150g Nonwoven Geotextile

1. Superior Filtration Performance: The 150g Nonwoven Geotextile filters soil particles while allowing water flow, ensuring soil stability in drainage and foundation works.

2. Efficient Separation Function: It separates soil layers or materials, preventing mixing and extending road lifespan in construction.

3. Enhanced Soil Reinforcement: With good tensile strength, it distributes loads evenly, improving soil bearing capacity.

4. Excellent Drainage Capability: Its porous structure enables fast water drainage, preventing soil saturation in waterlogged areas.

5. Reliable Protection: Protects underlying materials like geomembranes from soil - borne damage.

150g Nonwoven Geotextile - High - Performance Geosynthetic Solution

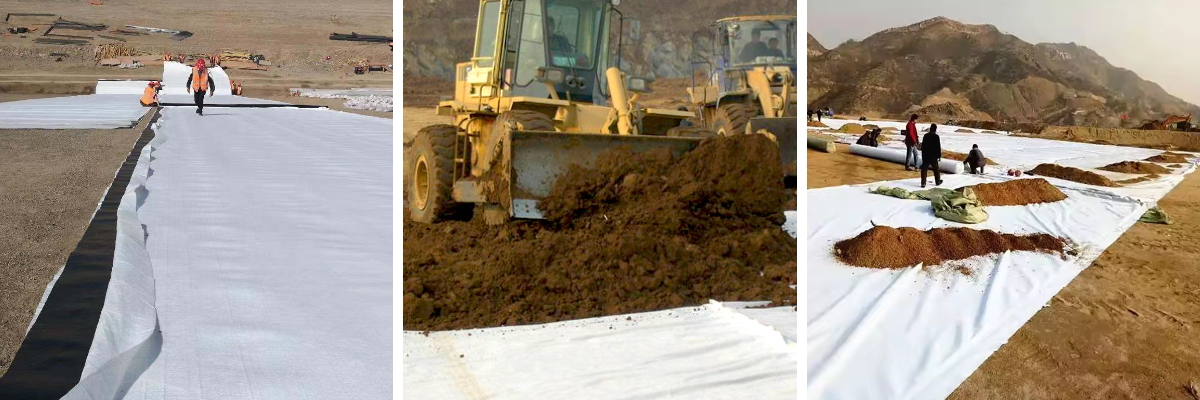

The 150g Nonwoven Geotextile is a top - tier geosynthetic material engineered to meet the diverse needs of modern construction, environmental protection, and landscaping projects. Backed by advanced manufacturing technology and strict quality control, it offers unparalleled performance and reliability. Whether crafted from PET long - filament or PP short - fiber, this geotextile provides distinct advantages tailored to different application requirements.

1. Key Advantages

(1) Superior Filtration

The 150g Nonwoven Geotextile features a carefully designed fiber structure that acts as an efficient filter. It allows water to permeate smoothly while effectively blocking soil particles, preventing soil erosion and maintaining soil stability. In drainage systems, it ensures water flows freely without carrying away fine soil, and in foundation works, it safeguards the integrity of the soil - water interaction.

(2) Efficient Separation

This geotextile serves as a reliable barrier between different soil layers or materials. In road construction, it separates the subgrade from the aggregate layer, stopping soil intrusion into the aggregate and significantly extending the road's service life. It maintains the distinct characteristics of each layer, enhancing the overall structural performance of the roadbed.

(3) Enhanced Reinforcement

With notable tensile strength, the 150g Nonwoven Geotextile reinforces soil structures effectively. When integrated into soil, it distributes loads evenly, improving the soil's bearing capacity and reducing the risk of settlement. For embankments and retaining walls, it provides additional support, ensuring long - term stability and safety.

(4) Rapid Drainage

Its porous nature enables rapid water flow, making it ideal for areas prone to waterlogging. In sports fields, it quickly drains excess water, allowing for uninterrupted use and protecting the turf. In garden landscapes, it prevents soil saturation, which can harm plant roots, ensuring a healthy growing environment for plants.

(5) Cost - Effective & Eco - Friendly

Lightweight and flexible, the geotextile is easy to handle and install, reducing labor costs and project timelines. Moreover, being made from recyclable materials, it aligns with sustainable construction practices, minimizing environmental impact while delivering high - performance results.

