HDPE Geomembrane Liner: Cost-Effective Waterproofing Solution

Strong Puncture Resistance – Effectively withstands sharp objects and uneven surfaces.

Low Permeability – Maintains a stable barrier, minimizing water loss over time.

High Tensile Strength – Performs well under pressure and ground movement.

Low Maintenance – Reduces long-term repair costs and downtime.

Excellent Seam Strength – Welded joints provide reliable, leak-free performance.

Lightweight & Flexible – Easy to transport, handle, and install in various projects.

Waterproofing plays a crucial role in modern infrastructure, environmental protection, and agricultural development. As projects become larger and more demanding, the materials used must offer not only strong performance but also long-term economic benefits. HDPE geomembrane liner has become one of the most popular solutions for contractors, engineers, and farmers because it delivers reliable waterproofing at a competitive cost. Its strength, flexibility, and durability make it an excellent choice for a wide range of applications.

1. A Reliable Barrier Against Seepage

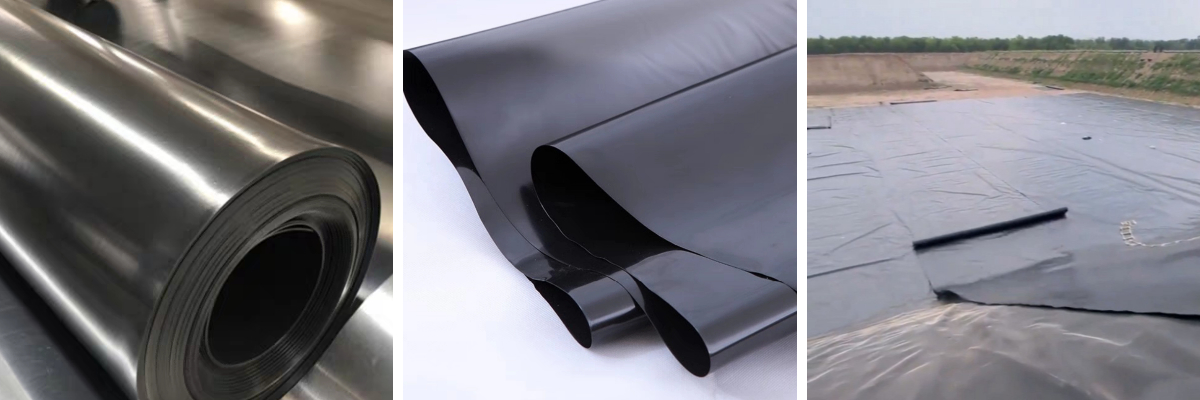

The primary function of an HDPE geomembrane liner is to create a solid, impermeable barrier. Its low permeability effectively prevents water loss, seepage, and leakage. Whether it’s used in reservoirs, fish ponds, landfills, or canals, the liner ensures that water remains where it’s needed. Unlike traditional methods such as compacted clay, HDPE liners maintain consistent waterproofing performance for many years with minimal maintenance.

2. Strong and Durable for Harsh Conditions

Projects often face challenging environments—rough ground, high water pressure, or exposure to UV radiation. HDPE geomembrane liner is designed to handle these conditions. It resists punctures from rocks and roots, performs well under stress, and maintains flexibility even after years of service. Its high tensile strength allows it to adapt to ground movement without tearing or cracking, ensuring long-term protection and stability.

