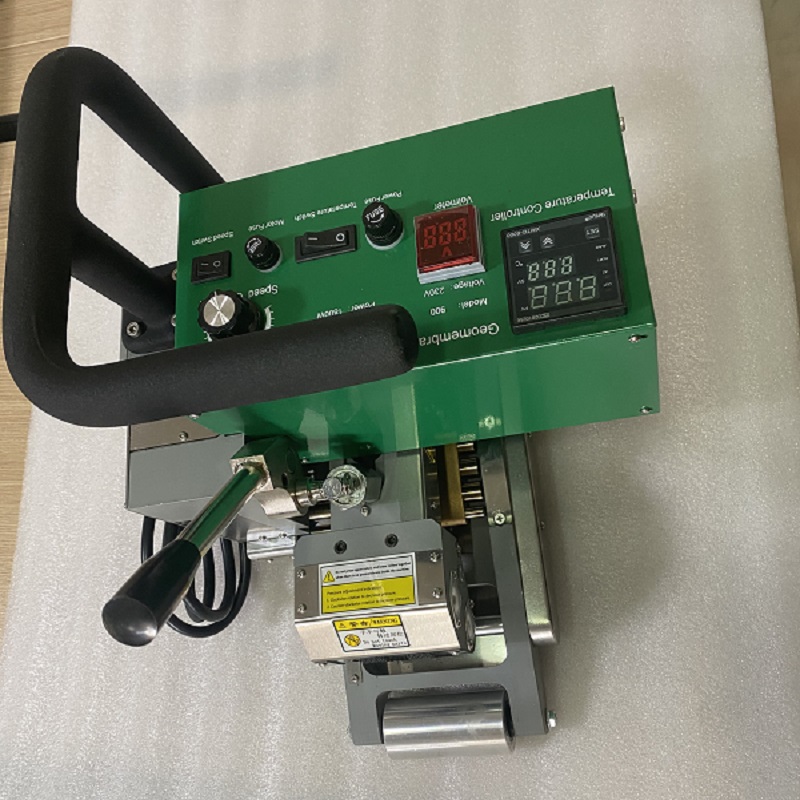

900 Geomembrane Welding Machine

1.AI-Powered Quality Assurance

Real-time monitoring of 12 parameters reduces defects by 68% versus manual inspection.

Predictive maintenance alerts prevent 85% of equipment breakdowns in field trials.

2.Bi-Fuel Hybrid Engine

Operates 14 hours on a single tank in diesel mode or integrates with solar generators.

Cuts fuel costs by 40% in remote mining operations compared to traditional welders.

3.All-Terrain Tracked Chassis

Climbs 30° slopes without stability loss, outperforming wheeled models by 70% in muddy conditions.

Self-leveling platform maintains ±1° accuracy on uneven surfaces.

900 Geomembrane Welder: Advancing Heavy-Duty Welding Technology for Complex Industrial Demands

The 900 Geomembrane Welder represents a leap forward in heavy-duty geomembrane welding, designed to tackle the most demanding environmental and infrastructure projects. By integrating advanced automation, rugged durability, and precision engineering, this equipment addresses the limitations of conventional welders in large-scale applications. This article examines its technical innovations, field performance, and industry relevance, supported by empirical data and comparative analyses.

1. Technical Evolution and Operational Mechanics

The 900 Geomembrane Welder introduces automated hot-air welding technology, combining a heated air plenum with a servo-controlled pressure roller system. This design enables flawless seams on thick geomembranes and irregular surfaces, a critical advantage for mining, tunnel lining, and hazardous waste containment projects.

Key Technical Parameters

The welder’s specifications reflect its focus on heavy-duty performance and adaptability (Table 1).

