40 mil HDPE Geomembrane for Mining

1. Extremely strong in seepage prevention, with a high seepage coefficient, it can effectively prevent the leakage of pollutants from the mine site and protect the water resources of South Africa.

2. Outstanding resistance to chemical corrosion, capable of resisting the erosion of mine acids and alkalis as well as acidic mine drainage.

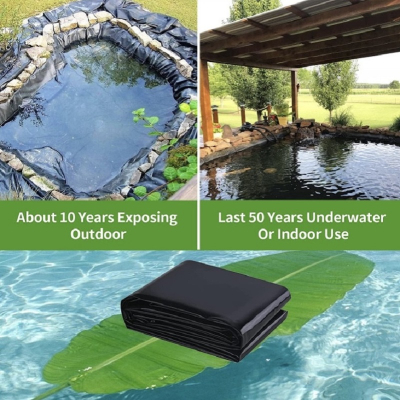

3. Excellent UV resistance and weather resistance, suitable for the diverse climates of South Africa, with stable performance even when exposed for a long time.

4. High tensile strength and good flexibility, easy to construct and able to adapt to the complex terrain and subsidence of the mine site.

Chapter 1: Overview of HDPE Geomembrane

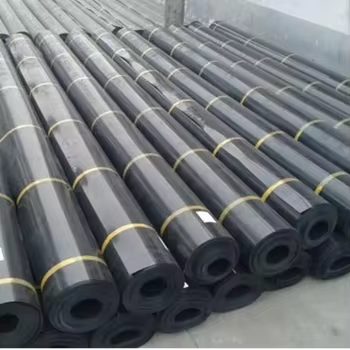

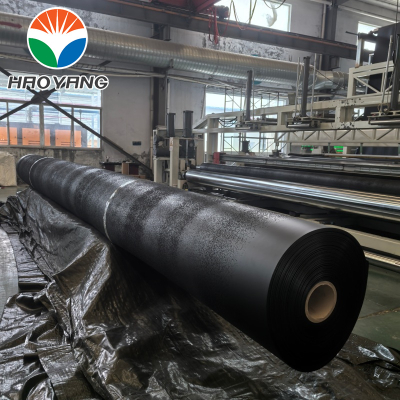

HDPE geomembrane is a premium impermeable liner crafted from 97.5% virgin high-density polyethylene resin, blended with 2.5% carbon black, antioxidants, and UV stabilizers . Compliant with SANS and GRI GM 13 standards , it boasts ultra-low permeability (1×10⁻¹⁷ cm/s) and 40–60-year lifespan . Critical for South Africa’s mining sector, it curbs contamination, conserves water, and aligns with national environmental regulations .

Chapter 2: Physical Performance Indicators

Thickness | mm | 1.00 | 2.00 |

Density | g/cc | ≥0.940 | ≥0.940 |

Yield Strength | kN/m | 15 | 29 |

Break Strength | kN/m | 27 | 53 |

Break Elongation | % | 700 | 700 |

Tear Resistance | N | 125 | 249 |

Puncture Resistance | N | 320 | 640 |

Carbon Black Content | % | 2.0–3.0 | 2.0–3.0 |

Chapter 3: Chemical Performance Indicators

Performance Indicator | Performance Description | Applicable Mining Chemicals |

Chemical Inertness | Resists 99% of acids (pH 2–12) and hydrocarbons | Sulfuric acid, heavy metal solutions |

Oxidative Induction Time | ≥100min (standard); ≥400min (high pressure) | Oxidizing mine wastewater |

UV Resistance | ≥50% OIT retained after 1600h exposure | Solar radiation in exposed mines |

Oven Aging Resistance | ≥80% property retention | High-temperature mining zones |

Acid Mine Drainage Resistance | No degradation after 24-month immersion | Acidic tailings leachate |

Chapter 4: Factors Influencing Prices

1.Raw Material Costs: Tied to global oil prices, HDPE resin fluctuations directly impact production costs—accounting for 60–70% of final pricing .

2.Thickness & Specifications: 3.0mm liners cost 3–4x more than 0.75mm variants due to higher resin usage and enhanced performance .

3.Certification Compliance: Meeting SANS 1526 and GRI standards adds 10–15% to costs via rigorous testing .

4.Logistics & Import Fees: South Africa’s 60 forces imports, with shipping and tariffs increasing prices by 22% vs. Asian markets .

5.Order Scale: Bulk orders (≥10,000㎡) secure 5–8% discounts, while small batches bear higher unit costs .

