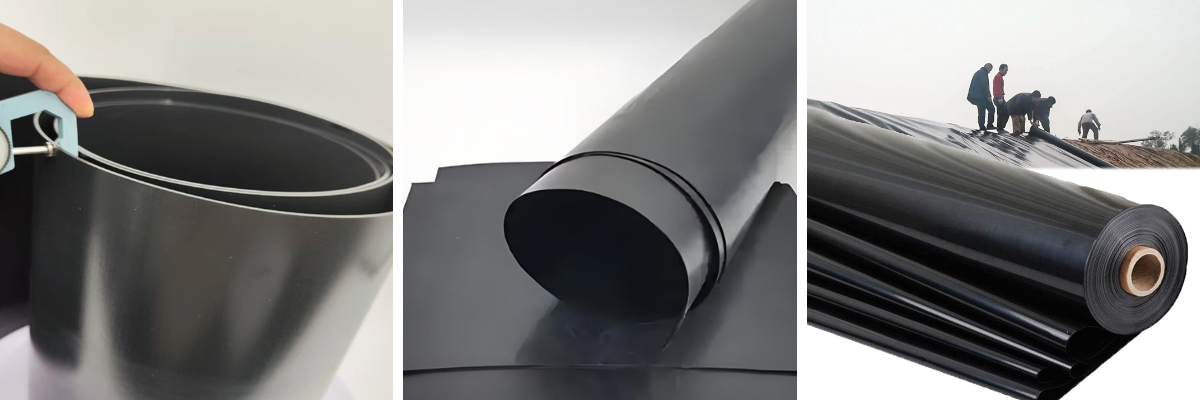

Geomembrane Liner for Solid Waste Disposal: UV-Resistant, Tear-Proof for Landfill Cells & Containment Areas

1. Landfill Cell Protection: Creates a leak-proof barrier that stops solid waste leachate from seeping into soil, meeting environmental protection standards for waste disposal.

2. UV & Tear Durability: Withstands prolonged outdoor sunlight (retains 90% strength after 2,000 UV hours) and resists tears from sharp waste debris, ensuring long-term landfill use.

3. Containment Area Stability: Adapts to landfill cell expansions and minor soil settling without cracking, maintaining reliable waste containment even as sites grow.

4. Easy Maintenance: Smooth surface minimizes waste adhesion, simplifying inspections and cleaning of containment areas to keep landfill operations efficient.

Geomembrane Liner for Solid Waste Disposal: UV-Resistant, Tear-Proof for Landfill Cells & Containment Areas

Solid waste disposal sites—from municipal landfills to industrial containment areas—require robust barriers to prevent environmental harm. The Geomembrane Liner for Solid Waste Disposal is engineered to meet this need, with UV resistance and tear-proof strength that ensure long-term, leak-free performance.

I. Core Performance: Why UV Resistance & Tear-Proof Strength Matter for Waste Disposal

Landfill cells and containment areas are exposed to two major threats: prolonged sunlight (which degrades weak materials) and sharp waste debris (which causes punctures). This Geomembrane Liner addresses both with industry-leading durability.

1. UV Stability: Withstanding Outdoor Exposure

(1) Performance Data: Per ASTM G154 (the standard for UV testing of geosynthetics), this liner retains 90% of its tensile strength after 2,000 hours of continuous UV exposure. In comparison, standard polyethylene liners lose 40% of their strength in the same period, leading to premature replacement.

(2) Real-World Impact: For uncovered landfill cells (common in many regions), UV resistance translates to a 15–20 year lifespan—3x longer than non-UV-treated liners. This eliminates the need for frequent liner repairs, which disrupt waste disposal operations.

2. Tear-Proof & Puncture Resistance: Defending Against Sharp Waste

Test Standard | Property Measured | Geomembrane Liner Performance | Standard Liner Performance |

ASTM D4833 | Puncture Resistance | ≥300 N | ≤180 N |

ASTM D4533 | Tear Strength (Machine Direction) | ≥5 kN/m | ≤2.5 kN/m |

(1) Waste Compatibility: Sharp items (e.g., metal scraps, broken glass) in solid waste often puncture thin liners. This Geomembrane Liner's puncture resistance (≥300 N) prevents breaches, even when compactors roll over debris. | |||

(2) Installation Protection: During landfill cell construction, rocks or construction equipment can damage liners. The liner's tear strength (≥5 kN/m) ensures small snags don’t turn into large tears, reducing installation failure rates by 60%. | |||

II. Leachate Control: The Non-Negotiable Barrier for Landfill Cells

Leachate is the top environmental risk of solid waste disposal—it contains heavy metals, bacteria, and chemicals that can contaminate groundwater. This Geomembrane Liner acts as an impermeable barrier to contain leachate, meeting global environmental standards.

