HDPE Geomembrane for Mining Projects: Chemical Resistance and Durability You Can Trust

1. Superior Chemical Resistance

Withstands acidic, alkaline, and high-salinity leachates commonly found in mining operations.

2. Exceptional Durability

High tensile strength and puncture resistance ensure long-term performance under harsh site conditions.

3. UV & Weather Resistant

Maintains stability and mechanical properties even under prolonged sunlight and extreme temperatures.

4. Reliable Containment Performance

Provides excellent impermeability to prevent leakage of tailings, process water, and hazardous slurry.

5. Cost-Effective Long Service Life

Low maintenance requirements reduce operational costs over the lifespan of the mining project.

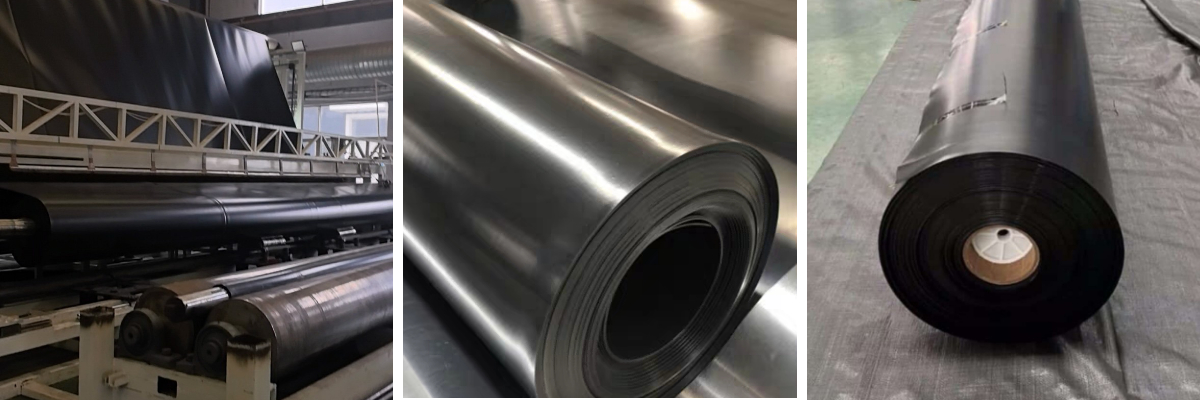

Mining projects operate in some of the harshest environments in the world. From aggressive chemical solutions in heap leaching systems to abrasive tailings, high loads, and fluctuating temperatures, every material used on-site must withstand extreme conditions while offering consistent and long-term performance. Among today’s engineering materials, HDPE geomembrane has become the preferred choice for mine operators and engineering contractors due to its outstanding chemical resistance, durability, environmental integrity, and cost-effectiveness.

As environmental regulations become stricter and mining companies pursue safer and more sustainable operations, choosing the right geomembrane liner is critical. A high-quality HDPE geomembrane not only prevents leakage and soil contamination but also protects valuable process solutions, supports stable infrastructure, and ensures long service life even in demanding mineral extraction environments.

Engineered for Harsh Chemical Environments

One of the defining challenges in modern mining is the presence of aggressive chemicals. Heap leaching, tailings storage, and process water circuits often contain acidic or alkaline solutions, solvents, and heavy-metal-rich fluids. These substances can degrade ordinary liner materials, leading to cracks, softening, or chemical reactions that compromise the containment system.

HDPE geomembrane is specifically engineered to resist these chemical threats. Its molecular structure provides high inertness, allowing the liner to maintain its properties when exposed to sulfuric acid, cyanide solutions, chloride compounds, and other chemical agents widely used in mineral processing. This superior chemical resistance ensures that the containment system remains stable over years of continuous operation.

For mining companies, this translates into safer operations, fewer environmental risks, and significantly lower repair or replacement costs.

Superior Mechanical Strength and Long-Term Durability

Mining operations often involve heavy equipment, sharp rocks, and dynamic loads. The geomembrane material must therefore provide exceptional mechanical performance. HDPE geomembrane offers high tensile strength, puncture resistance, tear resistance, and dimensional stability, allowing it to withstand:

Weight and pressure from ore heaps

Abrasion from tailings and sediments

Mechanical stress during installation

Movement in foundations and subgrade

Even when exposed to extreme temperatures—whether in high-altitude regions or hot desert climates—HDPE geomembrane retains its shape, flexibility, and structural reliability. The material's resistance to environmental stress cracking (ESCR) further enhances its ability to function dependably under long-term load.

A mining project typically spans multiple years or even decades. Using an HDPE geomembrane with proven durability ensures that the containment systems will continue performing without major degradation, offering peace of mind throughout the entire project lifecycle.

Optimized for Environmental Protection and Regulatory Compliance

Today’s mining operations must meet increasingly strict environmental protection standards. Any leakage from tailings ponds, process water reservoirs, or chemical storage areas can lead to contamination of surrounding soil, rivers, and groundwater resources. Remediation costs and legal liabilities can be enormous.

