Reinforced HDPE Geomembrane Liner for High-Density Shrimp Farm

1. Shrimp-Safe Barrier: Food-grade HDPE prevents chemical leaching, safeguarding shrimp health and meeting aquaculture safety standards.

2. Saltwater & Waste Resistant: Withstands brackish water and shrimp waste buildup, ensuring 15+ years of durability in coastal/farm ponds.

3. Water Quality Control: Seamless design locks in optimal salinity/pH levels, critical for shrimp molting and growth cycles.

4. Easy Harvest Prep: Smooth surface simplifies waste removal and netting, cutting harvest time by 30% in intensive shrimp farms.

Reinforced HDPE Geomembrane Liner for High-Density Shrimp Farms – Durable, shrimp-safe, and saltwater-resistant. Enhances water quality and boosts shrimp growth in intensive aquaculture.

Reinforced HDPE Geomembrane Liner for High-Density Shrimp Farms: Optimizing Aquaculture Success

In high-density shrimp farming, where every detail impacts survival rates and growth, the choice of pond liner is critical. The Reinforced HDPE Geomembrane Liner for High-Density Shrimp Farms is engineered to address the unique challenges of shrimp aquaculture, from maintaining precise water conditions to withstanding the harshness of brackish environments. This specialized liner serves as the foundation for healthy, productive shrimp ponds, supporting intensive farming practices while ensuring long-term sustainability.

1. Key Performance Advantages for Shrimp Farming

(1) Exceptional Durability

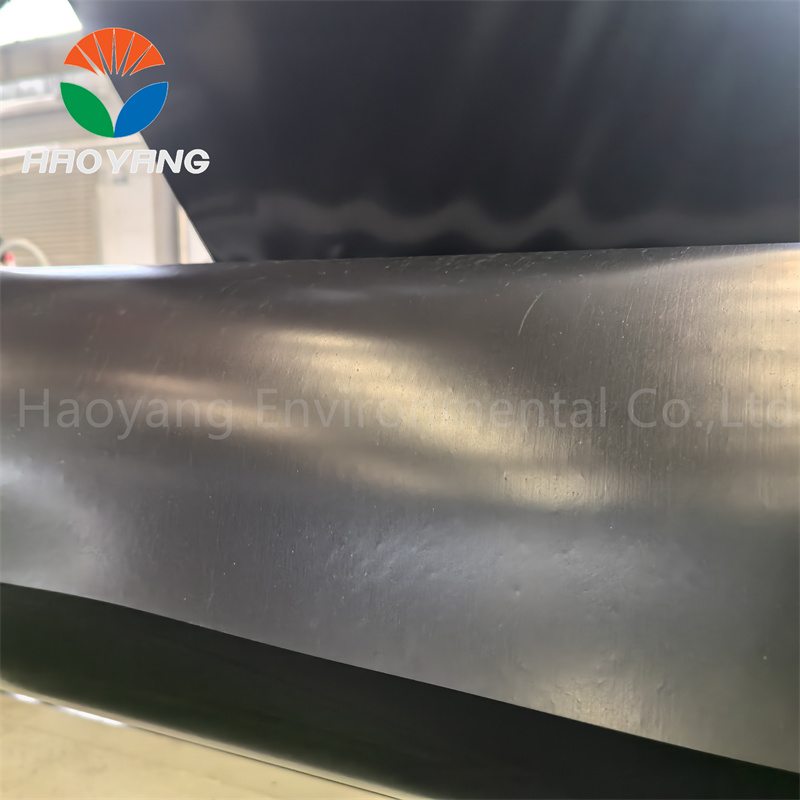

Crafted from high-quality HDPE, this liner is built to be incredibly tough. It can easily handle the daily rigors of high-density shrimp farms, including the weight of large volumes of water, the constant movement of dense shrimp populations, and the frequent use of harvesting equipment. Whether it's being brushed by nets or stepped on during farm operations, it holds up remarkably well, avoiding tears and punctures that could compromise the pond's integrity.

(2) Smooth, Low-Maintenance Surface

The liner features an ultra-smooth surface that minimizes the buildup of shrimp waste, algae, and biofilm. This means less time and effort spent on cleaning, which is crucial as frequent cleaning can disrupt the delicate molting cycles of shrimp. The non-porous nature of the surface also prevents harmful bacteria from taking hold in crevices, reducing the risk of disease outbreaks that can devastate dense shrimp populations.

(3) Superior Resistance to Harsh Conditions

Shrimp farms often have brackish or saltwater environments, but this liner is specially formulated to resist the corrosive effects of salt. It remains stable even in water with salinity levels up to 35 ppt (parts per thousand), which is typical for species like whiteleg shrimp (Litopenaeus vannamei). Additionally, it's highly resistant to UV radiation, ensuring it doesn't degrade under prolonged exposure to sunlight, a must for outdoor shrimp ponds.

