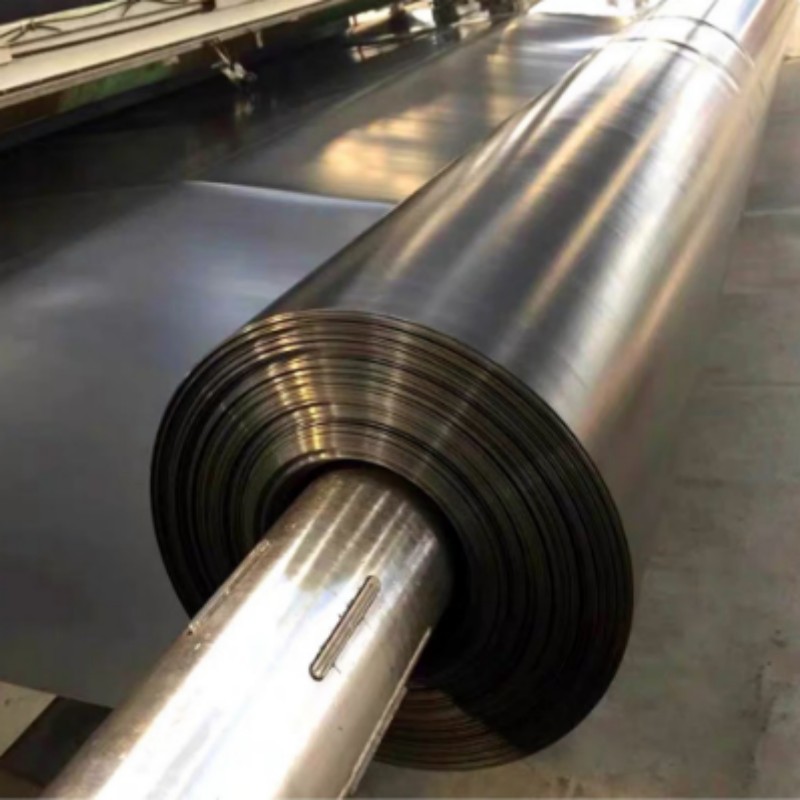

10m Wide HDPE Geomembrane: Ideal for Large-Scale Applications

1.Fewer Seams – 10m width reduces welds and leakage risks.

2.Faster Installation – Covers large areas quickly to save time.

3.Lower Labor Costs – Less welding and manpower required.

4.High Durability – Excellent UV, chemical, and aging resistance.

5.Smooth Coverage – Wide sheets ensure uniform, stable lining.

6.Perfect for Large Projects – Ideal for reservoirs, landfills, and mining applications.

As large civil engineering and environmental protection projects continue to expand in scale, the need for efficient, reliable, and long-lasting waterproofing solutions has become more important than ever. From municipal landfills and industrial containment facilities to irrigation reservoirs and mining sites, project owners are constantly searching for materials that can cover broad areas quickly while maintaining strict environmental standards. One solution that has gained significant attention in recent years is the 10-meter-wide HDPE geomembrane.

Compared with standard-width liners, the 10m wide HDPE geomembrane offers clear advantages in installation efficiency, seam reduction, structural stability, and overall project cost. Its performance in harsh conditions makes it a preferred choice for engineering teams seeking both durability and long-term environmental security.

Why Wide-Width Geomembranes Are Transforming the Industry

Traditional geomembranes typically come in widths of 5–7 meters. While these sizes are suitable for small- and medium-scale projects, they require more sheet overlaps and welding work when used in large sites. Each additional seam introduces potential weak points and increases installation time.

The 10m wide HDPE geomembrane dramatically changes this dynamic. By offering nearly double the coverage per roll, it reduces the number of seams, simplifies construction logistics, and brings greater reliability to the entire lining system. This makes it particularly valuable for projects where surface areas extend into tens or even hundreds of thousands of square meters.

For engineers, contractors, and project investors, these benefits translate directly into greater operational efficiency and long-term stability.

Advantages of 10m Wide HDPE Geomembrane

1. Reduced Seams and Higher Anti-Leak Integrity

One of the most significant benefits of the 10m width is the reduction in the number of seams across the installation area. Fewer seams mean fewer welds, fewer tests, and fewer potential weak points. Seam-related failures are a common cause of leakage, so minimizing them greatly improves the safety performance of the entire liner system.

In applications such as landfill barriers, tailings ponds, and chemical containment, this increased reliability is essential for meeting environmental compliance and avoiding costly maintenance issues.

2. Faster, More Efficient Installation

Covering a large area naturally requires time, labor, and careful coordination. However, wider rolls allow teams to lay down nearly twice the coverage with each pass. The reduction in welding work not only speeds up installation but also shortens the project timeline as a whole.

Whether the project is located in a remote mining area or a busy construction zone, the ability to complete liner installation earlier can reduce machinery rental costs, limit weather-related delays, and create room for subsequent construction stages to start sooner.

3. Lower Overall Project Costs

Although wide-width geomembranes may appear more specialized, they often reduce total project costs when evaluated from a full life-cycle perspective. Fewer seams mean less welding equipment on-site, fewer technicians needed for seam testing, and lower labor hours.

