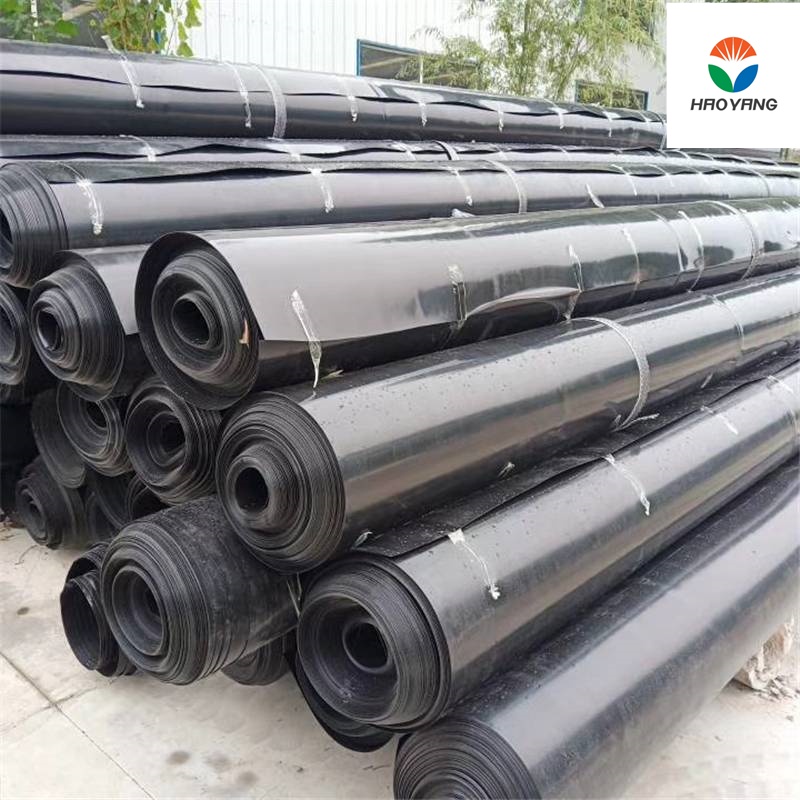

Ultraviolet-Resistant 1mm HDPE Geomembrane

1. Strong UV resistance

By adding special UV-resistant additives, it can be used for long-term exposure to outdoor sunlight and effectively resist UV-induced aging.

2. Excellent anti-seepage effect

The 1mm thick HDPE material has high density and stable molecular structure, which can form a complete and sealed anti-seepage layer, effectively blocking water.

3. Good physical strength

It has excellent tensile strength and puncture resistance. During construction, it is unlikely to be damaged by external forces.

4. Economical, practical and easy to install

The material is lightweight, and 1mm thick is convenient for cutting and welding, with high construction efficiency; at the same time.

I. Product Overview

1mm HDPE Geomembrane, which is a 1-millimeter thick high-density polyethylene geotextile membrane, is a widely used material in various anti-seepage and waterproofing projects. It is made from high-density polyethylene as the main raw material through advanced production processes and possesses excellent comprehensive properties.

The HDPE geomembrane itself has high strength, corrosion resistance, and low-temperature resistance, and ultraviolet resistance (Ultraviolet-Resistant) is one of its prominent advantages. In outdoor engineering applications, the material is exposed to sunlight for a long time, and ultraviolet radiation accelerates the aging of the material and reduces its performance and lifespan. This 1mm HDPE geotextile membrane, through special formulations and processes, adds efficient ultraviolet-resistant additives, which can effectively resist ultraviolet erosion and maintain the stability of the material's performance. This characteristic enables it to play a crucial role in open-air water conservancy projects, landfill sites, landscape ponds, and other projects, ensuring the long-term safety and stability of the projects.

II. Physical and Chemical Properties

(1) Physical Properties

The 1mm HDPE geomembrane exhibits outstanding performance in physical properties. From the perspective of tensile properties, its tensile yield strength (longitudinal and transverse) is ≥ 13N/mm, and its tensile breaking strength (longitudinal and transverse) is ≥ 20N/mm. The yield elongation rate (longitudinal and transverse) is ≥ 11%, and the breaking elongation rate (longitudinal and transverse) is ≥ 600%. In terms of puncture resistance, its value is ≥ 240N. The right-angle tear strength (longitudinal and transverse) is ≥ 115N, indicating that the material has a good resistance when subjected to tearing force, reducing the risk of damage caused by external force tearing in actual use.

| Performance | Numerical value |

| Tensile Yield Strength (Longitudinal and Transverse)(N/mm) | ≥13 |

| Tensile Break Strength (Longitudinal and Transverse)(N/mm) | ≥20 |

| Yield Elongation (Longitudinal, Transverse)(%) | ≥11 |

| Tensile Elongation at Break (Longitudinal and Transverse)(%) | ≥600 |

| Right-angle Tear Strength (Longitudinal and Transverse)(N) | ≥115 |

| Puncture resistance(N) | ≥240 |

(II) Chemical Properties

In terms of chemical properties, the 1mm HDPE geotextile membrane exhibits excellent resistance to acids and alkalis as well as chemical corrosion. It does not undergo chemical reactions that would deteriorate the material's performance. In the construction of wastewater treatment ponds in the chemical industry, various strong acids and strong bases are often encountered. The 1mm HDPE geotextile membrane can effectively resist the erosion of these chemical substances, maintaining its anti-seepage performance over a long period and ensuring that the wastewater does not seep into the ground, thus preventing soil and groundwater from being contaminated.