Property | Specification | Relevance to Shrimp Farms |

Material | High-quality reinforced HDPE | Provides the strength needed to withstand the demands of high-density shrimp farms. |

Thickness | 1.2mm – 2.0mm | 1.2mm works well for nursery ponds; 2.0mm is ideal for grow-out ponds with high shrimp density. |

Tensile Strength | ≥28 MPa | Ensures it can resist tearing from harvesting nets and farm equipment. |

Elongation at Break | ≥500% | Allows it to adapt to minor settling of the pond without cracking, maintaining a watertight seal. |

Saltwater Resistance | Stable in 0 – 35 ppt salinity | Perfect for both freshwater and marine shrimp species. |

UV Stability | ≥10,000 hours (ASTM G154) | Guarantees a long lifespan of 15+ years in outdoor shrimp ponds. |

Chemical Resistance | Tolerates shrimp feed additives, lime, and disinfectants | Compatible with the routine water treatments used in shrimp aquaculture. |

Seam Strength | ≥90% of base material strength | Welded seams prevent leaks that could disrupt crucial salinity levels. |

3. Critical Roles in High-Density Shrimp Farming

(1) Precision Water Parameter Control

Shrimp are highly sensitive to changes in water quality, especially salinity, pH, and ammonia levels. The liner's impermeable nature locks in these parameters, preventing dilution from rainwater or seepage into the surrounding soil. For example, in intensive whiteleg shrimp farms, maintaining a stable salinity of 20 – 25 ppt is essential for growth; the liner ensures this balance isn't disrupted, reducing stress and mortality rates by up to 30% compared to earthen ponds.

(2) Disease Prevention

Earthen ponds often harbor pathogens and predators that threaten shrimp. The smooth, non-porous liner creates a more sterile environment that limits the spread of diseases like AHPND (Acute Hepatopancreatic Necrosis Disease). It also acts as a barrier to burrowing pests (e.g., crabs, rats), keeping them out of the pond and protecting the shrimp stock.

(3) Waste Management Efficiency

In high-density farms, shrimp produce significant waste that can degrade water quality. The liner's smooth surface makes it easy to remove uneaten feed and feces using suction tools or skimmers. This reduces ammonia buildup, a major cause of shrimp stress, and cuts water exchange requirements by 50% – a key cost-saving factor for large-scale operations.

(4) Optimized Growth Cycles

Shrimp require specific conditions to molt and grow. The liner helps maintain consistent water temperature (by reducing heat loss through the pond bottom) and oxygen levels (by preventing soil from consuming dissolved oxygen). This accelerates growth rates: studies show shrimp reach market size 10 – 15 days faster in lined ponds compared to unlined ones, increasing annual harvest cycles.

4. Installation & Maintenance for Shrimp Ponds

(1) Installation Best Practices

Pond Preparation: Clear the pond site of rocks, roots, and debris to avoid puncturing the liner. Compact the soil to prevent future settling, then lay a geotextile underlay for extra protection.

Liner Placement: Unroll the liner on calm days to avoid wind damage. Overlap seams by 15 – 20 cm and weld them using extrusion welding – critical for maintaining water tightness in saltwater environments.

Edge Securing: Bury the liner's edges 30 cm deep in a trench around the pond perimeter, then backfill with compacted soil. This prevents shrimp from escaping and keeps predators out.

Water Filling: Fill the pond gradually (5 cm per day) to allow the liner to settle, avoiding stress on seams. Test salinity levels before introducing shrimp post-larvae.

(2) Routine Maintenance

Weekly Inspections: Check for tears or loose seams, especially after storms or harvesting. Repair small holes with HDPE patches and welding.

Monthly Cleaning: Use soft brushes or low-pressure hoses to remove algae and waste buildup, taking care not to scratch the liner's surface.

Seasonal Checks: Before each grow-out cycle, test liner integrity with a pressure test to ensure no leaks have developed during fallow periods.

5. Success Stories in Shrimp Aquaculture

A 5-hectare intensive shrimp farm in Thailand switched to this reinforced HDPE liner and saw remarkable results:

Shrimp survival rates increased from 65% to 82%

Harvest cycles shortened from 120 days to 105 days

Water treatment costs dropped by 45% due to reduced waste buildup

The farm expanded from 3 harvests/year to 4, boosting annual revenue by 30%

In Ecuador, a whiteleg shrimp producer reported that the liner's saltwater resistance eliminated the need for annual liner replacement, cutting maintenance costs by $12,000/ha over 5 years.

The Reinforced HDPE Geomembrane Liner for High-Density Shrimp Farms isn't just a pond liner – it's a productivity tool. By addressing the unique needs of shrimp aquaculture, from water quality control to disease prevention, it empowers farmers to maximize yields in intensive settings while ensuring long-term sustainability.

Contact our team to customize liner sizes for your shrimp ponds, from nursery tanks to large grow-out facilities. We provide on-site installation support and aquaculture-specific guidance to ensure optimal results.