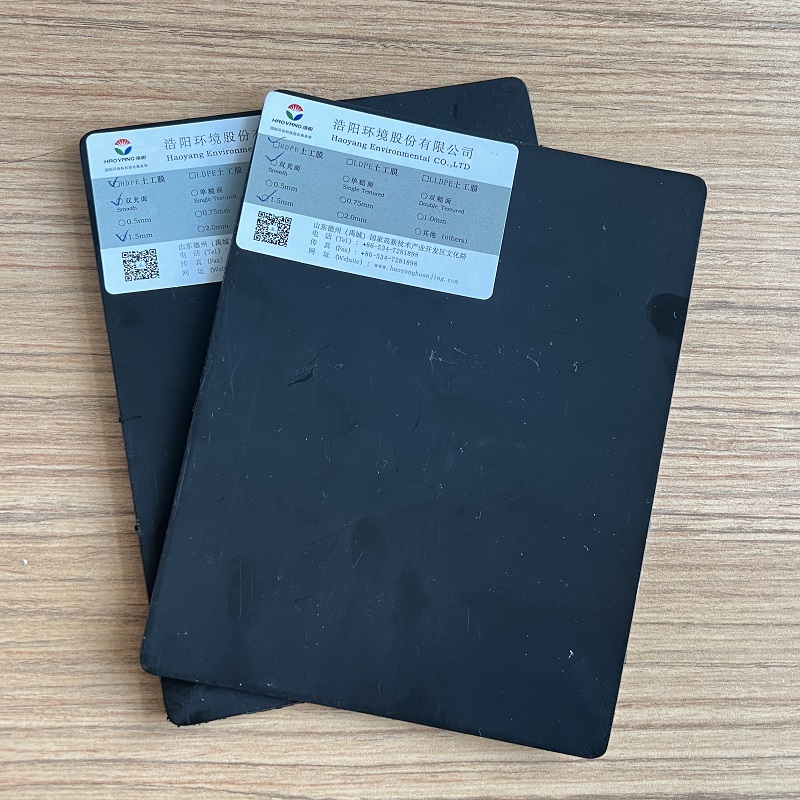

80mil HDPE Geomembrane Liner

Superior Puncture Resistance

Withstands loads up to 650 N, making it ideal for applications with sharp debris or heavy equipment traffic.

Enhanced Chemical Durability

Resists aggressive chemicals, including hydrocarbons and oxidizing agents, ensuring long-term containment integrity.

Extended Service Life

UV-stable formulation and high tensile strength provide a minimum lifespan of 50 years in most environments.

80mil HDPE Geomembrane Liner: Engineering Excellence for Heavy-Duty Containment

The 80mil HDPE geomembrane liner (2.03 mm thickness) represents the pinnacle of heavy-duty geosynthetic technology, designed to meet the most demanding containment challenges in civil engineering, environmental protection, and industrial infrastructure. With enhanced thickness and robust mechanical properties, this material excels in applications requiring superior puncture resistance, chemical durability, and long-term structural integrity. This article delves into the technical specifications, applications, and advantages of 80mil HDPE liners, supported by industry-standard data and performance benchmarks.

Key Properties of 80mil HDPE Geomembrane Liners

HDPE geomembranes are renowned for their resistance to environmental stressors, and the 80mil thickness amplifies these attributes for high-stress environments. Below is a detailed analysis of its physical, mechanical, and chemical characteristics:

Physical Properties

| Property | Value | Test Method |

Thickness | 80 mil (2.03 mm) | ASTM D5199 |

Density | 0.94–0.96 g/cm³ | ASTM D792 |

Melting Point | 125–135°C | ASTM D3418 |

Water Vapor Transmission | <0.01 g/m²/day | ASTM E96 |

UV Resistance | Excellent (>50 years) | ASTM G154 |

Mechanical Properties

| Property | Value | Test Method |

Tensile Strength (MD/TD) | 55 MPa / 50 MPa | ASTM D638 |

Elongation at Break | 750% (MD/TD) | ASTM D638 |

Puncture Resistance | 650 N | ASTM D4833 |

Tear Resistance | 200 N | ASTM D1004 |

Shear Strength | 45 kPa | ASTM D5321 |

Impact Resistance | 1.2 m (1 kg weight) | ASTM D4272 |

Chemical Resistance

| Chemical | Resistance Level |

Acids (pH 0–14) | Excellent |

Bases | Excellent |

Salts | Excellent |

Hydrocarbons | Excellent |

Alcohols | Good |

Oxidizing Agents | Fair |

Applications of 80mil HDPE Geomembrane Liners

The 80mil HDPE liner’s enhanced thickness and durability make it indispensable for large-scale, high-risk projects:

Municipal and Industrial Landfills

Primary liner for hazardous waste landfills, complying with stringent EPA and EU regulations.

Resists leachate with total dissolved solids (TDS) exceeding 50,000 ppm.

Mining Tailings Dams

Withstands abrasion from coarse tailings and chemical leaching agents (e.g., copper sulfate, cyanide).

Supports slopes up to 3H:1V without deformation.

Oil and Gas Infrastructure

Lines brine ponds, fracking fluid pits, and drilling waste containment areas.

Resists hydrocarbon permeation (<0.01 g/m²/day).

Water Reservoirs and Canals

Prevents seepage in irrigation canals and drinking water reservoirs.

Withstands hydrostatic pressures up to 100 meters.

Agricultural and Aquaculture Ponds

Retains water in saline environments (up to 50,000 ppm TDS).

Resists degradation from fertilizers and pesticides.

Secondary Containment

Protects soil and groundwater from spills in chemical storage facilities.

Meets SPCC (Spill Prevention, Control, and Countermeasure) requirements.

Installation and Maintenance Guidelines

Proper installation is critical to unlocking the full potential of 80mil HDPE liners:

Subgrade Preparation

Excavate to a minimum compacted density of 95% (Proctor test).

Remove rocks, roots, and debris larger than 50 mm.

Seaming and Welding

Use extrusion welding for seams wider than 150 mm.

Conduct destructive testing (ASTM D6392) on 1% of all seams.

Protection Systems

Install a 600 g/m² nonwoven geotextile above and below the liner.

Use concrete anchors spaced every 2 meters for wind uplift resistance.

Inspection Protocols

Perform air channel tests (ASTM D4437) on all seams.

Conduct electrical leak location surveys (ASTM D7007) biannually.

Repair Procedures

Patch holes larger than 6 mm with HDPE patches (200 mm x 200 mm).

Use hot air welders for repairs in temperatures below 10°C.

Environmental and Economic Impact

The 80mil HDPE geomembrane offers a compelling return on investment through its lifespan and performance:

Cost Efficiency: Reduces containment costs by up to 50% over 50 years compared to clay liners.

Sustainability: HDPE is 100% recyclable, with reclaim rates exceeding 90% in many regions.

Carbon Footprint: Lightweight design reduces transportation emissions by 30% compared to concrete.

Conclusion

The 80mil HDPE geomembrane liner sets the benchmark for heavy-duty containment solutions, offering unmatched durability, chemical resistance, and installation flexibility. Its proven performance in landfills, mining operations, and industrial facilities underscores its role as a critical tool for sustainable infrastructure development. By combining technical precision with environmental responsibility, this material continues to redefine the standards of geosynthetic engineering.