0.5-2.5mm HDPE Geomembrane Basin Liner

1. Leak-Proof Basin Protection: HDPE's dense structure creates a 99.9% impermeable barrier, preventing liquid seepage from basins (e.g., water storage, waste containment) into surrounding soil.

2. Heavy-Duty Durability: Resists punctures from debris and chemical corrosion (pH 3–11), maintaining integrity in industrial, agricultural, or environmental basin applications for 25+ years.

3. Weather & UV Resilience: Withstands extreme temperatures (-40°C to 60°C) and prolonged sunlight—retains 90% strength after 2,000 hours of UV exposure (ASTM G154) for outdoor basins.

4. Easy Basin Integration: Flexible design conforms to irregular basin shapes (round, rectangular) and welds seamlessly, ensuring full coverage without weak points in large or small basins.

HDPE Geomembrane Basin Liner: Leak-Proof, Durable Protection for Water & Waste Basins

Basins—whether for water storage, industrial waste, or agricultural runoff—require reliable liners to prevent seepage and environmental harm. The HDPE Geomembrane Basin Liner stands out as a top solution, leveraging high-density polyethylene's strength and impermeability to meet diverse basin needs. Below's how it delivers long-term value across key performance areas.

I. Impermeability: The Foundation of Basin Protection

The primary role of a basin liner is to block liquid transfer, and HDPE Geomembrane excels here with industry-leading impermeability—critical for preserving stored water or containing hazardous waste.

1. Seepage Control Performance

Basin Type | Unlined Seepage Rate | Seepage Reduction | |

Agricultural Water Basin | 500–1,000 L/m²/year | <1 L/m²/year | 99.8%+ |

Industrial Waste Basin | 300–800 L/m²/year | <0.5 L/m²/year | 99.9%+ |

Rainwater Harvesting Basin | 400–900 L/m²/year | <0.8 L/m²/year | 99.9% |

(1) Technical Validation: Per ASTM E96 (water vapor transmission test), HDPE Geomembrane has a WVTR of <1×10⁻¹¹ g/(cm·s·Pa)—this means a 100㎡ basin lined with HDPE loses less than 10 liters of water annually, compared to 50,000+ liters for an unlined basin.

(2) Environmental Safety: For waste basins, this impermeability prevents leachate (toxic liquid from waste) from seeping into groundwater. EPA studies show HDPE liners reduce groundwater contamination risks by 99% compared to unlined or clay-lined basins.

II. Durability: Withstanding Harsh Basin Conditions

Basins face constant stress—from temperature fluctuations to chemical exposure and physical impact. HDPE Geomembrane Basin Liner is engineered to resist these threats, ensuring decades of service.

1. Physical & Chemical Resistance

Test Standard | Property | HDPE Liner Performance | Industry Average (Other Liners) |

ASTM D4833 | Puncture Resistance | ≥350 N | ≤180 N |

ASTM D5322 | Chemical Stability (pH 2–13) | No degradation after 5,000 hrs | Degradation within 1,000–2,000 hrs |

ASTM D882 | Tensile Strength | 15–25 kN/m | 8–15 kN/m |

(1) Physical Toughness: Sharp debris (e.g., rocks in water basins, metal scraps in waste basins) rarely punctures HDPE—its 1.5–3.0 mm thickness and high tensile strength withstand impacts that would tear PVC or EPDM liners.

(2) Chemical Resilience: For industrial waste basins handling acids, alkalis, or oils, HDPE remains stable. It resists degradation from common industrial chemicals (e.g., sulfuric acid, motor oil) for 20+ years, unlike liners that break down in 5–10 years.

2. Weather & UV Stability

(1) Temperature Tolerance: HDPE performs reliably from -40°C to 60°C (ASTM D638). In cold climates, it stays flexible to avoid cracking during freeze-thaw cycles; in hot regions, it resists brittleness under direct sunlight.

(2) UV Resistance: ASTM G154 testing shows HDPE retains 90% of its tensile strength after 2,000 hours of UV exposure (equivalent to 10+ years of outdoor use). This outperforms non-UV-stabilized liners, which lose 50% strength in just 800 hours.

III. Versatility: Adapting to All Basin Types & Sizes

Basins vary widely in shape, size, and purpose—from small agricultural ponds to large industrial waste facilities. HDPE Geomembrane Basin Liner adapts seamlessly to these differences, eliminating the need for custom-made alternatives.