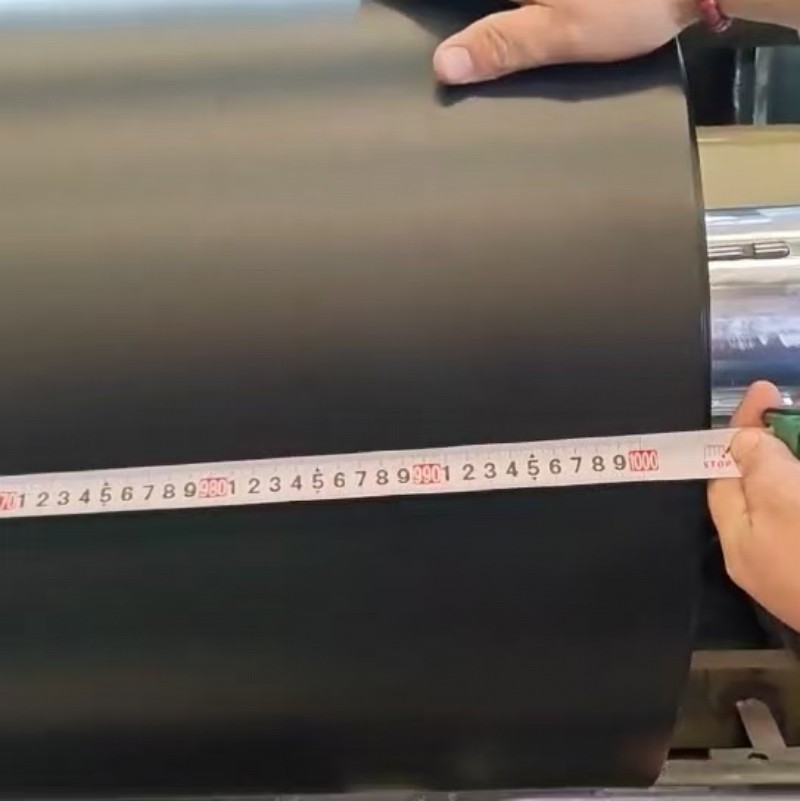

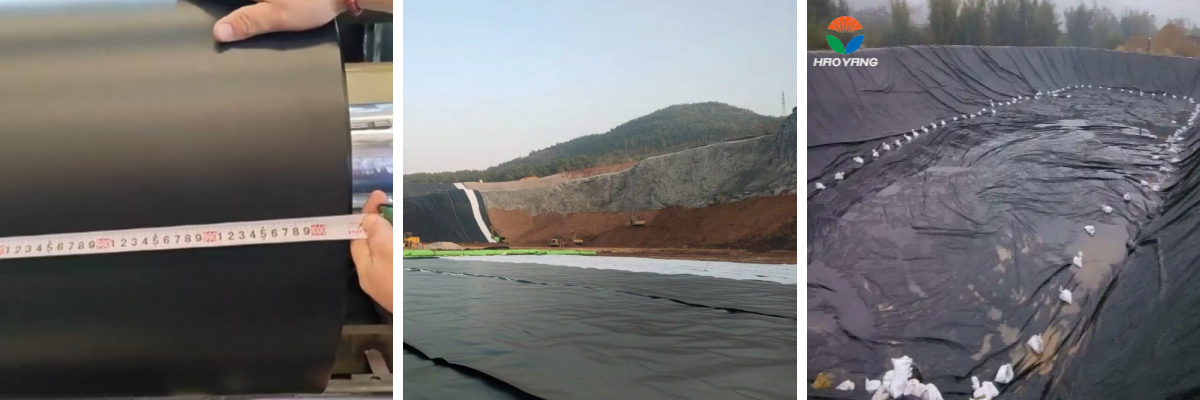

3. Easy Installation, Lower Labor Costs

Another advantage of HDPE geomembrane liner is its ease of installation. The liner is lightweight and easy to transport, which speeds up the construction process. On-site welding creates strong, leak-free seams that perform well under pressure. Compared with concrete structures or clay liners, installation is faster and requires less manpower, reducing overall project costs.

4. Excellent Seam Strength and Leak Prevention

A waterproofing system is only as strong as its weakest point. For HDPE liners, the seams are critical. By using professional thermal fusion welding techniques, installers can achieve joints that are even stronger than the liner itself. This ensures long-lasting leak protection and minimizes the risk of future repair work. Properly installed HDPE liners can maintain their integrity for decades.

5. Long-Term Economic Benefits

While initial material costs are important, the real value of HDPE geomembrane liner comes from its long-term performance. Its durability reduces the need for frequent maintenance or replacement. Projects benefit from lower life-cycle costs, making it a smart investment for governments, industries, and private sectors. Over time, the cost savings from reduced water loss, minimal maintenance, and extended service life make HDPE liners one of the most economical waterproofing solutions available.

6. Versatile Applications Across Industries

HDPE geomembrane liner is widely used in different sectors, reflecting its versatility and reliability. Common applications include:

Agriculture: Irrigation ponds, canals, and water storage tanks.

Aquaculture: Fish and shrimp farming ponds.

Infrastructure: Dams, reservoirs, and flood control projects.

Waste Management: Landfills and hazardous waste containment.

Mining: Leach pads and tailing storage facilities.

Its adaptability to various terrains and climates makes it suitable for both large infrastructure and small farm projects.

7. Environmentally Responsible Choice

In addition to its practical benefits, HDPE geomembrane liner supports environmental protection efforts. By preventing water and chemical seepage, it helps protect soil and groundwater. It’s a non-toxic, recyclable material that aligns with sustainable construction practices. Many modern projects use HDPE liners not only for cost savings but also to meet strict environmental standards and regulations.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

HDPE geomembrane liner is more than just a waterproofing material—it’s a smart, cost-effective solution for modern engineering and environmental projects. Its strength, flexibility, and low permeability provide long-lasting protection. Easy installation and low maintenance make it an economical choice over the life of the project.

Whether you’re lining a reservoir, constructing a pond, or building a landfill, HDPE geomembrane liner delivers dependable performance at a reasonable cost. Choosing a high-quality liner from a reliable source factory ensures that your project will stand the test of time.

If you’re looking for a trusted supplier of 100% virgin HDPE geomembrane liners, contact us today for professional support and competitive pricing tailored to your project needs.