40mil HDPE Dam Liner

1.Excellent Waterproofing – Provides superior anti-seepage performance for dam and pond lining.

2.High Tensile Strength – Withstands pressure and ground movement without cracking.

3.UV Resistant – Long-lasting protection against sunlight degradation.

4.Chemical Resistant – Durable in harsh environments with acids, alkalis, and waste.

5.Flexible and Easy to Install – Adapts to uneven surfaces and simplifies on-site handling.

6.Environmentally Friendly – Made from 100% virgin HDPE, safe for water and soil.

40mil HDPE Dam Liner

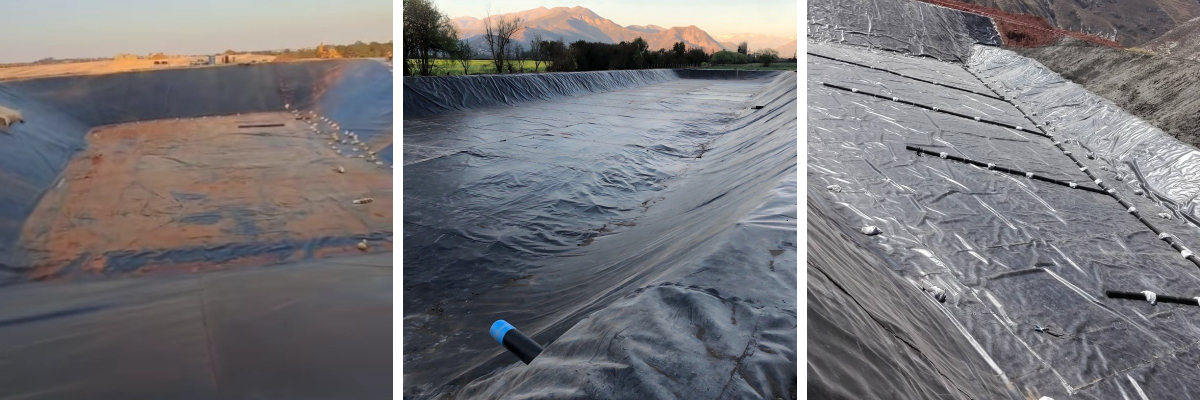

In the construction and maintenance of water containment systems, the right choice of lining material can make the difference between long-term performance and costly failures. The 40mil HDPE Dam Liner is a premium-grade geomembrane designed for demanding applications where durability, impermeability, and environmental safety are crucial. Manufactured from high-density polyethylene (HDPE), this liner is widely used in dam construction, ponds, reservoirs, landfills, and industrial water treatment projects due to its outstanding physical and chemical properties.

What Is a 40mil HDPE Dam Liner?

The term "40mil" refers to the thickness of the liner, equivalent to 1.0mm (1 mil = 0.0254 mm). This thickness strikes a balance between flexibility and strength, making it ideal for medium to large-scale water retention projects. The HDPE material is known for its excellent chemical resistance, UV stability, and mechanical strength, ensuring reliable performance in both exposed and buried conditions.

Key Advantages of 40mil HDPE Dam Liner

1. Superior Anti-Seepage Performance

Water leakage is a critical concern in dam and pond applications. The 40mil HDPE liner offers excellent impermeability, preventing seepage and preserving water resources. Its low permeability rate ensures long-term containment, making it suitable for applications where water loss can result in environmental or financial damage.

2. High Strength and Tear Resistance

Thanks to its molecular density and high tensile strength, HDPE performs well under tension and pressure. The 40mil thickness provides strong mechanical protection against punctures, stress cracking, and ground movement. This makes it especially reliable in regions with seismic activity or shifting soil conditions.

3. Outstanding UV and Weather Resistance

Exposure to sunlight and harsh weather conditions can degrade many types of liners over time. The 40mil HDPE liner is formulated with carbon black and UV stabilizers, offering excellent resistance to photodegradation. Whether the liner is installed above ground or partially exposed, it retains its integrity for years without becoming brittle or cracking.

4. Chemical and Biological Resistance

In many dam and reservoir projects, water may contain chemicals, heavy metals, or organic compounds. The 40mil HDPE liner resists degradation from a wide range of chemicals, acids, alkalis, and microbial attacks, ensuring that the liner remains functional even in challenging environments such as mining, industrial waste treatment, or agricultural runoff containment.

5. Cost-Effective and Low Maintenance

One of the reasons engineers and project managers choose the 40mil HDPE liner is its excellent life cycle cost. It has a service life of over 20 years when properly installed and maintained. The installation is straightforward, and once in place, it requires minimal maintenance, reducing long-term operating costs.

6. Eco-Friendly and Safe

Made from 100% virgin HDPE material, the liner is safe for use in drinking water reservoirs, aquaculture ponds, and other environmentally sensitive projects. It does not leach harmful substances into the soil or water, helping protect local ecosystems and comply with international environmental standards.

Applications of 40mil HDPE Dam Liner

Due to its versatility, the 40mil HDPE liner is used in a wide range of water-related and environmental protection projects:

1.Irrigation and farm dams

2.Water reservoirs and storage basins

3.Municipal and industrial wastewater treatment plants

4.Aquaculture ponds and fish farms

5.Landfill base and capping systems

6.Mining tailings dams and heap leach pads

Its proven performance across various industries has made it a standard material in both public and private infrastructure projects.