At the same time, it also has good tolerance to various chemical substances such as organic solvents and salt solutions. It is widely used in industries and environmental protection fields that have high requirements for chemical stability, thereby ensuring the safety of the project and the sustainability of the environment.

III. Application Areas

(1) Water Conservancy Engineering

A 1mm HDPE geotextile membrane is laid on the bottom of the reservoir and the inner surface of the dam, which can effectively prevent water leakage and reduce unnecessary loss of water resources, ensuring the water storage capacity of the reservoir. At the same time, it can avoid potential safety hazards such as dam collapse and pipe seepage caused by leakage, maintaining the stability of the dam structure and extending the service life of the project.

(2) Environmental Protection Engineering

In landfill sites, the geotextile membrane is laid on the bottom and four walls of the landfill, acting like a huge "container", separating the garbage from the surrounding soil and groundwater. The leachate produced by the decomposition of garbage contains a large amount of harmful substances. If it seeps into the ground, it will seriously pollute the soil and groundwater resources. The 1mm HDPE geotextile membrane, with its extremely low permeability coefficient, reduces the risk of environmental pollution. This type of geotextile membrane is also commonly used in sewage treatment plants' water tanks and regulating ponds to ensure that the sewage does not leak during the treatment process and maintain the ecological balance of the surrounding environment.

(3) Agricultural Field

When laid in water channels and storage tanks of irrigation systems, it can significantly reduce water leakage and evaporation loss, allowing the limited water resources to be used more precisely for crop irrigation, improving irrigation efficiency, and promoting crop growth. This is particularly significant in areas with drought and water shortage, helping to alleviate water resource shortages and ensuring agricultural production, providing support for the sustainable development of agriculture.

(4) Aquaculture

When laid in fish ponds, shrimp ponds, and other breeding pools, the geotextile membrane can effectively prevent water body leakage, maintain stable water levels, and reduce water replenishment costs. At the same time, the geotextile membrane can prevent heavy metals, harmful substances, etc. from seeping into the breeding water body from underground, protecting the water quality of the breeding area, creating a healthy growth environment for fish and shrimp, and increasing breeding yield and quality.

(5) Mining Field

Tailings dams are places where mining waste is stored. If no anti-seepage measures are taken, the harmful substances such as heavy metals and chemical agents in the tailings will leak once, causing serious pollution to the surrounding soil and water bodies. In the heap leaching ponds during the extraction of metals from ore, using the geotextile membrane can prevent the leakage of chemical leaching liquid, reducing the risk of environmental pollution, and ensuring the environmental protection and sustainability of mining production.

IV. Successful Cases Abroad

(1) Cambodia River Management Project

In the local river management project, there were problems such as water seepage and erosion damaging the stability of the river course. This project used 1mm HDPE geotextile membrane. Its anti-ultraviolet performance effectively delayed material aging under high-temperature exposure and maintained the stability of the material's mechanical properties. The extremely low permeability coefficient effectively controlled the seepage of river water. After one year of operation monitoring, the seepage volume was ≤ 0.1m³/d, far exceeding the design requirements, ensuring the rational utilization of river water resources, maintaining the stability of the surrounding ecosystem, and preventing soil salinization caused by river water seepage.

(2) Provincial River Project in Vietnam

The provincial river project in Vietnam has extremely high requirements for anti-seepage, with a required permeability coefficient of ≤ 2.0×10^-13 cm/s. In the project, the geotextile membrane withstood the tests of the complex geological conditions and water flow erosion in the local area, and passed the strict testing of the local third-party testing institution. Due to its reliable performance, it became the designated anti-seepage material for this project, ensuring the long-term stable operation of the river project, preventing the pollution of underground water resources by river water, and providing a guarantee for the water safety of local residents.

(3) A Foreign Garbage Landfill Project

A foreign garbage landfill project is located in a densely populated area with abundant underground water resources. This landfill project used 1mm HDPE geotextile membrane as the anti-seepage material, which was laid at the bottom and four walls of the landfill site, effectively blocking the seepage of garbage leachate. After long-term monitoring, the groundwater quality in the surrounding area was not polluted, and the high strength and corrosion resistance of the geotextile membrane ensured its good anti-seepage performance under the heavy pressure of garbage and chemical erosion, extending the service life of the landfill site.

V. Summary

The 1mm UV-resistant HDPE geotextile membrane, with its outstanding physical and chemical properties, has demonstrated extraordinary value in numerous fields. From the efficient utilization and protection of water resources in water conservancy projects, to the strict barrier against pollutants in environmental protection projects; from assisting in water-saving irrigation in the agricultural sector, to ensuring production and environmental safety in the aquaculture and mining industries, its application scope is extensive, covering multiple important aspects of the national economy.

In many successful cases abroad, the 1mm UV-resistant HDPE geomembrane has withstood the tests of different climates, geological conditions, and engineering requirements, providing reliable guarantees for local infrastructure construction, environmental protection, and resource development.

Looking forward to the future, as the requirements for engineering quality and environmental protection in various industries continue to rise, the 1mm UV-resistant HDPE geotextile membrane is expected to be applied in more emerging fields, and its performance will also be continuously optimized through technological innovation, continuously contributing to global engineering construction and environmental protection, and becoming an important supporting material for promoting industry development and sustainable progress.