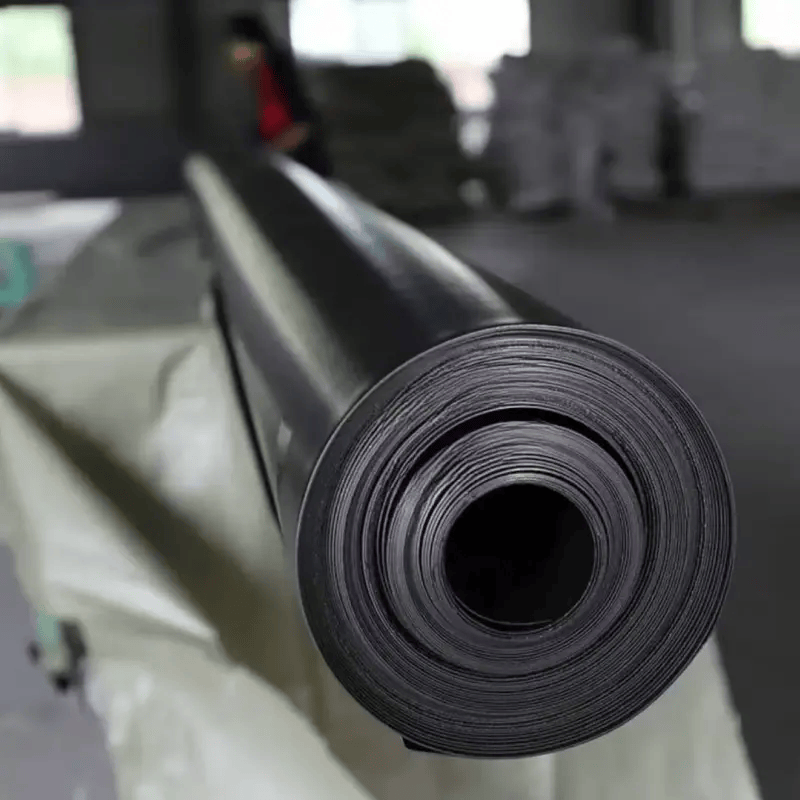

0.75mm Anti-Seepage HDPE Geomembrane

1. Superb water-proofing performance: The 0.75mm thick HDPE material has high density and can effectively prevent water, sewage, and chemical liquids from penetrating. The permeability coefficient is extremely low.

2. Excellent durability: It has outstanding resistance to aging, UV rays, and acid-base corrosion, and can be used for a long time in outdoor harsh environments without cracking or degradation.

3. Good mechanical properties: The tensile strength and tear strength are high, which can adapt to foundation settlement or external force impacts. It is not prone to damage during construction.

4. Economic practicality: The unit area cost is reasonable, and the construction is convenient and efficient without complex procedures.

Introduction to Geomembrane

0.75mm anti-seepage HDPE geomembrane, made from high-density polyethylene, has uniform thickness and a dense structure.

Its core advantage is extremely strong anti-seepage performance, with an extremely low permeability coefficient, capable of efficiently blocking water and chemical liquid penetration. It also has excellent anti-aging and acid-base resistance properties, is suitable for outdoor harsh environments, and has high tensile and tear strength, which can fit irregular terrain and is easy to install.

Technical Parameters

| Item | Technical Parameter/Property Index | Test Standard |

| Material | High-Density Polyethylene (HDPE) | GB/T 17643-2011 / ASTM D4439 |

| Thickness | 0.75mm (Tolerance: ±5%) | GB/T 6672-2001 / ASTM D3740 |

| Density | 0.940 - 0.965 g/cm³ | GB/T 1033.1-2008 / ASTM D1505 |

| Tensile Strength | ≥23 MPa (MD/TD) | GB/T 17643-2011 / ASTM D638 |

| Elongation at Break | ≥700% (MD/TD) | GB/T 17643-2011 / ASTM D638 |

| Tear Strength | ≥80 N (MD/TD) | GB/T 17643-2011 / ASTM D1004 |

| Puncture Resistance | ≥300 N | GB/T 17643-2011 / ASTM D4833 |

| Permeability Coefficient | ≤1.0×10⁻¹³ cm/s | GB/T 17643-2011 / ASTM D1653 |

| Oxidation Induction Time | ≥20 min (190℃) | GB/T 17643-2011 / ASTM D3895 |

| UV Resistance | Retain ≥80% of original tensile strength after 500h UV exposure | GB/T 17643-2011 / ASTM D4329 |