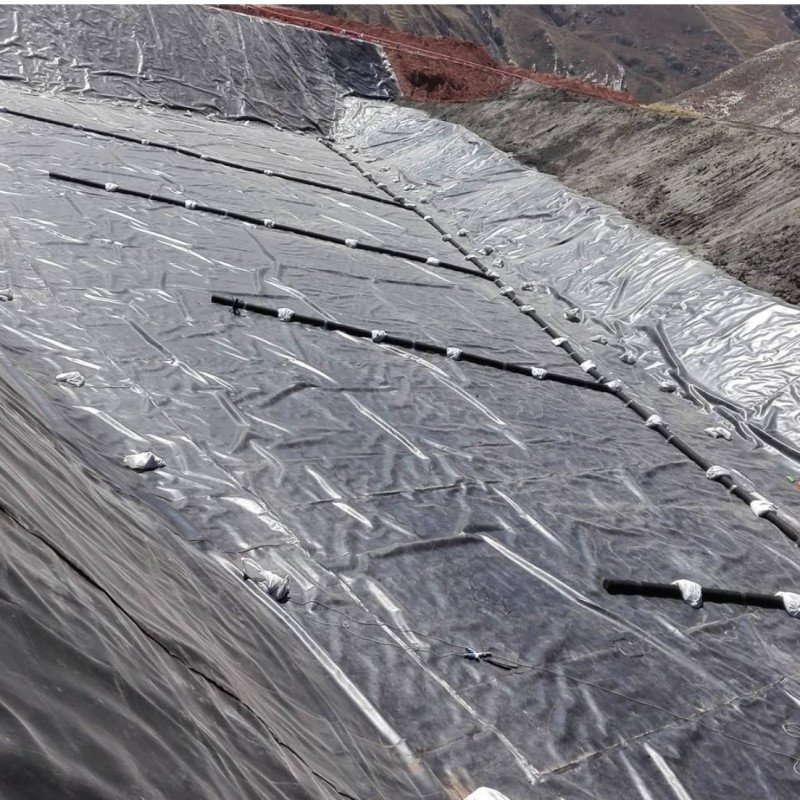

Installation and Welding Services

To ensure the liner performs optimally, professional installation is essential. Our company offers complete support, including on-site welding and seam testing services. Using advanced fusion welding machines, our certified technicians ensure that all joints are securely bonded, eliminating the risk of leaks.

Seams are tested using air pressure and vacuum methods to meet quality assurance standards. Detailed installation guidelines are provided, and our technical team is available for remote or on-site consultation.

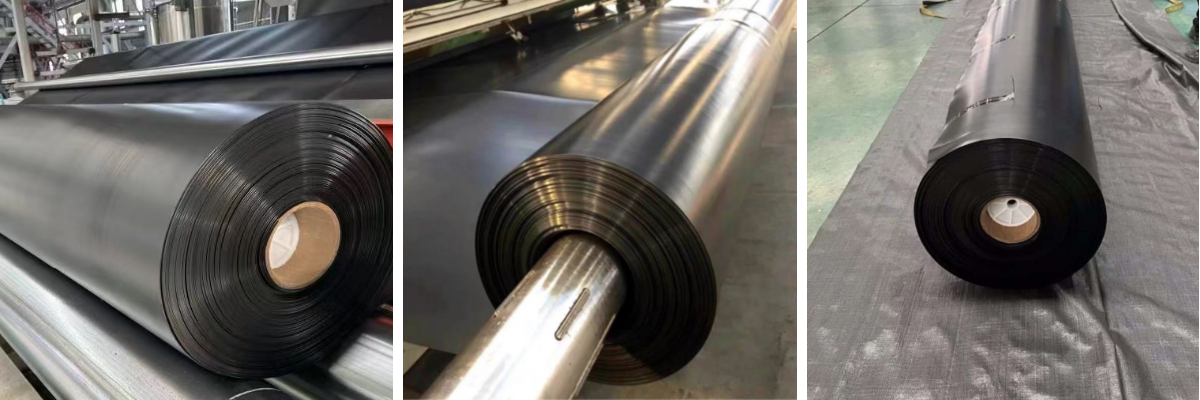

Product Specifications

Material: High-Density Polyethylene (HDPE)

Thickness: 40mil (1.0mm)

Roll Width: Customizable, standard 5.8m–8m

Roll Length: Customizable based on project needs

Color: Black (other colors available upon request)

Surface: Smooth or textured finish available

Certification: ISO 9001, ISO 14001, CE, GRI-GM13 compliance

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Why Choose Us as Your HDPE Dam Liner Supplier?

As a leading manufacturer and direct source factory, we are committed to delivering high-quality geomembrane solutions that meet international standards. With over 15 years of experience in geomembrane production and installation, we have supplied materials for hundreds of dam and water management projects both in China and overseas.

What We Offer:

100% Virgin HDPE Material

Advanced Blow Film Technology

Strict Quality Control System

Global Export Experience

Professional Technical Support

Fast Delivery and Custom Sizes

Our production lines are equipped with automated quality inspection and uniform thickness control to ensure each roll of liner meets project requirements. We understand the critical nature of water containment and are dedicated to helping our clients achieve long-term, leak-free results.

Request a Quote or Sample

Interested in the 40mil HDPE Dam Liner for your project? We welcome you to contact our sales team for a free quote, technical datasheet, or product sample. Whether you're working on a small pond or a large dam, our experienced team will help you choose the right liner thickness and specifications tailored to your needs.