0.5mm HDPE Dam Liner

1.Excellent Impermeability – Effectively prevents water seepage, ensuring reliable water storage.

2.Lightweight & Flexible – Easy to transport, handle, and install, even on irregular surfaces.

3.UV & Chemical Resistance – Durable in harsh outdoor environments and resistant to acids, salts, and chemicals.

4.Cost-effective – Lower material and installation costs, ideal for projects with tight budgets.

5.Easy Welding & Seaming – Supports fast, strong, and leak-proof seams for secure containment.

0.5mm HDPE Dam Liner

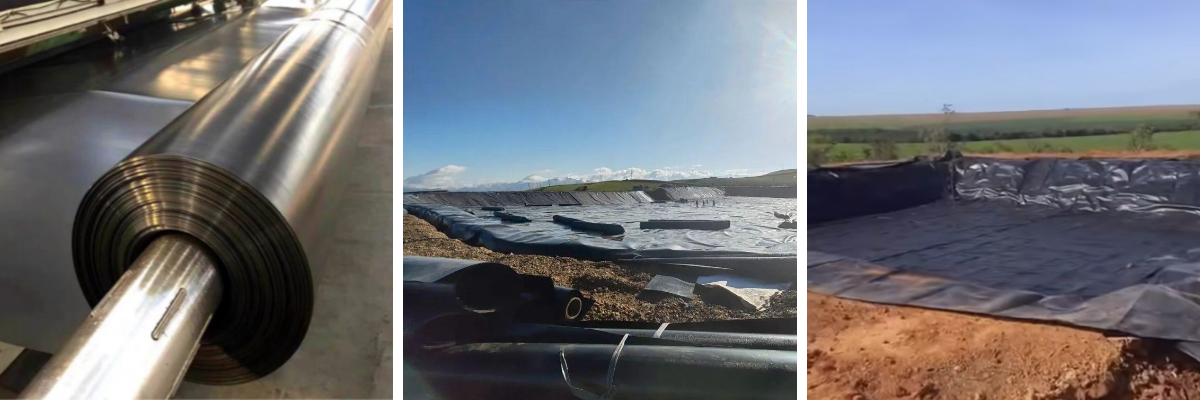

In the modern world, where water resource management is becoming increasingly critical, the choice of lining material for dams, ponds, and reservoirs plays a pivotal role in determining the longevity, efficiency, and environmental impact of water storage structures. Among various geomembrane solutions available today, the 0.5mm HDPE dam liner stands out as a popular choice for projects requiring flexibility, lightweight handling, and reliable impermeability at an economical cost.

Understanding HDPE and Its Role in Dam Lining

High-Density Polyethylene (HDPE) is a thermoplastic polymer known for its outstanding chemical resistance, durability, and excellent water impermeability. Due to its unique molecular structure, HDPE has a high strength-to-density ratio, making it a preferred choice for geomembrane production. In dam lining, HDPE serves as a protective barrier that prevents water seepage into the soil, controls erosion, and safeguards the surrounding ecosystem.

A 0.5mm thickness HDPE dam liner, in particular, is designed for applications where moderate mechanical stress is expected, and where cost and ease of installation are major considerations. While thicker liners (such as 1mm or 1.5mm) are used in high-pressure or rocky environments, the 0.5mm option is ideal for small to medium-scale irrigation dams, fish ponds, agricultural water storage, and temporary containment structures.

Key Benefits of 0.5mm HDPE Dam Liner

1.Lightweight and Flexible

With a thickness of just 0.5mm, this liner is highly flexible and easy to maneuver, even in irregularly shaped reservoirs. The lightweight nature reduces the logistical burden during transportation and installation, enabling faster project completion.

2.Cost-effective Solution

The lower material cost of a 0.5mm liner makes it attractive for projects with tight budgets. It allows landowners, farmers, and small-scale project managers to install effective water containment without significant capital investment.

3.Excellent Impermeability

Despite its thinner profile, HDPE’s intrinsic properties provide a reliable barrier against water seepage. This impermeability helps maintain water levels, prevents soil erosion, and reduces water loss.

4.Chemical and UV Resistance

HDPE geomembranes are known for their resistance to a wide range of chemicals, acids, and salts commonly found in water and soil. Additionally, HDPE exhibits excellent UV resistance, making the liner suitable for outdoor applications exposed to sunlight over extended periods.

5.Ease of Installation and Welding

The liner can be joined on-site using thermal fusion welding or extrusion welding. These methods create strong, leak-proof seams, even in challenging terrain. The thin profile of 0.5mm HDPE makes seaming quicker and less energy-intensive compared to thicker liners.