In addition, simplified installation reduces the risk of installation errors—one of the most frequent causes of rework and unexpected costs. Over the lifespan of the project, improved performance and reduced maintenance demands also translate into long-term savings.

4. Improved Flatness and Smoother Coverage

Uniform coverage plays an important role in the long-term stability of a liner system. The large-format design of 10m wide HDPE geomembrane provides a smoother finish with fewer visible transitions between sheets.

This contributes to:

better stress distribution

higher tear resistance

improved stability on slopes

reduced risk of wrinkles, folds, or subgrade-related deformation

In reservoirs, fish ponds, and water conservation projects, smoother coverage also improves water retention and reduces sediment accumulation along the liner surface.

5. High Durability in Harsh Environments

The 10m wide HDPE geomembrane is produced from high-quality virgin HDPE resin, ensuring strong resistance to:

ultraviolet radiation

chemicals and acidic liquids

high temperatures

puncture and tearing

long-term aging

These characteristics make it suitable for use in exposed environments, from high-altitude mining regions to tropical climates with intense sunlight. The ability to maintain performance over decades is a key reason why HDPE geomembrane is recognized as a reliable engineering material worldwide.

6. Ideal for a Wide Range of Large-Scale Engineering Projects

Because it balances durability, coverage, flexibility, and cost-effectiveness, the 10m wide HDPE geomembrane is widely used in large-scale industrial and environmental projects such as:

Municipal landfills and hazardous waste containment

Mining tailings ponds and heap leaching pads

Large agricultural irrigation reservoirs

Industrial wastewater treatment facilities

Canal lining and water transport systems

Aquaculture farms and decorative lakes

Flood control and emergency water storage

Its versatility ensures that it performs reliably whether the project requires full containment, waterproofing, reinforcement, or environmental protection.

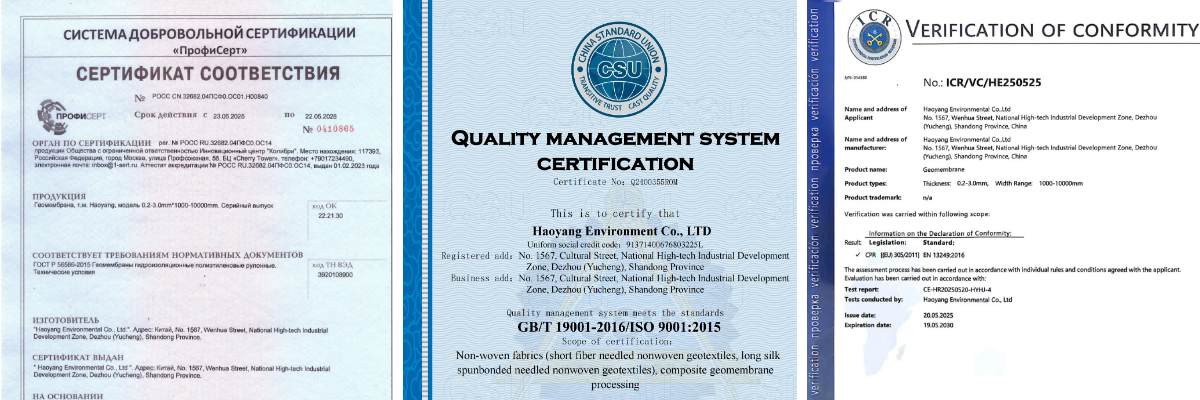

Production Quality Standards That Ensure Reliability

A critical factor that determines the performance of a wide-width geomembrane is the manufacturing process. Advanced production lines capable of producing 10m width sheets require precision temperature control, stable extrusion technology, and strict raw material selection.

Manufacturers typically use 100% virgin HDPE resin to achieve consistent thickness, high tensile strength, and long-term resistance to deformation. Strict international standards such as GM13, ISO 9001, and ISO 14001 are often followed during production and quality control.

Additionally, each roll undergoes thorough inspection for surface uniformity, tensile properties, elongation, and carbon black content to ensure long-term weathering resistance.

Why Contractors Prefer 10m HDPE Geomembranes for Mega Projects

From a practical standpoint, contractors value materials that help them deliver projects faster and more safely. The reduction in welding work alone is often enough justification for choosing wide-width geomembranes over standard options.

On job sites with tight schedules, difficult terrain, or limited technical manpower, the 10m geomembrane can significantly reduce on-site workload. Many contractors also note a reduction in post-installation testing time, as fewer seams mean fewer areas requiring destruction testing or vacuum testing.

For these reasons, the 10m HDPE geomembrane has become a preferred choice for international contractors working on large earthwork and environmental projects.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

The 10m wide HDPE geomembrane represents a major advancement in modern geosynthetic engineering. Its ability to reduce seams, increase installation efficiency, improve long-term durability, and lower total project costs makes it an ideal solution for large-scale applications. As engineering standards continue to rise and environmental regulations become increasingly strict, wide-width HDPE geomembranes offer project owners a reliable, practical, and cost-effective material for creating secure and sustainable containment systems.

Whether used in landfills, mining operations, agricultural water systems, or industrial containment facilities, the 10m wide HDPE geomembrane delivers the performance and efficiency required by today’s large-scale construction environments.