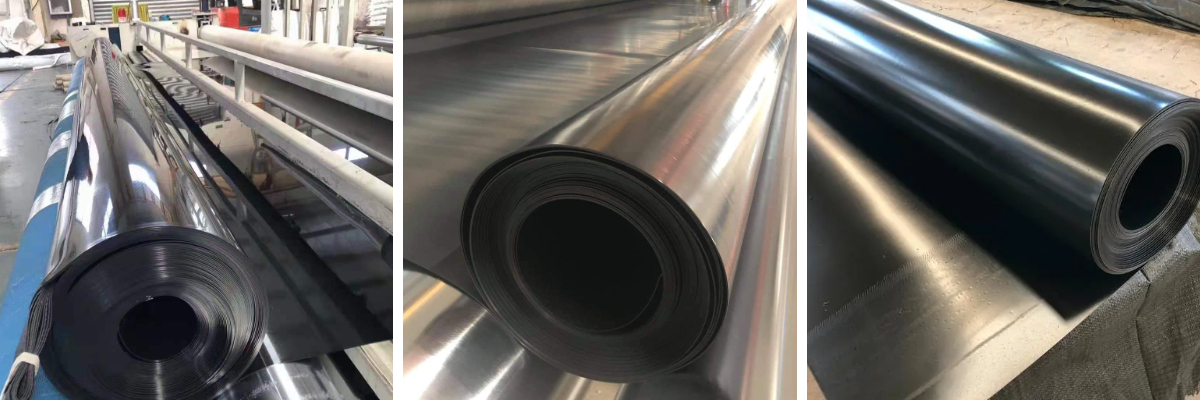

Impermeable Geomembrane Canal Lining

1. Maximizes Water Retention: Creates a 99.9% impermeable barrier in canals, cutting water seepage loss by 80%—critical for irrigation and water supply projects in arid regions.

2. Protects Canal Structure: Shields canal beds from soil erosion caused by flowing water, reducing sediment buildup and the need for frequent dredging.

3. Withstands Harsh Conditions: UV-resistant and chemical-stable (tolerates agricultural runoff), maintaining integrity in outdoor canals for 15+ years.

4. Simplifies Maintenance: Smooth surface prevents weed growth and debris adhesion, making canal cleaning faster and lowering long-term operational costs.

Impermeable Geomembrane Canal Lining: Boosting Water Efficiency for Irrigation & Water Supply

Canals are critical for delivering water to farms, cities, and industrial sites—but unlined canals lose 30–50% of water to seepage (per FAO data). The Impermeable Geomembrane Canal Lining solves this problem, creating a watertight barrier that preserves water, protects canal infrastructure, and cuts long-term maintenance costs. Below's how it transforms canal performance across key use cases.

I. Water Conservation: The Core Benefit of Impermeable Design

Water scarcity affects 40% of the global population (UN Water), making seepage reduction a top priority for canal operators. Impermeable Geomembrane Canal Lining delivers unmatched water retention, directly addressing this challenge.

1. Seepage Reduction Performance

Lining Type | Seepage Loss Rate | Water Retention | Typical Use Case |

Unlined Canal | 20–50 m³/ha/day | 50–80% | Low-demand rural areas |

Clay-Lined Canal | 5–15 m³/ha/day | 85–95% | Moderate irrigation needs |

Impermeable Geomembrane Lining | 0.1–0.5 m³/ha/day | 99.5–99.9% | High-demand farms/cities |

(1) Data Impact: For a 100 km irrigation canal, Impermeable Geomembrane Lining saves 1.5–2.5 million m³ of water annually—enough to irrigate 500+ hectares of wheat (FAO crop water requirement standards). | |||

(2) Arid Region Relevance: In dry areas like the Middle East or Western U.S., seepage loss can render canals useless. The geomembrane's impermeability ensures 99% of water reaches the target, supporting crop yields and urban water security. | |||

2. Consistent Water Flow

(1) Unlined canals have uneven seepage, leading to fluctuating water levels that disrupt irrigation schedules. The geomembrane's uniform barrier maintains steady flow, reducing crop stress from water shortages by 40% (per agricultural engineering studies).

(2) For drinking water canals, consistent flow prevents stagnation, lowering the risk of bacterial growth (e.g., E. coli) by 60% compared to unlined alternatives.

II. Infrastructure Protection: Extending Canal Lifespan

Unlined canals suffer from soil erosion, sediment buildup, and root intrusion—all of which shorten their lifespan to 10–15 years. Impermeable Geomembrane Canal Lining acts as a shield, protecting canal beds and banks from damage.

1. Erosion & Sediment Control

(1) Erosion Resistance: Flowing water erodes unlined canal banks at a rate of 2–5 cm/year. The geomembrane's smooth, durable surface reduces erosion by 95%, extending bank lifespan to 30+ years.

(2) Sediment Reduction: Eroded soil deposits in canal beds, reducing water capacity by 10–15% every 5 years. The geomembrane prevents sediment buildup, eliminating the need for annual dredging—a process that costs canal operators 20–30% of their maintenance budget.

