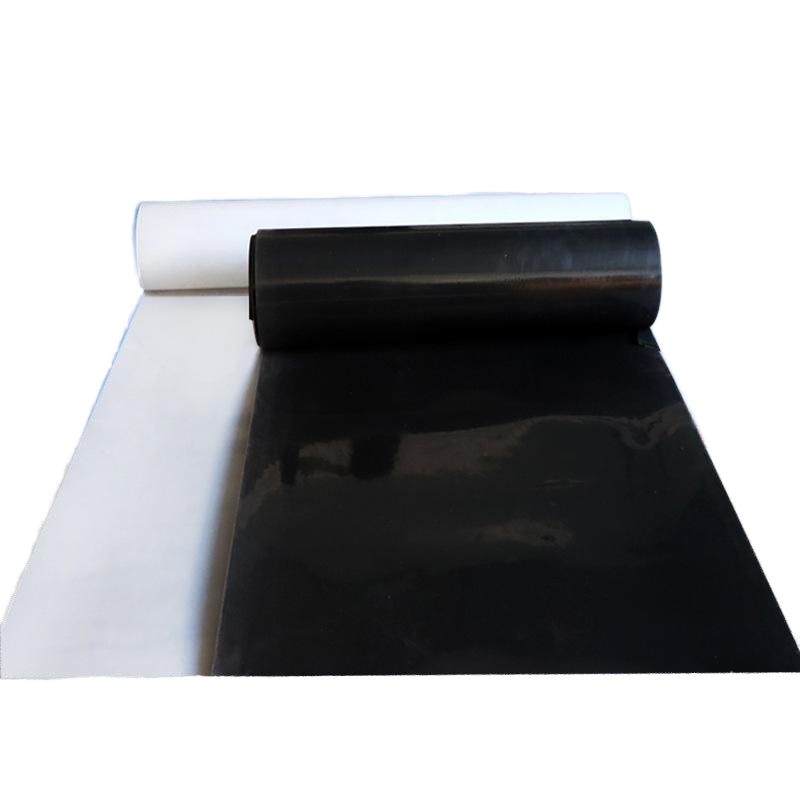

60mil HDPE Geomembrane Liner

Unmatched Chemical Resistance

Withstands exposure to acids, bases, salts, and hydrocarbons without degradation, ensuring containment integrity in harsh environments.

Exceptional Durability

UV-stable formulation and high puncture resistance extend lifespan to over 50 years in most applications.

Cost-Effective Installation

Lightweight and flexible design reduces labor and equipment costs during deployment, while seamless welding minimizes leakage risks.

60mil HDPE Geomembrane Liner: A Comprehensive Guide to Performance and Applications

High-density polyethylene (HDPE) geomembranes have emerged as a cornerstone material in modern environmental engineering, offering unparalleled durability and versatility for containment applications. Among the various thicknesses available, the 60mil HDPE geomembrane liner (equivalent to 1.52 mm) stands out as a robust solution for demanding projects requiring superior chemical resistance, mechanical strength, and long-term performance. This article explores the technical specifications, applications, and advantages of 60mil HDPE liners, supported by industry-standard data and real-world performance metrics.

Key Properties of 60mil HDPE Geomembrane Liners

HDPE geomembranes are engineered to withstand harsh environmental conditions, making them ideal for critical infrastructure projects. The 60mil thickness balances flexibility with puncture resistance, ensuring reliability in diverse scenarios. Below is a breakdown of its physical, chemical, and mechanical attributes:

Physical Properties

| Property | Value | Test Method |

Thickness | 60 mil (1.52 mm) | ASTM D5199 |

Density | 0.94–0.96 g/cm³ | ASTM D792 |

Melting Point | 125–135°C | ASTM D3418 |

Water Vapor Transmission | <0.01 g/m²/day | ASTM E96 |

UV Resistance | Excellent (>50 years) | ASTM G154 |

Mechanical Properties

| Property | Value | Test Method |

Tensile Strength (MD/TD) | 45 MPa / 40 MPa | ASTM D638 |

Elongation at Break | 700% (MD/TD) | ASTM D638 |

Puncture Resistance | 450 N | ASTM D4833 |

Tear Resistance | 150 N | ASTM D1004 |

Shear Strength | 35 kPa | ASTM D5321 |

Chemical Resistance

| Chemical | Resistance Level |

Acids (pH 0–14) | Excellent |

Bases | Excellent |

Salts | Excellent |

Hydrocarbons | Good |

Alcohols | Good |

Oxidizing Agents | Fair |

Applications of 60mil HDPE Geomembrane Liners

The 60mil HDPE liner’s robustness makes it suitable for a wide range of industrial, environmental, and municipal projects:

Landfill Liners and Covers

Acts as a primary barrier to prevent leachate contamination of soil and groundwater.

Complies with EPA regulations for hazardous waste containment.

Mining and Heap Leach Pads

Withstands aggressive chemical leaching solutions (e.g., cyanide, sulfuric acid).

Resists punctures from sharp ore fragments.

Water and Wastewater Management

Used in reservoirs, canals, and secondary containment ponds.

Prevents seepage in irrigation channels and aquaculture ponds.

Oil and Gas Infrastructure

Lines fracking fluid pits and drilling mud reservoirs.

Resists degradation from hydrocarbons and brine.

Agricultural Ponds and Lagoons

Retains water for irrigation and livestock.

Withstands UV exposure and agricultural chemicals.

Installation and Maintenance Best Practices

Proper installation is critical to maximizing the lifespan of a 60mil HDPE liner. Key steps include:

Site Preparation

Remove rocks, debris, and organic matter from the subgrade.

Ensure a minimum 2% slope for drainage.

Seaming and Welding

Use automated welding machines for seams (temperature: 350–400°C).

Conduct air pressure tests (ASTM D4437) to verify seam integrity.

Protection Layers

Install geotextile or nonwoven fabric above and below the liner to prevent punctures.

Use concrete blocks or anchors for wind uplift resistance.

Inspection and Repair

Perform visual inspections quarterly.

Repair tears or punctures immediately using HDPE patches and thermal welding.

Environmental and Economic Benefits

The 60mil HDPE geomembrane offers long-term cost efficiency due to its minimal maintenance requirements and extended service life. Studies show that HDPE liners can reduce containment costs by up to 40% over 30 years compared to alternative materials like clay or concrete. Additionally, their recyclability aligns with circular economy principles, with HDPE reclaim rates exceeding 80% in many regions.

Conclusion

The 60mil HDPE geomembrane liner represents a pinnacle of containment technology, combining technical precision with environmental stewardship. Its proven performance in landfills, mining operations, and water management systems underscores its role as a critical component of sustainable infrastructure. By prioritizing durability, chemical resistance, and ease of installation, this material continues to set the standard for modern geosynthetic solutions.