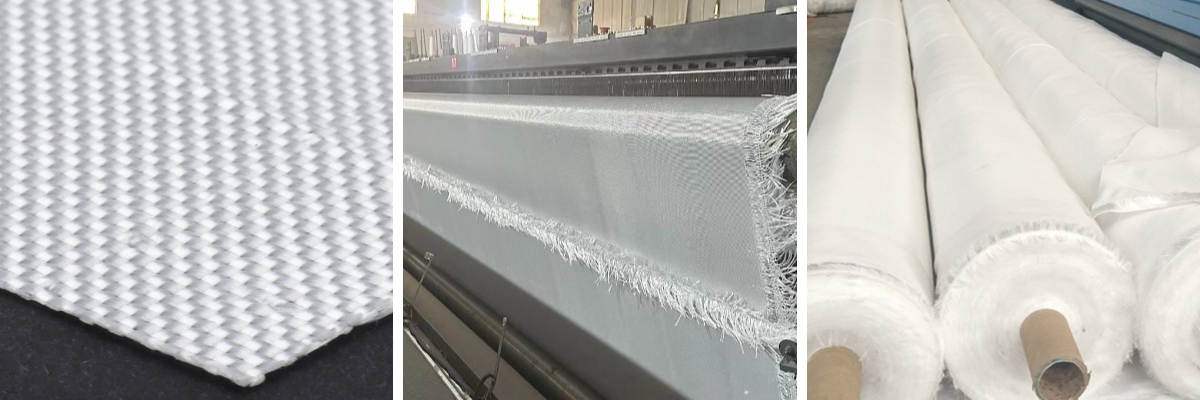

250g PET Woven Geotextile

1. Dynamic Soil Reinforcement: 250g/m² PET woven geotextile delivers ≥18 kN/m tensile strength (MD), tackling heavy loads in highways and railway subgrades with ease.

2. Chemically Invincible: Built to resist aggressive acids, alkalis, and industrial contaminants, ensuring longevity in landfills and chemical storage zones.

3. Smart Filtration System: Its precision-woven matrix allows 0.4–0.7 cm/s water flow while trapping fine soil particles, optimizing drainage in sports fields and irrigation networks.

4. Extreme Environment Ready: Withstands 1200+ hours of UV exposure without losing integrity, making it ideal for desert highways or coastal erosion control.

250g/m² PET Woven Geotextile: Redefining Geosynthetic Excellence

The 250g/m² PET Woven Geotextile is a revolutionary geosynthetic material that combines cutting - edge engineering with sustainable design principles. Crafted from high - quality polyethylene terephthalate (PET) filaments, this geotextile sets new standards in strength, durability, and functionality, making it the go - to choice for a diverse range of geotechnical, environmental, and construction applications.

1. Technical Specifications

Property | Specification | Testing Standard |

Weight | 250g/m² | ASTM D5261 |

Thickness | 0.8 - 1.0 mm | ASTM D5199 |

Tensile Strength (Machine Direction) | ≥18 kN/m | ISO 10319 |

Tensile Strength (Cross Direction) | ≥15 kN/m | ISO 10319 |

Elongation at Break (Machine Direction) | ≤22% | ISO 10319 |

Elongation at Break (Cross Direction) | ≤25% | ISO 10319 |

CBR Puncture Strength | ≥2.0 kN | ASTM D6241 |

Permeability | 0.4 - 0.7 cm/s | ASTM D4491 |

Chemical Resistance | Excellent against alkalis, good against acids | ASTM D543 |

UV Resistance | Retains ≥85% of tensile strength after 1200 hours of UV exposure | ASTM G154 |

2. Innovative Product Features

(1) Nano - Enhanced Weaving Technology

Unlike traditional geotextiles, our 250g/m² PET Woven Geotextile utilizes a proprietary nano - enhanced weaving process. This advanced technique creates a super - dense yet flexible fabric structure, optimizing the balance between open voids for water flow and a tight weave to prevent soil particle migration. As a result, it offers unparalleled filtration efficiency and separation performance in even the most challenging soil conditions.