Chapter 5: Applications in Mining

1.Tailings Pond Lining: Mandated by NEMA Regulations 632–636 , it prevents leachate seepage and recovers 95L water/ton tailings .

2.Heap Leach Pad Containment: Isolates cyanide-based lixiviants in gold/platinum mines, reducing soil contamination .

3.Acid Mine Drainage Control: Lines collection ditches to neutralize acidic runoff before treatment .

4.Waste Rock Dump Lining: Blocks heavy metal migration into groundwater—critical for water-scarce regions .

5.Evaporation Pond Lining: Reduces water loss by 95% in arid mining areas like Northern Cape .

6.Mine Closure Remediation: Restores decommissioned sites by limiting pollutant spread and aiding vegetation regrowth .

Chapter 6: Haoyang Environment’s Projects

1.Gauteng Platinum Tailings Project: Supplied 18,000㎡ 2.0mm textured HDPE liners for a composite barrier system. Compliant with SANS 1526, it achieved zero leakage and 92% water recovery over 2 years .

2.KwaZulu-Natal Coal Mine AMD Control: Installed 12,500㎡ acid-resistant liners in leachate collection ponds. Reduced heavy metal seepage by 99% and passed DWS audits .

3.Northern Cape Gold Mine Closure: Provided 25,000㎡ UV-stabilized liners for waste rock dumps. Supported ecosystem restoration and met mine rehabilitation deadlines .

Chapter 7: Market Shortcomings and Future Trends

Shortcomings

1.Cost Barriers: Premium pricing deters small-scale mines, despite long-term savings .

2.Skill Gaps: Improper installation by untrained labor causes 30% of premature failures .

3.Local Capacity Deficit: 60% of demand relies on imports, leading to supply delays .

Future Trends

1.Sustainable Innovation: Bio-based HDPE and recycled variants will gain traction, cutting costs by 22% .

2.Regulatory Push: Stricter DWS mandates will boost adoption in existing mines .

3.Regional Localization: On-site production facilities to reduce import reliance .

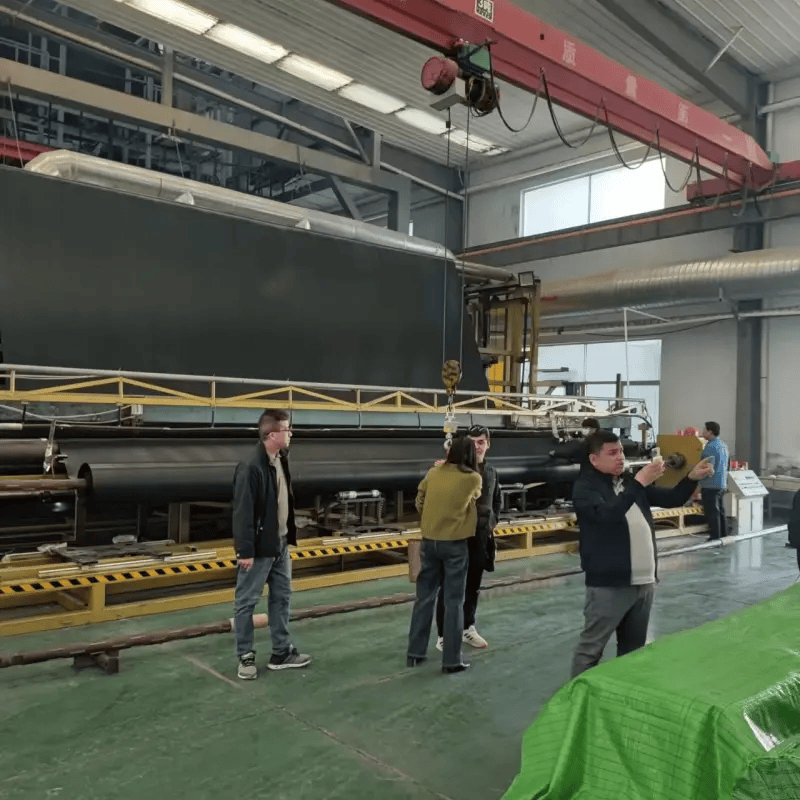

Chapter 8: Haoyang Environment’s Production & Sales Advantages

Haoyang uses three-layer co-extrusion tech to meet SANS 1526 standards . Its in-house lab ensures consistent quality, while bulk production cuts resin costs by 12%. The sales team offers on-site installation training—addressing local skill gaps—and provides 5-year post-sales support, building trust in mining clients.