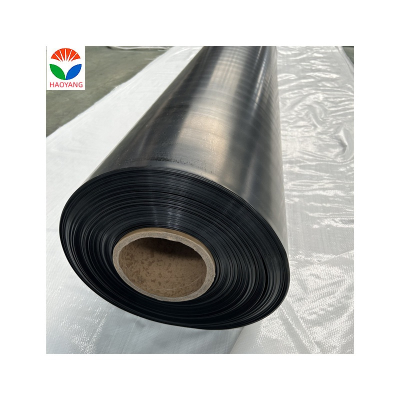

1mm Anti-Seepage HDPE Geomembrane

1. Enhanced waterproofing performance: The material density is increased by 1mm, with a permeability coefficient of ≤ 1.0 × 10⁻¹³ cm/s.

2. Superior mechanical strength: The tensile strength is ≥ 25 MPa, and the puncture resistance strength is ≥ 350 N. These values are 8% and 17% higher than those of the 0.75mm geomembrane

3. Enhanced environmental tolerance: The acid and alkali resistance range is extended to pH 1-14. It does not crack at -45℃, and retains 85% of the original strength after UV radiation for 800 hours.

4. Balanced construction cost-effectiveness: The width range is supported from 4 to 10 meters, reducing the number of seams.

1. Unbeatable Core Performance of 1mm Anti-Seepage HDPE Geomembrane

The 1mm anti-seepage HDPE geomembrane excels in critical metrics, outperforming thinner or lower-quality options. Its dense HDPE structure delivers unmatched anti-seepage, while robust mechanics handle harsh conditions.

| Performance Metric | 1mm Anti-Seepage HDPE Geomembrane | Industry Average (Thinner Membranes) |

| Permeability Coefficient | ≤1.0×10⁻¹³ cm/s | ≤1.0×10⁻¹² cm/s |

| Tensile Strength | ≥25 MPa | ≥20 MPa |

| Puncture Resistance | ≥350 N | ≥280 N |

| UV Resistance (800h) | Retains 85%+ tensile strength | Retains 70%-75% tensile strength |

This HDPE geomembrane resists -45℃ cold (no brittleness) and pH 1-14 chemicals, making it durable in diverse environments. For projects prioritizing long-term reliability, the 1mm anti-seepage HDPE geomembrane is non-negotiable.

2. Key Application Scenarios for 1mm Anti-Seepage HDPE Geomembrane

1.Waste Landfills: Blocks leachate from seeping into groundwater. A municipal landfill project cut contamination by 98% using this HDPE geomembrane.

2.Chemical Tanks: Withstands acids/alkalis, protecting soil from toxic spills—critical for refineries and wastewater plants.

3.Artificial Lakes: Reduces water loss by 70%+; a scenic lake project maintained stable levels year-round with this membrane.

4.Aquaculture: Prevents seepage and soil salinization, boosting fish farm water retention by 30%.

Every scenario relies on the 1mm anti-seepage HDPE geomembrane’s ability to perform under pressure.

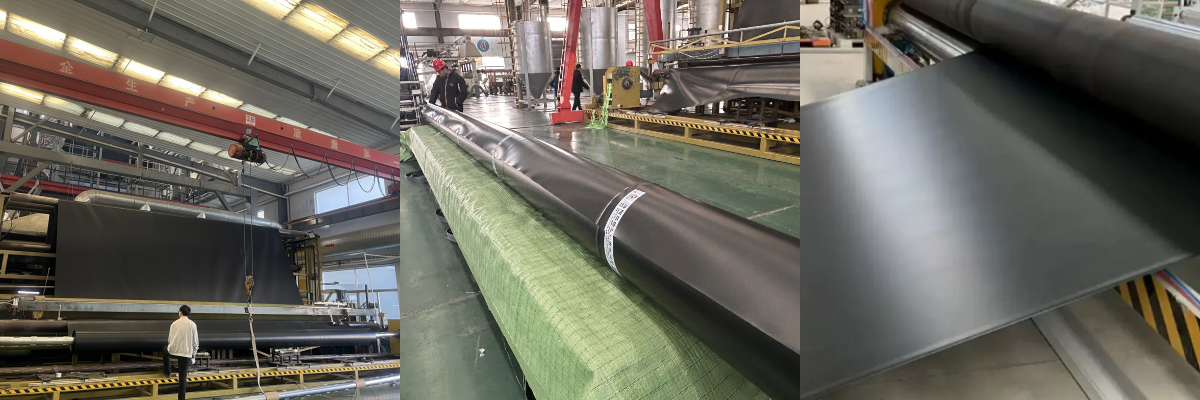

3. Simple Construction Guide for 1mm Anti-Seepage HDPE Geomembrane

Proper installation maximizes the HDPE geomembrane’s potential—follow these steps for leak-proof results:

1.Foundation Prep: Clear sharp debris, compact soil, and level surfaces to avoid puncturing the 1mm anti-seepage HDPE geomembrane.

2.Laying: Unroll from low to high terrain, leaving 10-15cm overlaps. Use 4-10m wide rolls to cut seam counts (fewer seams = less risk).

3.Welding: Use a hot-melt machine (180-220℃, 1.5-2m/min speed). Test seams via air pressure (0.2 MPa for 30 mins—no drop = pass).

4.Protection: Cover with geotextile/fine soil to shield from UV and damage.

4. How to Choose Quality 1mm Anti-Seepage HDPE Geomembrane

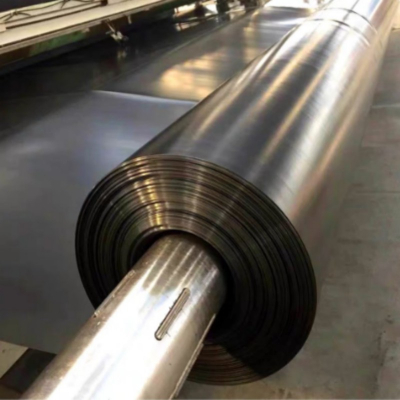

1.Standards: Verify compliance with GB/T 17643-2011 (China) or ASTM D4439 (US); ensure thickness tolerance (±5%) and OIT (≥20 mins at 190℃).

2.Certifications: Look for SGS/CE labels—proof of third-party testing.

3.Physical Checks: Inspect for smooth surfaces (no bubbles/cracks); bend samples—quality membranes stay flexible, not brittle.

Choosing certified 1mm anti-seepage HDPE geomembrane prevents project failures.

5. Cost-Effectiveness of 1mm Anti-Seepage HDPE Geomembrane

1.Long Life: 30-50 years vs. 10-15 years for PVC—cuts replacement costs.

2.Low Maintenance: Resists aging/corrosion; a water project reduced upkeep by 60% over 10 years.

3.Leak Prevention: Avoids fines from environmental spills—priceless for high-risk sites.

The 1mm anti-seepage HDPE geomembrane is an investment, not an expense.

6. Final Note

The 1mm anti-seepage HDPE geomembrane combines performance, versatility, and value—making it essential for modern engineering. Whether you’re building a landfill or lake, this HDPE geomembrane ensures your project’s success.