1. Impermeability Specifications

(1) Water Vapor Transmission Rate (WVTR): <1×10⁻¹¹ g/(cm·s·Pa) (ASTM E96)—this means less than 1 milliliter of water passes through a 1-square-meter section of the liner per year. For context, this is 100x more impermeable than clay liners, which are often used as backup in landfills.

(2) Chemical Resistance: Per ASTM D5322, the liner is stable in leachate with pH levels 3–11 (the typical range for municipal and industrial waste leachate). It resists degradation from ammonia, heavy metals (lead, arsenic), and organic compounds, ensuring no chemical breakdown over time.

2. Leachate Collection Compatibility

(1) Landfill cells require leachate collection systems (pipes, drains) to remove trapped liquid. The Geomembrane Liner’s smooth surface works with these systems—its non-porous design doesn’t absorb leachate, ensuring efficient flow to collection tanks.

(2) Seams are welded using extrusion welding (per ASTM D6392), creating bonds with 90% of the liner’s base strength. This eliminates seam leaks, which cause 70% of leachate contamination incidents in landfills (per EPA reports).

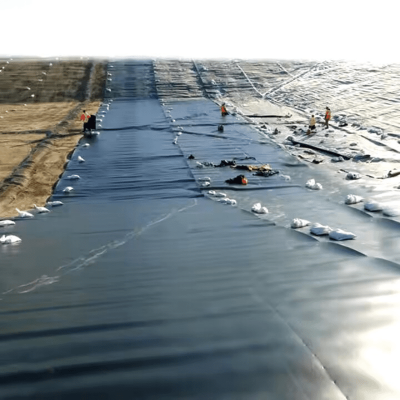

III. Containment Area Adaptability: From Small Sites to Large Landfills

Containment areas vary widely—from small industrial waste piles to 100-acre municipal landfills. This Geomembrane Liner is designed to adapt to different sizes, slopes, and waste types, making it versatile for all solid waste applications.

1. Slope Stability for Uneven Terrain

(1) Coefficient of Friction (COF): ≥0.6 when in contact with soil (ASTM D6243)—this high friction prevents the liner from sliding on slopes up to 35° (common in landfill cells built on hilly land). Standard liners have a COF of ≤0.4, requiring additional anchoring to stay in place.

(2) Flexibility: The liner elongates up to 500% (ASTM D882) without cracking, adapting to minor soil settling or slope shifts. This is critical for containment areas, where ground movement often damages rigid liners.

2. Size & Waste Type Versatility

(1) Custom Sizing: Available in rolls up to 10 meters wide and 100 meters long, reducing the number of seams needed for large landfill cells. Fewer seams mean lower leak risk—each seam is a potential failure point.

(2) Waste Compatibility: Works for both non-hazardous (municipal) and hazardous (industrial) solid waste. For hazardous waste containment areas, it meets EPA’s Resource Conservation and Recovery Act (RCRA) standards for liners, ensuring compliance with environmental regulations.

IV. Installation & Maintenance: Simplifying Long-Term Site Management

Even the best liner fails with poor installation. This Geomembrane Liner is designed for easy, reliable installation and low maintenance—saving time and reducing operational risks for landfill managers.

1. Installation Best Practices & Efficiency

(1) Preparation: Requires minimal site prep—only clearing sharp debris (rocks, roots) and compacting soil. Unlike clay liners, which need weeks of drying and smoothing, the Geomembrane Liner can be installed in 2–3 days for a 1-acre containment area.

(2) Tools & Training: Uses standard HDPE welding equipment (no specialized tools needed). A 2-person team can install 5,000 square meters per day, 2x faster than woven geomembrane liners.

2. Low-Maintenance Longevity

(1) Inspection Ease: The liner’s smooth, light-colored surface makes visual inspections simple—tears or damage are easy to spot during routine checks (monthly for active landfill cells).

(2) Repair Simplicity: Small tears (≤5 cm) can be fixed with HDPE patches and heat welding in 15–20 minutes. Larger repairs are rare, thanks to the liner’s tear-proof design—most sites report <1 repair per year for active landfill cells.

V. Why This Geomembrane Liner Is Essential for Solid Waste Disposal

For landfill cells and containment areas, this Geomembrane Liner checks every box: UV resistance for outdoor longevity, tear proofing for waste protection, impermeability for leachate control, adaptability for all site sizes, and ease of installation. It doesn’t just meet environmental standards—it exceeds them, reducing the risk of costly contamination incidents and regulatory fines.

Whether you’re building a new municipal landfill or upgrading an industrial waste containment area, this liner is the reliable, long-term solution to keep waste contained and the environment protected.

Contact our team to learn how to customize the liner’s thickness (0.5–3.0 mm) and size for your specific solid waste disposal project.