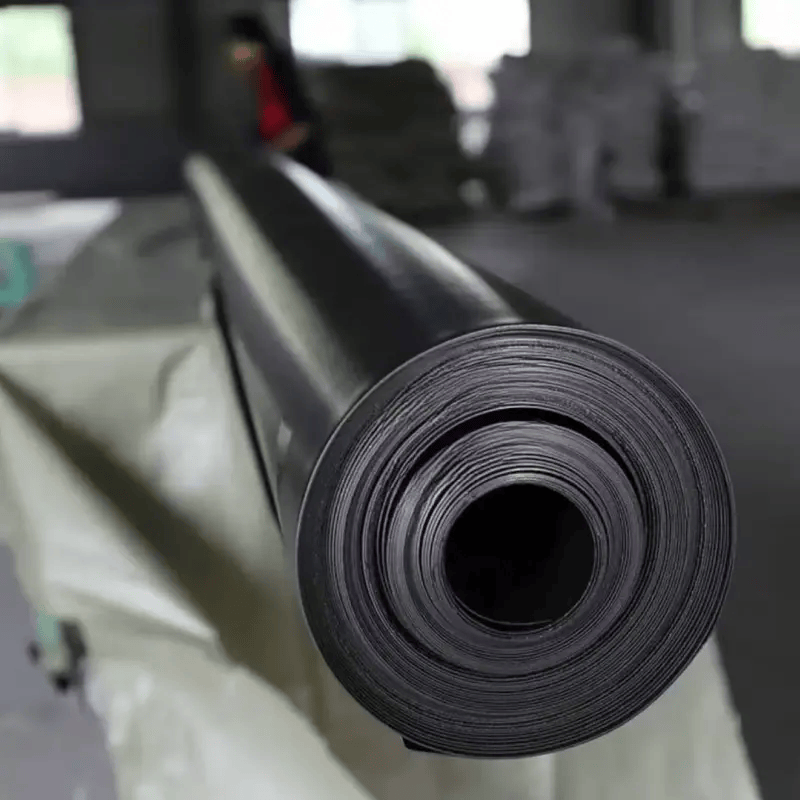

Ultraviolet-Resistant 0.75mm HDPE Geomembrane

1. Strong UV resistance

Adding special UV-resistant additives can provide long-term protection against sunlight exposure, preventing the material from aging and cracking.

2. Excellent anti-seepage performance

With a thickness of 0.75mm and the high-density characteristic of HDPE material, it forms an efficient anti-seepage barrier, effectively preventing water, sewage or chemical liquids from penetrating.

3. High physical strength

The material itself has high tensile strength and tear strength, capable of withstanding external forces such as construction compaction and foundation settlement.

4. Good chemical stability

It has strong resistance to common corrosive media such as acids, alkalis and salts.

1. Introduction

In the realm of modern engineering and environmental protection projects, the 0.75mm HDPE Geomembrane has emerged as a material of great significance. HDPE, which stands for High - Density Polyethylene, is a polymer renowned for its exceptional properties. This particular type of geomembrane, with a thickness of 0.75mm, strikes a balance between cost - effectiveness and performance, making it a popular choice across a wide array of applications.

2. Product Introduction

HDPE Geomembrane, short for High - Density Polyethylene Geomembrane, is a waterproof and impermeable material made from high - density polyethylene resin. It is widely used in various engineering projects to prevent the leakage of liquids and gases. The 0.75mm HDPE Geomembrane, with its specific thickness, has a set of unique characteristics.

The material's ultraviolet - resistant property is a result of the addition of special additives during the manufacturing process. These additives can absorb or reflect ultraviolet rays, effectively protecting the HDPE matrix from degradation caused by UV radiation. This makes the 0.75mm HDPE Geomembrane highly suitable for outdoor applications, such as the lining of reservoirs and canals, where it is constantly exposed to sunlight.

3.Manufacturing Process

The manufacturing process of the 0.75mm ultraviolet - resistant HDPE Geomembrane is a precise and well - controlled procedure.

Raw Material Selection: High - quality high - density polyethylene (HDPE) resin is the primary raw material. This resin should meet strict quality standards, with properties such as high density, good mechanical strength, and excellent chemical stability. Additionally, additives like ultraviolet stabilizers, antioxidants, and carbon black are added. Carbon black, for example, not only enhances the material's ultraviolet - resistant property but also improves its thermal stability.

Extrusion Molding: The mixed raw materials are fed into an extruder. Inside the extruder, they are heated to a high temperature until they reach a molten state. The molten HDPE is then forced through a die with a specific shape, which determines the thickness and width of the geomembrane. During this process, parameters such as temperature, pressure, and extrusion speed are carefully monitored and adjusted to ensure the uniform thickness and quality of the product.

