2mm HDPE Geomembrana Dam Liner

Long - Term Durability: Offers high tensile strength, chemical resistance, and UV stability, ensuring a service life of several decades.

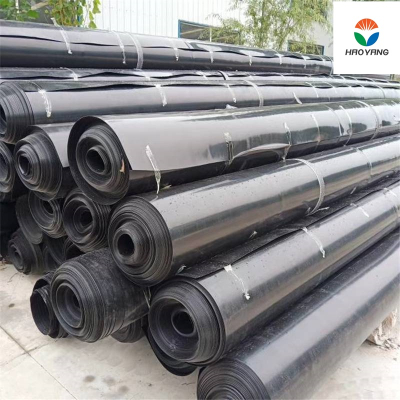

Easy Installation: Lightweight and flexible, enabling simple transportation and shaping to fit dam sites, with a straightforward installation process.

Cost - Effectiveness: Has a lower initial cost and lower life - cycle costs due to its long service life and low maintenance requirements.

2mm HDPE Geomembrane Dam Liner: A Reliable Solution for Water Resource Protection

Introduction

In the field of modern civil engineering and environmental protection, the demand for effective and durable water containment solutions is ever - increasing. Dams, as critical infrastructure for water storage, flood control, and hydroelectric power generation, require reliable liners to prevent water seepage and protect the surrounding environment. Among various liner materials, 2mm High - Density Polyethylene (HDPE) geomembrane has emerged as a popular choice for dam applications due to its excellent physical and chemical properties. This article aims to explore the characteristics, applications, and advantages of 2mm HDPE geomembrane dam liners in detail.

Characteristics of 2mm HDPE Geomembrane

Physical Properties

HDPE is a thermoplastic polymer with a high - density structure. The 2mm thickness of the geomembrane provides a balance between flexibility and strength. It has a high tensile strength, which allows it to withstand the mechanical stresses imposed by the water pressure and soil movement in dam structures. The typical tensile strength of 2mm HDPE geomembrane can reach up to 40 MPa (as shown in Table 1), making it capable of handling significant loads.

| Property | Value | Test Standard |

Thickness | 2.0 mm | ASTM D1777 |

Tensile Strength at Yield (MD/TD) | 35/35 MPa | ASTM D638 |

Elongation at Break (MD/TD) | 500/500% | ASTM D638 |

Puncture Resistance | 400 N | ASTM D4833 |

Carbon Black Content | 2 - 3% | ASTM D1603 |

Chemical Resistance

HDPE geomembrane is highly resistant to a wide range of chemicals, including acids, bases, and salts. This property is crucial for dams, as the water stored in them may contain various dissolved substances. The chemical stability of HDPE ensures that the geomembrane does not degrade over time when exposed to such environments. It can also resist the effects of biological agents, such as bacteria and fungi, which may be present in the soil and water around the dam.

Environmental Durability

UV resistance is another important characteristic of HDPE geomembrane. It can withstand long - term exposure to sunlight without significant degradation. This is particularly important for dams that are located in open - air environments. The addition of carbon black during the manufacturing process enhances the UV stability of the material, ensuring that the geomembrane can maintain its integrity for many years.

Applications in Dam Construction

Seepage Control

The primary function of a dam liner is to prevent water seepage through the dam structure. 2mm HDPE geomembrane is used as a barrier layer to reduce the permeability of the dam. It is placed on the upstream and downstream faces of the dam, as well as in the foundation area. By creating a continuous and impermeable layer, it effectively reduces the loss of water from the reservoir and prevents the erosion of the dam foundation.

Environmental Protection

In addition to seepage control, HDPE geomembrane also plays a role in environmental protection. It prevents the contamination of groundwater by the impurities in the reservoir water. This is especially important in areas where the water is used for drinking, irrigation, or industrial purposes. The geomembrane acts as a barrier, preventing the migration of pollutants from the dam into the surrounding soil and groundwater.

Rehabilitation of Existing Dams

Many existing dams are in need of rehabilitation due to aging or damage. 2mm HDPE geomembrane can be used to repair and upgrade these dams. It can be installed over the existing dam structure to provide an additional layer of protection. This approach is cost - effective compared to rebuilding the entire dam, and it can extend the service life of the existing infrastructure.

Advantages of 2mm HDPE Geomembrane Dam Liner

Long - Term Durability

The combination of high tensile strength, chemical resistance, and UV stability makes 2mm HDPE geomembrane a highly durable material. It can withstand the harsh conditions of dam environments for decades. This long service life reduces the need for frequent maintenance and replacement, resulting in significant cost savings over the long term.

Easy Installation

HDPE geomembrane is lightweight and flexible, which makes it easy to transport and install. It can be cut and shaped to fit the specific requirements of the dam site. The installation process can be carried out using standard construction equipment, and it does not require specialized skills. This ease of installation can shorten the construction period and reduce labor costs.

Cost - Effectiveness

Compared to other liner materials, such as clay or concrete, 2mm HDPE geomembrane is more cost - effective. It has a lower initial cost, and its long service life and low maintenance requirements result in lower overall life - cycle costs. Additionally, the ease of installation further reduces the construction costs, making it an attractive option for dam projects.

Case Studies

Project A: A Small Reservoir Dam

In a small reservoir dam project, 2mm HDPE geomembrane was used as the main liner material. The dam had a height of 15 meters and a storage capacity of 500,000 cubic meters. The geomembrane was installed on the upstream face of the dam and in the foundation area. After installation, the seepage rate of the dam was significantly reduced, and the water loss was minimized. The project was completed within a short period, and the cost was within the budget.

Project B: A Large Hydroelectric Dam

In a large hydroelectric dam project, 2mm HDPE geomembrane was used to rehabilitate an existing dam. The dam had been in operation for over 30 years and was showing signs of seepage. The geomembrane was installed over the existing concrete structure, providing an additional layer of protection. After rehabilitation, the seepage rate was reduced by 80%, and the service life of the dam was extended by at least 20 years.

Conclusion

In conclusion, 2mm HDPE geomembrane is a reliable and cost - effective solution for dam liner applications. Its excellent physical and chemical properties, along with its ease of installation and long - term durability, make it an ideal choice for both new dam construction and the rehabilitation of existing dams. By using 2mm HDPE geomembrane, we can effectively protect water resources, reduce environmental pollution, and ensure the safe and efficient operation of dams.