2. Product Specifications

Property | PET Long - Filament 150g Nonwoven Geotextile | PP Short - Fiber 150g Nonwoven Geotextile | Testing Standard |

Weight | 150g/m² | 150g/m² | ASTM D5261 |

Thickness | 1.6 - 2.0mm | 1.8 - 2.2mm | ASTM D5199 |

Tensile Strength (MD) | ≥10 kN/m | ≥8 kN/m | ISO 10319 |

Tensile Strength (TD) | ≥8 kN/m | ≥6 kN/m | ISO 10319 |

Elongation at Break (MD) | ≥20% | ≥25% | ISO 10319 |

Elongation at Break (TD) | ≥25% | ≥30% | ISO 10319 |

CBR Puncture Strength | ≥1.5 kN | ≥1.2 kN | ASTM D6241 |

Permeability | 0.08 - 0.2 cm/s | 0.1 - 0.3 cm/s | ASTM D4491 |

Chemical Resistance | Excellent resistance to alkalis | Good resistance to a wide range of chemicals | ASTM D543 |

UV Resistance | High - level resistance | Moderate resistance | ASTM G154 |

3. Wide - ranging Applications

(1) Construction Projects

Road Building: In highway construction, the 150g Nonwoven Geotextile, especially the PET long - filament variant with its high tensile strength, is used to separate the subgrade from the aggregate base course. This separation prevents the subgrade soil from mixing with the aggregate, improving the road's load - bearing capacity and reducing maintenance costs over time. For rural road projects, the more cost - effective PP short - fiber geotextile can be employed to achieve similar separation and reinforcement effects while keeping the budget in check.

Foundation Engineering: When constructing buildings, the geotextile is placed between the foundation soil and the base slab. It filters out soil particles during the construction process, ensuring a clean and stable foundation. In areas with soft soil, the geotextile reinforces the soil, helping to distribute the building's load evenly and prevent uneven settlement.

Tunnels & Retaining Walls: In tunnel construction, the geotextile provides drainage and protection for the tunnel lining. It prevents water from accumulating behind the lining, which could cause damage due to hydrostatic pressure. For retaining walls, it reinforces the soil mass, increasing the wall's stability and reducing the risk of soil failure. The PP short - fiber geotextile is often preferred for its good drainage properties in these applications.

(2) Environmental Protection

Landfills: At landfill sites, the 150g Nonwoven Geotextile is installed as a filtration layer above the leachate collection system. It stops soil particles from entering the collection pipes, ensuring the smooth flow of leachate for proper treatment. The PET long - filament geotextile's excellent chemical resistance makes it suitable for withstanding the potentially corrosive environment of leachate.

Erosion Control: On riverbanks, slopes, and coastal areas, the geotextile is used to control soil erosion. It is laid on the surface and secured in place, acting as a barrier against the erosive forces of water flow. In reforestation projects on eroded slopes, the geotextile helps retain soil moisture and provides a stable base for newly planted vegetation, promoting the restoration of the ecosystem.

(3) Landscaping

Gardens & Parks: In garden beds, the geotextile is placed beneath the soil to prevent weeds from growing through while still allowing water and nutrients to reach the plants' roots. It also helps with soil aeration and drainage, creating an ideal growing environment for flowers, shrubs, and trees. In park construction, it can be used in the construction of walkways and paths to separate the base materials from the soil, ensuring a stable and long - lasting surface.

Artificial Water Bodies: When building artificial lakes and ponds, the geotextile is laid under the pond liner as a protective layer. It prevents sharp rocks and soil debris from puncturing the liner, ensuring the water - tightness of the water body. Additionally, it can be used in the construction of fountains and waterfalls to manage water flow and prevent erosion of the surrounding soil.

Green Roofs: For green roof installations, the 150g Nonwoven Geotextile plays a crucial role in drainage and root protection. It allows excess water to drain away from the growing medium, preventing waterlogging that could damage the plants. At the same time, it stops the roots from penetrating into the building's roof structure, protecting the integrity of the roof while supporting the growth of a lush green roof garden.

For reliable, high - performance 150g Nonwoven Geotextile solutions, trust our products. Contact us today to discuss your project requirements and get a customized quote!