Common Applications

1. Agricultural Ponds and Irrigation Dams:

Farmers widely use 0.5mm HDPE liners to line irrigation ponds and small dams. The liner effectively prevents seepage into the subsoil, helping maintain consistent water availability for crops.

2. Aquaculture and Fish Ponds:

In aquaculture, maintaining water quality and minimizing seepage are critical. A 0.5mm HDPE liner provides a smooth, impermeable base that supports easy cleaning, reduces disease risk, and keeps water levels stable.

3. Decorative and Landscaping Ponds:

Landscapers use these liners to construct garden ponds and water features due to their flexibility and ease of shaping around rocks and curves.

4. Temporary Water Containment:

Construction sites and mining operations sometimes require temporary water storage solutions. A lightweight liner can be deployed quickly and removed easily when the project ends.

Design and Installation Considerations

While the 0.5mm HDPE dam liner offers many advantages, proper installation is crucial to ensure long-term performance.

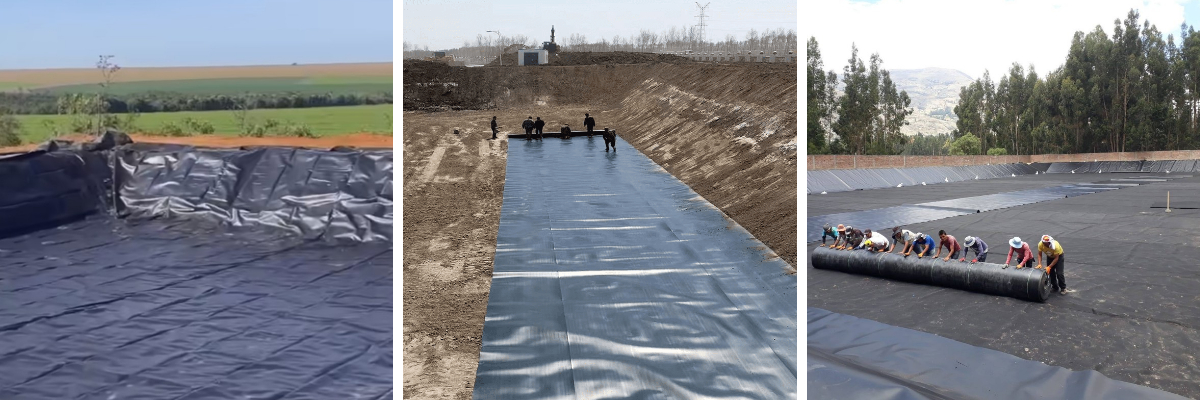

Site Preparation:

The ground should be cleared of sharp objects, stones, and roots that might puncture the liner. In many cases, an additional layer of geotextile under the HDPE liner provides extra protection.

Seaming and Anchoring:

Welded seams must be tested (e.g., through air pressure or vacuum testing) to confirm impermeability. The liner should be anchored properly along the dam crest or in anchor trenches to prevent movement due to wind or water pressure.

Protection Layer:

For projects exposed to heavy machinery or livestock, adding a protective layer (such as soil, sand, or geotextile) over the liner helps reduce the risk of mechanical damage.

Environmental Impact and Sustainability

One of the major concerns in large-scale dam construction is environmental sustainability. HDPE liners help reduce environmental impact by:

1.Minimizing water seepage, conserving water resources.

2.Preventing contamination of groundwater by isolating stored water from surrounding soil.

3.Having a long service life (often over 15–20 years under proper conditions), which reduces replacement frequency and associated environmental disturbance.

Moreover, HDPE is recyclable. At the end of its service life, it can be processed into other plastic products, contributing to a circular economy.

Limitations and Best Practices

Although the 0.5mm HDPE dam liner is suitable for many applications, it may not be ideal for:

1.Rocky sites or areas with high mechanical stress.

2.Large reservoirs where water pressure is significantly higher.

In such scenarios, thicker liners (0.75mm, 1mm, or more) should be considered to ensure safety and durability.

Best practices include:

1.Consulting experienced geomembrane installers.

2.Performing regular inspections to check for damage.

3.Ensuring proper drainage design to avoid liner uplift due to gas or water pressure.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

The 0.5mm HDPE dam liner is a versatile, cost-effective, and reliable solution for small to medium-scale water containment applications. Its lightweight and flexible nature make it especially suitable for projects with complex shapes, budget constraints, or where rapid installation is required.

By providing excellent impermeability and chemical resistance, this liner helps maintain water resources, supports sustainable agriculture, and contributes to environmental conservation. With proper installation and maintenance, a 0.5mm HDPE liner can deliver long-lasting performance, protecting both the water it contains and the environment it supports.

For anyone considering lining a dam, pond, or reservoir, exploring the benefits of a 0.5mm HDPE dam liner is a practical step toward effective and sustainable water management.