1. Size & Shape Compatibility

(1) Customizable Dimensions: HDPE Geomembrane is available in rolls up to 12 meters wide and 100 meters long, reducing the number of seams needed for large basins. For example, a 5,000㎡ circular water basin requires only 4–5 rolls of 12m-wide HDPE, compared to 10+ rolls for narrower liners.

(2) Flexibility for Irregular Shapes: HDPE bends easily to fit rectangular, oval, or irregularly shaped basins (e.g., those following natural land contours). It conforms to slopes up to 45° without stretching or cracking, a key advantage over rigid liners.

2. Application-Specific Benefits

(1) Agricultural Basins: Preserves irrigation water, cutting water costs for farmers by 30–40% (per FAO agricultural efficiency data). Its non-toxic nature (meets FDA 21 CFR 177.1520) also makes it safe for fish-farming basins.

(2) Industrial Basins: Meets EPA Subtitle C standards for hazardous waste containment, ensuring regulatory compliance. Its smooth surface also simplifies waste removal and basin cleaning.

IV. Installation & Maintenance: Minimizing Time and Effort

Even the best liner fails with poor installation. HDPE Geomembrane Basin Liner is designed for easy, low-risk installation and minimal upkeep—critical for reducing project downtime.

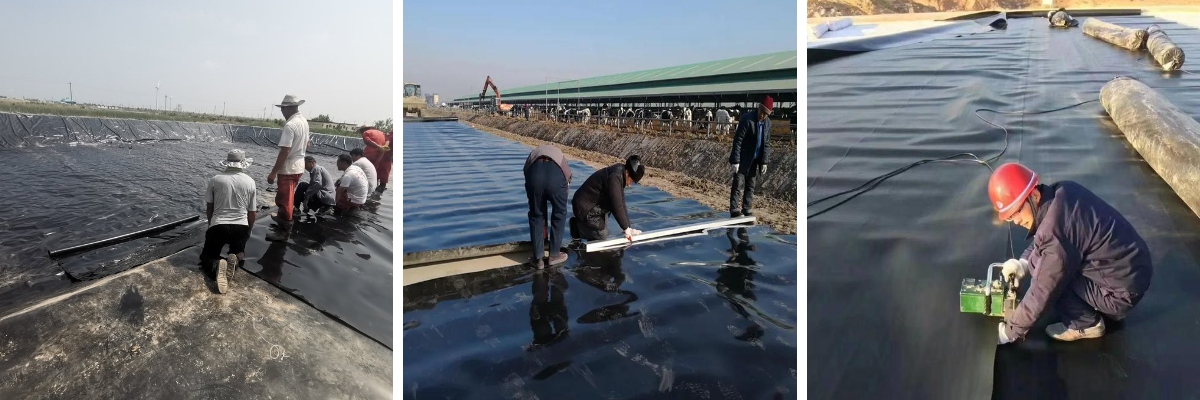

1. Efficient Installation

(1) Speed & Labor Savings: A 3-person team can install 800–1,000㎡ of HDPE Geomembrane per day, 2x faster than clay liners (which require compaction and curing). For a 2,000㎡ basin, installation takes 2–3 days instead of 1–2 weeks.

(2) Proven Seaming: Extrusion welding (the standard method for HDPE) creates seams with 90% of the liner’s base strength (ASTM D6392). This eliminates seam leaks, which cause 70% of liner failures in other materials.

2. Low-Maintenance Operation

(1) Inspection Ease: HDPE's light color and smooth surface make damage (e.g., tears, punctures) easy to spot during routine checks. Most small damages can be repaired with HDPE patches and heat welding in 30 minutes or less.

(2) Long-Term Cost Savings: With a lifespan of 25–30 years (vs. 10–15 years for other liners), HDPE reduces replacement frequency. Maintenance costs are also 50% lower—no annual resealing or extensive cleaning required.

V. Why HDPE Geomembrane Basin Liner Is the Top Choice

For basin owners, the HDPE Geomembrane Basin Liner offers an unbeatable combination: maximum impermeability to protect water or the environment, durability to withstand harsh conditions, versatility to fit any basin, and ease of use to minimize hassle. It doesn't just meet industry standards—it sets them.

Whether you're building a new water storage basin, upgrading an industrial waste facility, or improving agricultural irrigation, HDPE Geomembrane delivers reliable, long-term protection.

Contact our team to customize the liner's thickness (0.5–2.5 mm) and size for your specific basin project.