(2) Molecular - level Material Engineering

The PET filaments used in this geotextile undergo a unique molecular - level treatment during production. This process aligns the polymer chains in a specific orientation, significantly enhancing the material's mechanical properties. The result is a geotextile with superior tensile strength, tear resistance, and abrasion resistance, ensuring it can withstand heavy loads and harsh environments.

3. Unmatched Core Advantages

(1) Heavy - duty Load - bearing Capacity

With a machine - direction tensile strength of ≥18 kN/m, the 250g/m² PET Woven Geotextile acts as a powerful "geotechnical backbone" in infrastructure projects. In large - scale road construction, it effectively distributes the weight of heavy traffic, reducing subgrade deformation and extending the lifespan of the pavement. Its high load - bearing capacity also makes it ideal for supporting the construction of industrial facilities and warehouses.

(2) Chemical - resistant Barrier

Engineered to resist a wide spectrum of chemicals, this geotextile remains intact in the presence of alkalis, acids, and industrial solvents. In chemical plants and waste treatment facilities, it serves as a reliable protective layer, preventing soil contamination and safeguarding the environment. Its chemical resistance also makes it suitable for use in areas with high levels of soil salinity.

(3) Self - regulating Filtration Mechanism

The geotextile's woven structure functions like a smart filter. It allows water to permeate at an optimal rate of 0.4 - 0.7 cm/s while retaining fine soil particles. This self - regulating property ensures efficient drainage in agricultural fields, sports stadiums, and drainage systems, preventing waterlogging and soil erosion without the need for frequent maintenance.

(4) Ultra - durable Performance

Thanks to its UV - stabilized PET composition and advanced manufacturing process, the geotextile maintains its performance even after prolonged exposure to sunlight, extreme temperatures, and mechanical stress. In outdoor projects such as coastal erosion control and desert road construction, it retains ≥85% of its tensile strength after 1200 hours of UV exposure, providing long - term reliability.

(5) Sustainable and Cost - effective

Made from 100% recyclable PET, this geotextile supports sustainable construction practices. Its recyclability not only reduces the environmental impact but also makes it eligible for green building certifications. Additionally, its lightweight design and ease of installation reduce labor costs and project timelines. With a long service life and low maintenance requirements, it offers excellent cost - effectiveness over the entire project lifecycle.

4. Diverse Application Scenarios

(1) Infrastructure Marvels

Highway and Railway Networks: Installed as a subgrade reinforcement layer, the geotextile improves the load - bearing capacity of the roadbed, reduces pavement rutting, and minimizes the need for frequent repairs. In railway construction, it stabilizes the ballast layer, ensuring smooth train operations and extending the track's lifespan.

Bridges and Tunnels: Used in the foundation and backfill areas of bridges and tunnels, the geotextile provides soil stabilization and filtration, preventing soil movement and water seepage that could compromise the structural integrity of these critical infrastructure components.

(2) Environmental Guardians

Landfill Containment: As a key component of landfill lining systems, the geotextile protects the underlying geomembrane from punctures and tears caused by sharp debris. It also helps in the proper drainage of leachate, preventing groundwater contamination and ensuring environmental safety.

Coastal Protection: In coastal erosion control projects, the geotextile is used to create permeable breakwaters and revetments. Its ability to filter water and retain soil particles helps in stabilizing the shoreline, protecting coastal communities and ecosystems from the erosive forces of the sea.

(3) Agricultural Innovations

Irrigation Efficiency: Placed around agricultural drainage pipes, the geotextile filters out soil particles, preventing pipe blockages and improving the efficiency of irrigation systems. It also helps in maintaining proper soil aeration, promoting healthy root growth and increasing crop yields.

Soil Improvement: In land reclamation and soil amendment projects, the geotextile is used to separate different soil layers, preventing soil mixing and facilitating the establishment of a suitable growing medium for crops. Its filtration properties also help in removing excess salts and contaminants from the soil.

For customized 250g/m² PET Woven Geotextile solutions tailored to your specific project needs, contact our expert team today. We offer comprehensive technical support, on - site consultation, and flexible product customization options to ensure the success of your project.