Cooling and Solidification: After extrusion, the hot geomembrane is cooled rapidly to solidify it into the desired shape. This can be achieved through methods such as air cooling or water cooling. Cooling must be carried out evenly to prevent warping or uneven shrinkage of the geomembrane.

Quality Inspection: Every batch of 0.75mm HDPE Geomembrane undergoes a series of strict quality inspections. Visual inspection is first performed to check for surface defects such as holes, cracks, or impurities. Then, physical and chemical property tests are carried out, including thickness measurement, tensile strength testing, and chemical resistance testing.

4.Physical and mechanical properties of the 0.75mm HDPE Geomembrane:

Property | Value |

Thickness | 0.75mm ± 0.05mm |

Width | 6m (customizable) |

Weight per unit area | Approximately 900g/m² |

Tensile Strength (Longitudinal) | ≥25MPa |

Tensile Strength (Transverse) | ≥25MPa |

Elongation at Break | ≥700% |

Puncture Resistance | ≥500N |

Tear Resistance (Right - angle tear strength) | ≥110N/mm |

Physical Property | Value |

Density | 0.94 - 0.96 g/cm³ |

Melting Point | Approximately 130 - 135°C |

Thermal Expansion Coefficient | 1.2×10⁻⁴ - 1.6×10⁻⁴ /°C |

Water Absorption | ≤0.01% |

Permeability to Water Vapor | ≤1.0×10⁻¹² g·cm/(cm²·s·Pa) |

Chemical Property | Performance |

Acid Resistance | Resistant to dilute acids |

Alkali Resistance | Resistant to dilute alkalis |

Chemical Corrosion Resistance | Resistant to a wide range of common chemicals, including salts, organic solvents |

Oxidation Resistance | Good oxidation resistance with an oxidation induction time of ≥20 minutes at 200°C |

5.Application Areas

5.1 Environmental Protection Projects

In environmental protection projects, the 0.75mm ultraviolet - resistant HDPE Geomembrane plays a crucial role. In landfill sites, it serves as a key component of the anti - leakage system.

In Wastewater treatment plants, the geomembrane is used in areas such as sludge ponds and settling tanks. The HDPE Geomembrane prevents the leakage of sludge - related substances into the soil, protecting the soil quality and groundwater resources.

5.2 Water Conservancy Projects

For water conservancy projects, the 0.75mm HDPE Geomembrane is essential for ensuring the safety and efficiency of water - retaining structures. In reservoirs, it is installed on the bottom and side slopes.

In dams, the geomembrane can be used as an anti - seepage layer. Dams are large - scale water - conservancy structures that need to withstand significant water pressure. The 0.75mm HDPE Geomembrane, with its good tensile strength and puncture resistance, can resist the pressure of the water and the mechanical stress from the dam body, preventing seepage and ensuring the stability of the dam.

5.3 Agricultural Applications

In the agricultural sector, the 0.75mm ultraviolet - resistant HDPE Geomembrane has a wide range of applications. In aquaculture, such as in fish ponds and shrimp ponds, it is used as a lining material.

In irrigation systems, the HDPE Geomembrane can be used in reservoirs and water storage tanks. These structures store water for agricultural irrigation. In some areas with water - scarce conditions, the efficient water - storage function of the HDPE Geomembrane - lined reservoirs and tanks can help to better manage water resources and support agricultural activities.

5.4 Other Fields

In the mining industry, the 0.75mm HDPE Geomembrane is used in areas such as tailings ponds. The geomembrane prevents the leakage of these harmful substances into the soil and groundwater, reducing the environmental impact of mining activities.

In transportation infrastructure, for example, in the construction of roadbeds in areas with high groundwater levels, the HDPE Geomembrane can be used as an anti - seepage layer.

In the petrochemical industry, the geomembrane is used in the lining of storage tanks and reaction pools.

6.Conclusion

In conclusion, the 0.75mm ultraviolet - resistant HDPE Geomembrane is a remarkable material with outstanding physical, mechanical, and chemical properties. Its high tensile strength, excellent puncture and tear resistance, along with remarkable chemical and ultraviolet resistance, make it suitable for a diverse range of applications.

From environmental protection projects like landfills and sewage treatment plants to water conservancy projects such as reservoirs and dams, and even in agricultural and other industrial fields, this geomembrane has proven its value in preventing leakage, protecting the environment, and ensuring the stability and efficiency of engineering structures. The case studies further demonstrate its effectiveness and cost - effectiveness in practical applications.

With the continuous development of infrastructure and environmental protection industries, the demand for high - quality geomembranes like the 0.75mm ultraviolet - resistant HDPE Geomembrane is expected to grow. It will continue to play a crucial role in safeguarding the environment, conserving water resources, and promoting sustainable development in various engineering projects.