HDPE geomembrane plays a critical role in environmental risk control. Its low permeability prevents chemicals and mining effluents from migrating into the environment. When combined with geotextiles, drainage layers, or GCLs (Geosynthetic Clay Liners), the composite lining system offers robust, multi-layer protection suitable for high-risk containment zones.

Using a certified geomembrane liner also helps mining companies meet local and international standards such as ISO, GRI, and environmental mining guidelines. High-quality HDPE liners contribute directly to sustainable mining practices by reducing waste, conserving water through reuse systems, and preventing ecological damage.

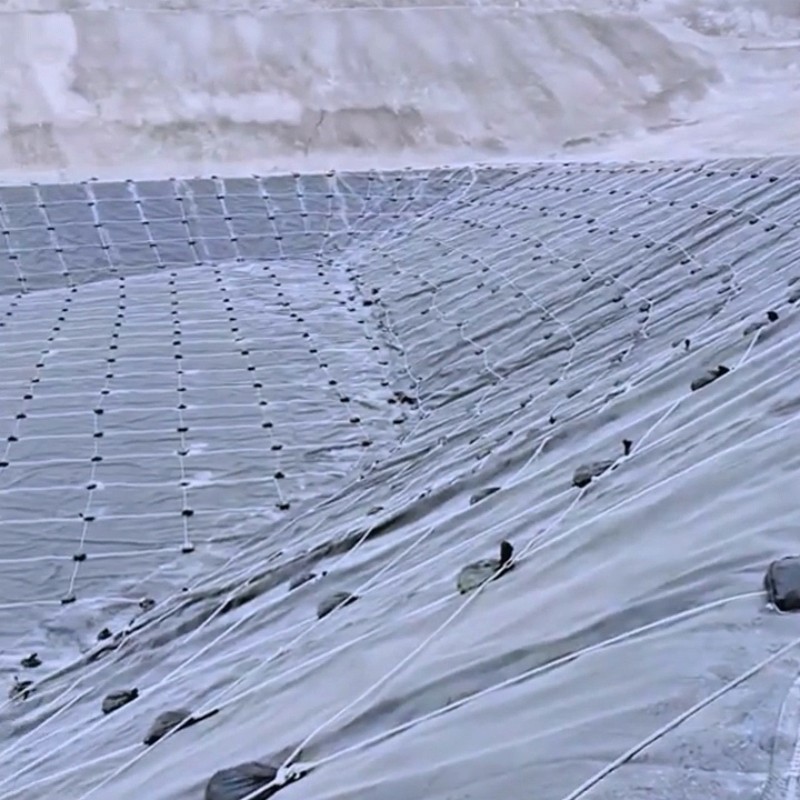

Reliable Performance in Heap Leaching Applications

Heap leaching is one of the most widespread mineral extraction methods, especially in gold, copper, and silver mining. The success of the leaching process depends heavily on the performance of the geomembrane system. Any failure in the basal or side-slope liners could lead to loss of valuable solutions or environmental contamination.

HDPE geomembranes are ideal for heap leach pads due to:

High chemical resistance against acidic leach agents

Smooth or textured surface options for slope stability

Excellent compatibility with geosynthetic drainage layers

Resistance to concentrated sunlight and thermal cycling

Their long-term performance ensures that process solutions remain contained and recoverable, supporting both safety and operational efficiency.

UV and Weathering Resistance for Long Outdoor Exposure

Mining sites often expose materials to intense sunlight, wind, rainfall, and temperature fluctuations. Unlike other plastic liners that degrade quickly under UV exposure, HDPE geomembrane is formulated with carbon black and stabilizers, giving it excellent resistance to:

UV radiation

Oxidative degradation

Thermal stress

Freeze–thaw cycles

This makes HDPE geomembrane particularly suitable for uncovered installations such as evaporation ponds, stormwater lagoons, and heap leach pads operating year-round in outdoor environments.

Efficient Welding, Installation, and Quality Assurance

In addition to material properties, installation quality is crucial for mining applications. HDPE geomembrane supports:

High-quality fusion welding

Excellent seam strength

Easy on-site testing with air-channel or vacuum methods

Professional installation teams can deploy large panels efficiently, reducing project timelines and minimizing risks of improper seam formation. Proper QA/QC procedures ensure that the entire containment system meets all performance requirements before each phase of mining operations begins.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

Cost-Effective Long-Term Investment

While some alternative materials may seem cheaper initially, HDPE geomembrane offers the best long-term value. Its durability, minimal maintenance requirements, and long lifespan mean significantly reduced operational costs. Mining companies benefit from fewer shutdowns, fewer repairs, and more stable containment systems that support uninterrupted production.

Over the entire project lifecycle, HDPE geomembrane stands out as one of the most economical and reliable solutions available.