HDPE Liner For Waterproof Protection

1. Superior Waterproof Performance — Provides a strong and reliable waterproof barrier.

2. High Tensile and Tear Strength — Resists puncture, tearing, and heavy pressure.

3. Chemical and UV Resistance — Performs well under chemicals and sunlight exposure.

4. Long Service Life — Virgin HDPE ensures durable and long-lasting use.

5. Easy Installation and Welding — Welds quickly with secure, leak-free seams.

6. Cost-Effective Protection — Offers long-term performance with low maintenance.

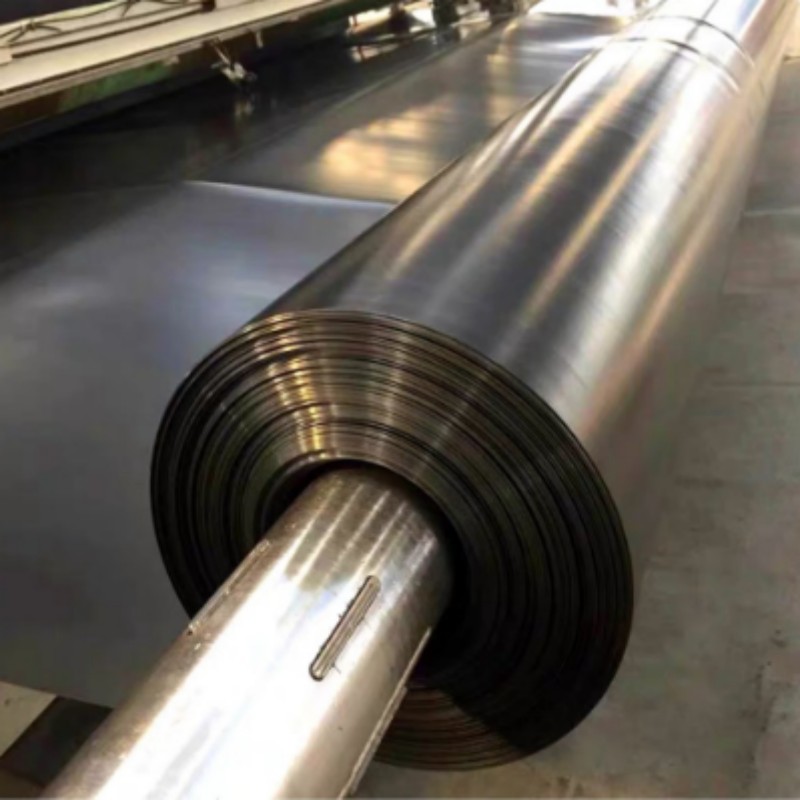

High-density polyethylene (HDPE) liners are widely recognized as the most reliable solution for waterproof protection in industrial, agricultural, and environmental projects. At Haoyang Environmental Co., Ltd., we provide high-quality HDPE geomembranes that combine durability, flexibility, and environmental safety, making them the top choice for projects worldwide.

Why Choose Haoyang HDPE Liners

100% Virgin Material: Produced with premium virgin HDPE to ensure superior chemical resistance and long-term durability.

Customizable Thickness & Width: From 0.2mm to 2.0mm, widths up to 10 meters, suitable for various project sizes.

High Tensile Strength & Flexibility: Adapts to uneven surfaces without cracking or tearing.

UV & Weather Resistant: Maintains performance under sunlight and harsh weather conditions.

Eco-Friendly & Safe: Prevents soil and groundwater contamination while meeting environmental regulations.

Cost-Effective: Long service life reduces maintenance and replacement costs.

Applications

HDPE liners are used in a wide range of applications:

Landfills & Waste Containment: Provides leak-proof protection and prevents soil contamination.

Ponds & Reservoirs: Ideal for aquaculture, irrigation tanks, and water storage systems.

Mining & Industrial Projects: Resistant to chemicals, acids, and alkalis in harsh environments.

Roads & Tunnels: Acts as a waterproof barrier for underground infrastructure projects.

Customer Reviews

“We installed Haoyang’s HDPE liner in our fish farming pond, and it has exceeded our expectations. The material quality and flexibility are unmatched.” – John M., USA

“Haoyang’s team provided excellent service and technical support. The HDPE liner performed perfectly for our landfill project.” – Maria L., Brazil

“Highly recommend Haoyang HDPE liners for any large-scale waterproofing project. Durable, reliable, and easy to install.” – Ahmed K., UAE

Production & Quality Assurance

Haoyang Environmental Co., Ltd. operates a modern production facility with advanced extrusion technology. Each HDPE liner undergoes rigorous quality control tests, including:

Tensile Strength & Elongation Tests to ensure mechanical durability.

Puncture & Tear Resistance Tests for long-term reliability.

Chemical Resistance Testing to withstand harsh industrial environments.

UV Aging Tests to maintain integrity under sunlight exposure.

Our strict quality management ensures that every roll delivered meets international standards for performance and safety.

Installation Tips

Ensure the surface is clean, smooth, and free of sharp objects.

Overlap seams properly and use heat welding for secure joins.

Avoid excessive stretching during installation to prevent damage.

Regularly inspect installed liners for any punctures or wear.

Frequently Asked Questions (FAQ)

Q1: How long does an HDPE liner last?

A1: With proper installation, HDPE liners typically last 20–30 years.

Q2: Can the liner be customized?

A2: Yes, we provide custom thickness, width, and roll lengths for specific project requirements.

Q3: Is it safe for drinking water storage?

A3: Yes, our HDPE liners are non-toxic and safe for water storage applications.

Q4: Do you provide technical support for installation?

A4: Absolutely. Our team offers guidance, installation instructions, and on-site support if needed.

Q5: Can HDPE liners withstand extreme temperatures?

A5: Yes, they perform well under a wide temperature range, maintaining flexibility and strength.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Why Haoyang Stands Out

Haoyang Environmental Co., Ltd. is a source factory with years of experience supplying HDPE geomembranes globally. Our commitment to quality, technical innovation, and customer satisfaction has earned praise from clients across different industries. We combine premium materials, advanced production technology, and professional support to ensure that your waterproofing projects succeed.