time.

Conclusion

The 0.5mm HDPE geomembrane represents a versatile, reliable solution for waterproofing and containment challenges. Its technical robustness, environmental resistance, and economic viability make it a preferred choice for engineers and project managers worldwide. As environmental regulations tighten, this material will play an increasingly vital role in sustainable infrastructure development.