Core Performance And Dfferentiated Performance

1. Ultimate Water Resistance (Core): Permeability coefficient ≤ 1.0 × 10⁻¹³ cm/s. The dense molecular structure of HDPE can prevent water, sewage, and chemical liquids, far exceeding that of ordinary geotextiles or PVC membranes. It is suitable for strict waterproofing scenarios such as landfill sites, eliminating leakage pollution.

2. Super Durability (Core): Resists UV radiation for 500 hours while maintaining 80% tensile strength. Resistant to acids and alkalis (pH 2 - 13) and does not crack at - 40℃. Service life is 20 - 50 years, 30% more durable than LDPE membranes, significantly reducing long-term maintenance costs.

3. High Adaptability Mechanical Properties (Core): Tensile strength ≥ 23 MPa, elongation at break ≥ 700%. Can adapt to foundation settlement; puncture resistance ≥ 300N, can withstand sharp objects during construction, more suitable for complex terrain laying than composite geotextiles.

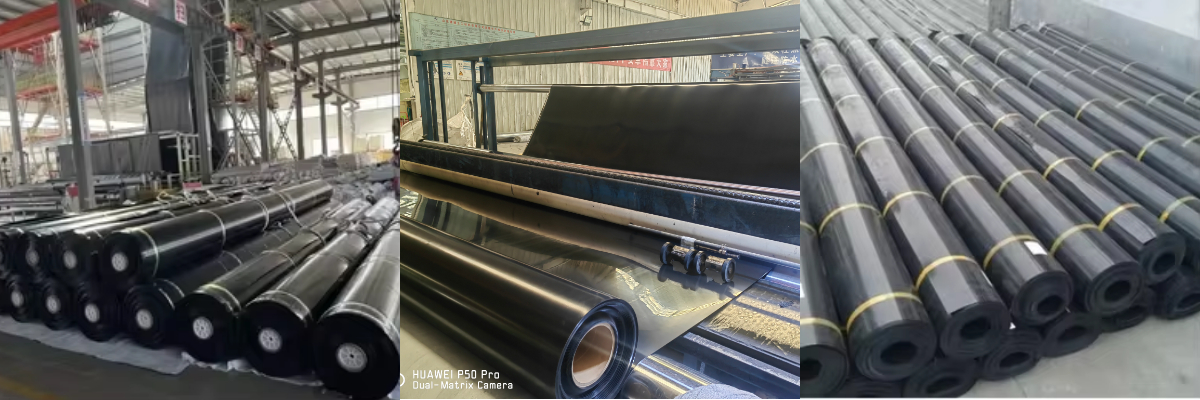

4. Efficient Construction (Differentiation): Width can reach 4 - 8m, fewer seams, and hot-melt welding (180 - 220℃) is easy to operate. Construction efficiency is 25% higher than EVA membranes, especially suitable for rapid advancement of large-scale projects.

5. High Cost-effectiveness (Differentiation): Unit area cost is only 60% of TPO waterproofing membranes, yet it has a longer lifespan and lower maintenance costs. In medium and large-scale water conservancy and environmental protection projects, the overall cost advantage is significant.

Application Scenarios And Cases

1. Leachate prevention for landfill sites: Applied to the bottom and the covering layer of the landfill, it prevents the leakage of leachate from polluting groundwater. For example, in a landfill site in Jinan, Shandong Province, after the change, the groundwater COD met the standards within 3 years, and the vegetation coverage reached 85%.

2. Artificial lake landscape project: Adapted to complex terrains such as mountains, it prevents water seepage and leakage. The landscape lake of a pumped storage power station used it for seepage prevention, with no loss of 4500 cubic meters of water storage volume, and it was suitable for spillway facilities.

3. Livestock farm manure treatment: As the main material for black membrane septic tanks, it prevents seepage and promotes anaerobic fermentation to produce biogas. It is suitable for the "water bubble manure" treatment of large pig farms, achieving zero discharge of manure and energy recovery.

