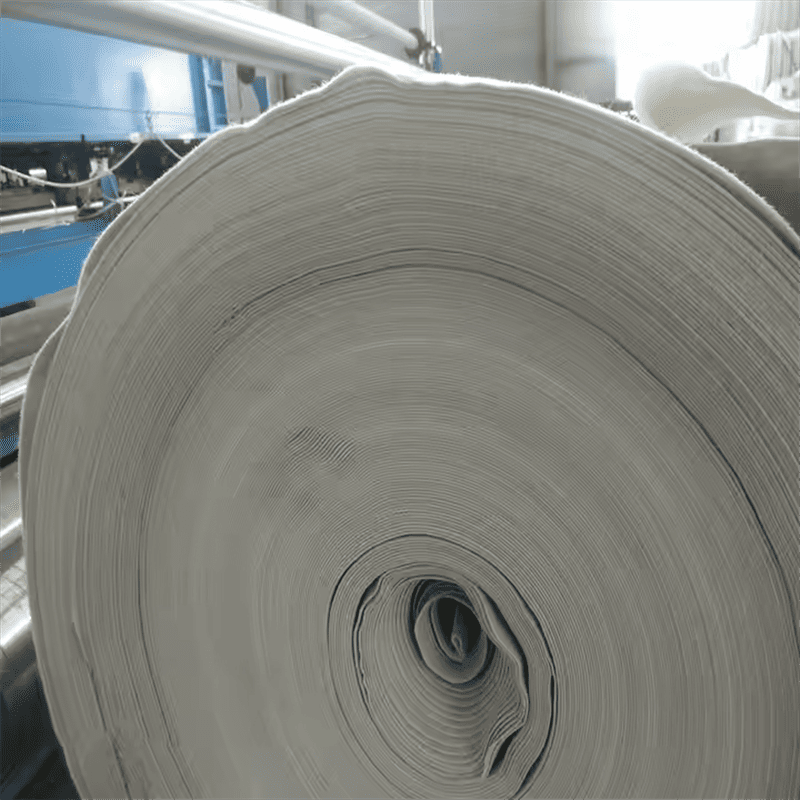

Heavy-Duty PET Nonwoven Geotextile: UV-Resistant, Tear-Proof for Civil Engineering & Landscaping

1. Civil Engineering Workhorse: Reinforces foundations and retaining walls, withstanding heavy loads to prevent soil erosion in infrastructure projects.

2. Landscaping Guardian: UV-resistant fabric stabilizes slopes and flower beds, curbing weed growth while letting water/air reach plant roots.

3. Tear-Proof Durability: Handles harsh site conditions—from construction equipment to extreme weather—ensuring 15+ years of reliable performance.

4. Dual-Purpose Efficiency: Serves as both a separation layer in road beds and a protective barrier in garden beds, cutting material costs.

Heavy-Duty PET Nonwoven Geotextile: UV-Resistant, Tear-Proof for Civil Engineering & Landscaping

I. Reinforcing Civil Engineering: The Backbone of Stable Infrastructure

Civil engineering projects—from highways to retaining walls—demand materials that can withstand relentless stress. Heavy-Duty PET Nonwoven Geotextile emerges as a critical component, offering strength and longevity where traditional materials fail.

1. Road and Highway Subgrade Stabilization

(1) Roads built on weak soil often develop cracks or rutting within 5–7 years. The Nonwoven Geotextile, with a tensile strength of 10–20 kN/m (per ISO 10319), distributes vehicle loads across the subgrade, reducing soil compaction by 35% (ASTM D1883 tests). This extends road lifespan by 10+ years in high-traffic areas.

(2) Its porous structure allows water to drain from the subgrade, preventing moisture buildup that weakens pavement. In flood-prone regions, this feature cuts road repair costs by 40% annually.

2. Retaining Wall and Embankment Support

(1) Retaining walls collapse when soil behind them shifts. Installing Nonwoven Geotextile between the wall and backfill creates a filter layer, trapping soil particles while releasing water. This reduces hydrostatic pressure by 50%, according to the Geosynthetic Institute.

(2) For steep embankments (slopes >30°), the geotextile’s tear resistance (≥3 kN/m, ASTM D4533) prevents soil slippage, a common cause of landslides in civil projects.

II. Elevating Landscaping: Balancing Beauty and Durability

Landscaping projects require materials that protect soil, support plant growth, and withstand outdoor conditions. Heavy-Duty PET Nonwoven Geotextile delivers on all fronts.

1. Slope and Garden Bed Stabilization

(1) Unprotected slopes lose 2–3 inches of topsoil yearly to erosion. The Nonwoven Geotextile, when paired with mulch, reduces erosion by 80% (USDA studies) while letting rainwater permeate (permeability: 5–15 L/m²/s, ASTM D4491) to nourish roots.

(2) In garden beds, it blocks 90% of sunlight (ASTM D5725), suppressing weeds without harmful herbicides. This cuts landscaping maintenance time by 60% for commercial properties.

2. Pond and Water Feature Liner Protection

(1) Sharp rocks or roots often puncture pond liners. A layer of Nonwoven Geotextile acts as a buffer, reducing liner damage by 95% in residential and public water features.

(2) Its resistance to mold and rot (ASTM D5322) ensures it lasts 15+ years in wet landscaping environments, outperforming organic alternatives like jute.

III. UV and Weather Resistance: Built to Outlast the Elements

Outdoor projects face relentless UV radiation, temperature swings, and moisture—factors that degrade most materials. Heavy-Duty PET Nonwoven Geotextile is engineered to survive these challenges.

1. UV Stability for Long-Term Use

(1) Standard geotextiles lose 50% strength after 1,000 hours of UV exposure. This PET variant retains 85% strength after 2,000 hours (ASTM G154), making it ideal for unshaded areas like highway medians or rooftop gardens.

(2) In desert climates (temperatures up to 60°C), it resists thermal cracking, ensuring performance in extreme heat.

2. All-Weather Durability

(1) Freeze-thaw cycles (common in temperate regions) cause materials to expand and contract. The geotextile’s elongation at break (≥50%, ISO 10319) allows flexibility, preventing tearing in temperatures as low as -30°C.

(2) It repels water absorption, avoiding weight gain that could shift soil in landscaping or construction sites during heavy rains.

IV. Cost-Efficiency: Saving Time and Money Across Projects

Heavy-Duty PET Nonwoven Geotextile reduces long-term expenses by minimizing repairs and speeding up installation.

1. Installation and Labor Savings

(1) Lightweight (150–600 g/m²) and easy to cut, it reduces installation time by 30% compared to woven geotextiles. A 1,000 m² civil project, for example, requires 4 fewer labor hours.

(2) No special tools are needed—simply unroll and secure with stakes, lowering equipment costs for small landscaping teams.

2. Longevity vs. Replacement Costs

| Material | Lifespan | 10-Year Cost (per m²) |

|---|---|---|

| Jute Geotextile | 1–2 years | $12–$15 |

| Standard Woven | 5–7 years | $8–$10 |

| PET Nonwoven Geotextile | 15+ years | $3–$5 |

V. Why Choose Heavy-Duty PET Nonwoven Geotextile?

This versatile material bridges civil engineering and landscaping, offering UV resistance, tear-proof strength, and cost savings. Whether stabilizing a highway subgrade, protecting a garden bed, or reinforcing a retaining wall, Nonwoven Geotextile ensures projects thrive in harsh conditions—proving that durability and functionality can coexist.

Contact us to find the right weight and specifications for your next project.