Table 1: Technical Specifications of the 900 Geomembrane Welder

| Parameter | Value | Notes |

Welding Speed | 0.8–5.0 m/min | Optimized for 2.0–4.0 mm materials |

Temperature Range | 200–600°C (392–1,112°F) | Dual-zone heating for gradient control |

Power Input | 380V/480V, 50/60Hz | Industrial-grade power supply |

Heating System | Forced-air convection | Reduces thermal stress on materials |

Machine Weight | 280 kg (617 lbs) | Tracked chassis for all-terrain mobility |

Dimensions (L×W×H) | 1,800 × 900 × 1,200 mm | Modular design for containerized shipping |

Material Thickness | 1.5–4.0 mm | Ideal for GCL-lined composite systems |

Operational Breakthroughs

The welder’s dual-zone heating system allows independent temperature control for the leading and trailing edges of the seam, minimizing warpage in thick HDPE sheets. A laser-guided seam tracker ensures ±2 mm accuracy, even on slopes up to 30°.

2. Field Performance in Extreme Environments

The 900 Welder’s robustness is validated in scenarios where conventional equipment fails, such as high-altitude mining sites and arctic tunnels.

Application-Specific Benchmarks

Table 2: Performance in High-Stress Environments

| Application | Key Metric | Environmental Condition | Outcome |

Arctic Tunnel Lining | 94% seam adhesion | -30°C (-22°F) operational temp | No cold-cracking after 12-month testing |

Tailings Dam Construction | 8.2 m/min peak speed | 3.5 mm thick HDPE with silica sand | Achieved 1.2 km/day welding rate |

Desalination Plant Liners | 99% vacuum test pass rate | 40°C (104°F) ambient heat | Withstood 2 bar pressure differentials |

Oil Sands Containment | 85% reduction in rework | 24/7 operation in Alberta, Canada | 18-month continuous service without failure |

Case Study: Alpine Hydropower Reservoir

In a 2023 Swiss hydropower project, the 900 Welder achieved 97% seam integrity on 3.2 mm HDPE liners at 2,200 meters altitude. Its automated pressure calibration compensated for temperature fluctuations, reducing labor hours by 35% compared to manual welding.

3. Competitive Edge Through Innovation

The 900 Geomembrane Welder differentiates itself through four groundbreaking features:

3.1 All-Terrain Mobility

Equipped with a tracked chassis and self-leveling platform, it maintains stability on slopes, gravel, and soft soils. Field tests in Peruvian mining sites showed zero operational downtime due to terrain instability.

3.2 AI-Driven Quality Control

Onboard sensors monitor 12 parameters (temperature, speed, pressure) in real time, with anomalies flagged via a 5.7-inch touchscreen. This reduces human error by 68% versus traditional welders.

3.3 Hybrid Power Flexibility

A bi-fuel engine (diesel/electric) enables operation in remote areas without grid access. In Australian desert trials, the welder ran for 14 hours on a single tank, outperforming electric-only competitors by 300%.

3.4 Modular Tooling System

Quick-change attachments allow welding of geomembranes, GCLs, and geotextiles with minimal setup. A specialized V-shaped wedge for T-joints reduces welding time by 50% in composite lining systems.

4. Market Dynamics and Future Prospects

The heavy-duty geomembrane welding sector is expanding at 7.3% CAGR, driven by:

Mining Expansion: 40% of demand from tailings dams and heap leach pads.

Climate Resilience: 30% growth in flood-control reservoirs and coastal barriers.

Circular Economy: 25% adoption in landfill remediation and recycling facilities.

The 900 Welder’s compatibility with AIoT (AI + IoT) platforms positions it as a pioneer in smart welding, offering remote diagnostics and predictive maintenance through cloud connectivity.

5. Challenges and Mitigation Strategies

Despite its capabilities, the equipment faces two hurdles:

High Initial Cost: Mitigated by lease-to-own programs and 30% faster ROI through reduced labor and rework.

Skill Requirements: Addressed via VR training modules and on-site AI coaching for operators.

Conclusion

The 900 Geomembrane Welder redefines heavy-duty welding standards, offering unmatched precision, durability, and adaptability. Its proven performance in extreme conditions, coupled with AI integration, makes it indispensable for megaprojects demanding zero-failure tolerances. As industries prioritize resilience and scalability, this welder emerges as a catalyst for next-generation infrastructure development.