4. Isolation of chemical wastewater tanks: Resistant to acid and alkali (pH 2-13) corrosion, it prevents the leakage of toxic waste liquids. It is used for seepage prevention of liquid storage tanks in chemical plants, resisting chemical erosion and ensuring soil safety.

5. Water conservancy channel seepage prevention: Reduces water loss during transportation, suitable for uneven terrain of the channels. It is laid on agricultural irrigation channels to improve water transmission efficiency and contribute to water-saving agriculture.

6. Hazardous waste disposal site: Isolates harmful substances such as heavy metals. Applied in a disposal site in Xinjiang, it solved the leakage problem and the soil quality reached the safety standard.

The Future Development Trend Of The Market

1. Market size and growth momentum: By 2025, the market size in China is expected to exceed 18 billion yuan, with a compound annual growth rate of 12%-15%. The core driving forces come from stricter environmental policies and increased infrastructure investment. The demand in three major fields - landfill sites, water conservancy projects, and mine restoration - accounts for over 70%. The major water conservancy projects in the 14th Five-Year Plan directly drive a demand increase of 250,000 tons.

2. Competitive landscape and industry concentration: The industry shows a trend of concentrated leadership, with the market share of the top five manufacturers rising from 48% in 2019 to 62% in 2023. The production capacity in Shandong, Jiangsu, and Zhejiang accounts for 63% of the national total. Xinjiang builds production bases relying on raw material advantages, and the self-sufficiency rate in the west has increased to 51%, with a CR5 concentration of 41%.

3. Policy and standard-driven upgrading: The newly revised GB/T17643 standard in 2025 raises the thickness and tensile strength indicators, forcing small and medium-sized enterprises to upgrade their technologies. It is estimated that 10%-15% of the backward production capacity will be eliminated. Environmental regulations drive the renovation of anti-seepage facilities for hazardous waste landfill sites, forming a 2.9 billion yuan special market.

4. Technology iteration and product upgrading: The trend of high-endization is obvious. The market share of high-strength membranes above 2.0mm reaches 47%, and the application of nanomodified membranes in chemical industries accounts for 15%. The anti-ultraviolet lifespan is extended to 30 years. Intelligent monitoring embedded in membranes and photocatalytic self-cleaning technology have become the focus of research and development. The penetration rate of high-end products will reach 40% by 2025.

5. Cost and price influencing factors: The cost of polyethylene resin accounts for 55%. The raw material price in 2024 was 8,900-10,200 yuan per ton, driving the price of 1.2mm specification membranes to 13-15 thousand yuan per ton. Certified products have a premium of 23%, and the premium space for differentiated products can reach 30%. However, the environmental compliance cost compresses the profit margin to 8%-9%.

6. Emerging markets and application expansion: Exports have grown at an average annual rate of 20%. The infrastructure boom in Southeast Asia has driven the proportion of exports to exceed 15%. The anti-seepage of photovoltaic fields has become a new blue ocean. It is expected that the market size will exceed 5 billion yuan in 2027. The intelligent anti-seepage system is piloted in Xiongan, and the annual scale may reach 800 million yuan after maturity.

The Advantages Of Haoyang Environmental

1. Leading in technology and quality control: Utilizing a five-layer co-extrusion and online roughening process, combined with a digital system for control, the membrane thickness is uniformly 0.75mm, and it has been certified by the CNAS laboratory. The indicators meet European and American standards.

2. Super anti-seepage and corrosion resistance: The permeability coefficient is ≤ 1×10⁻¹³ cm/s, resistant to over 80 chemical media, and the mechanical performance retention rate exceeds 95% in a 60-day strong acid environment. It is suitable for hazardous waste and chemical scenarios.

3. Full environmental adaptability: It remains flexible at -30℃, resistant to UV aging, and has a crack resistance of over 700 hours under environmental stress, with a tensile elongation rate of ≥ 700%. It is suitable for extremely cold and foundation settlement scenarios.

4. Construction and cost advantages: The width can reach 10m, with few seams, and the hot-melt welding is convenient; compared to traditional materials, the project cost can be saved by 50%, and the overall cost performance is high.