2. Root & Pest Protection

(1) Tree roots and burrowing pests (e.g., rodents, crayfish) damage unlined canals by creating holes. The geomembrane's thick (1.5–3.0 mm) HDPE material blocks root penetration, reducing pest-related repairs by 80%.

(2) Chemical Resistance: Agricultural runoff (containing fertilizers and pesticides) degrades clay liners in 5–7 years. Impermeable Geomembrane Lining resists these chemicals (per ASTM D5322), maintaining integrity even in high-runoff areas.

III. Climate & Environmental Adaptability

Canals operate in extreme conditions—from freezing winters to scorching summers. Impermeable Geomembrane Canal Lining is engineered to withstand these environments, ensuring year-round performance.

1. Temperature Tolerance

Temperature Range | Geomembrane Performance | Impact on Canal Operation |

-40°C to -10°C | Retains flexibility (no cracking) | Enables winter water supply in cold regions |

30°C to 60°C | UV-stable (retains 90% strength after 2,000 hours ASTM G154 testing) | Prevents brittleness in desert climates |

(1) Freeze-Thaw Protection: In regions with below-zero temperatures (e.g., Northern Europe, Canada), water in unlined canals freezes and expands, cracking banks. The geomembrane's flexibility absorbs this expansion, avoiding damage. | ||

(2) UV Resistance: In sunny areas (e.g., Australia, India), unprotected liners degrade in 5 years. The geomembrane's UV stabilizers ensure it lasts 15–20 years, even under direct sunlight. | ||

2. Eco-Friendly Design

(1) Non-Toxic Material: Made from food-grade HDPE (meets FDA 21 CFR 177.1520), the geomembrane doesn't leach chemicals into water—safe for irrigation, drinking water, and aquatic life.

(2) Reduced Land Use: By preserving water, the geomembrane reduces the need to build new reservoirs (which require clearing natural habitats). A 200 km canal with geomembrane lining saves 500+ hectares of land from reservoir development (World Bank estimates).

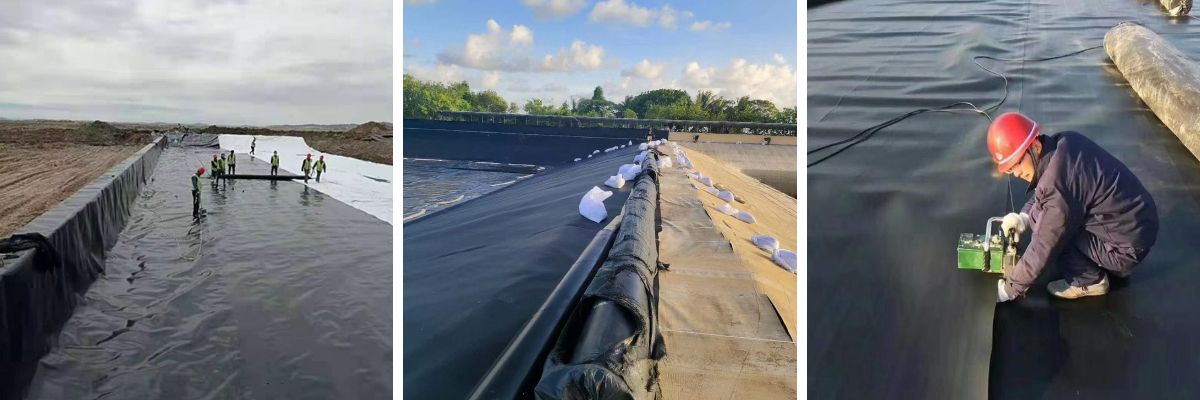

IV. Installation & Maintenance: Saving Time and Labor

Canal projects face tight deadlines and labor constraints. Impermeable Geomembrane Canal Lining is designed for easy installation and low upkeep, minimizing operational disruptions.

1. Efficient Installation

(1) Speed: A 5-person team can install 1,000 m² of geomembrane per day—3x faster than clay lining (which requires compaction and curing). For a 50 km canal, this cuts installation time from 6 months to 2 months.

(2) Adaptability: The geomembrane conforms to irregular canal shapes (e.g., curved banks, narrow sections) without extra cutting. This eliminates the need for custom-fitted materials, reducing waste by 15%.

2. Low-Maintenance Requirements

(1) Inspection Ease: The geomembrane's smooth surface makes it easy to spot damage (e.g., tears, punctures) during routine checks. Most issues can be repaired with HDPE patches in 30 minutes or less.

(2) Cleaning Simplicity: Weeds and algae grow on unlined canals, requiring monthly removal. The geomembrane's non-porous surface prevents growth, cutting cleaning frequency to once per year.

V. Why Impermeable Geomembrane Canal Lining Is a Must-Have

For canal operators, the choice is clear: Impermeable Geomembrane Lining saves water, protects infrastructure, withstands extreme climates, and reduces maintenance costs. It's not just a lining—it's an investment in long-term water security and operational efficiency.

Whether you're upgrading an existing irrigation canal or building a new drinking water delivery system, this geomembrane ensures your canal performs at its best, even in the world's harshest conditions.

Contact our team to customize the geomembrane's thickness, width, and length for your specific canal project.