HDPE Dam Liner for Reservoir Waterproofing

1.Excellent Waterproofing – Provides superior anti-seepage performance to ensure reliable water retention.

2.High Durability – Manufactured from 100% virgin HDPE for long service life.

3.UV & Chemical Resistance – Withstands sunlight, acids, alkalis, and harsh environments.

4.Strong Tensile Strength – Resists tearing, puncture, and mechanical stress.

5.Easy Installation – Flexible and weldable for quick, secure field applications.

6.Cost-Effective Solution – Low maintenance with long-term performance, reducing project costs.

Reservoirs play a crucial role in water storage, irrigation, aquaculture, and environmental management. Ensuring their waterproofing is essential to maintain water levels, prevent seepage, and secure long-term operation. Among the available solutions, HDPE dam liner has emerged as one of the most reliable and cost-effective materials for reservoir waterproofing. Manufactured from high-density polyethylene (HDPE), this geomembrane provides exceptional protection, durability, and performance under challenging environmental conditions.

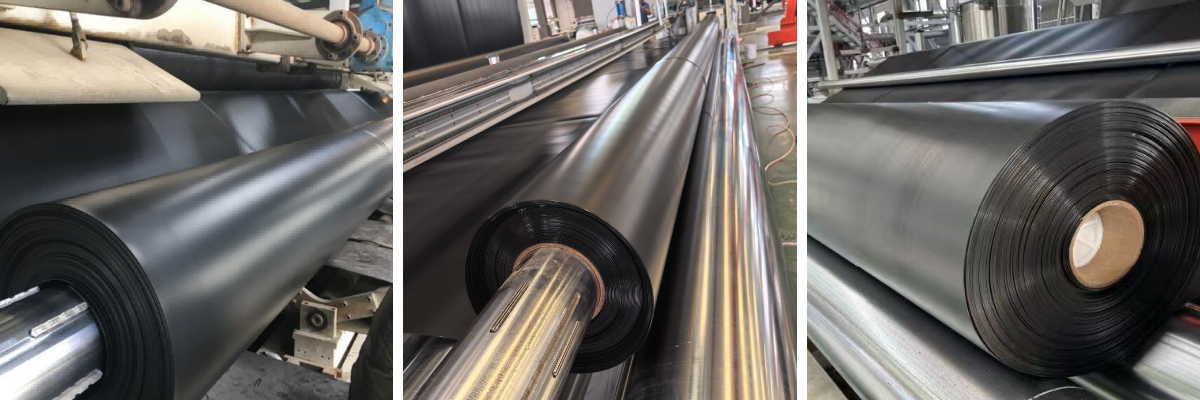

What is an HDPE Dam Liner?

An HDPE dam liner is a synthetic geomembrane designed to provide impermeability for water reservoirs, ponds, canals, and landfills. It is produced using advanced extrusion and co-extrusion technology, ensuring consistent thickness, high tensile strength, and excellent resistance to environmental stress. Unlike traditional clay or concrete sealing methods, HDPE geomembrane liners offer superior performance with easier installation and lower maintenance requirements.

Key Advantages of HDPE Dam Liner for Reservoir Waterproofing

Excellent Waterproofing

HDPE geomembranes provide outstanding impermeability, preventing water seepage and loss. Their dense molecular structure ensures reliable water retention, which is particularly important in reservoirs designed for irrigation, aquaculture, or municipal supply.High Durability

Made from 100% virgin HDPE raw materials, these liners are engineered for long service life. They are resistant to puncture, cracking, and stress damage, making them suitable for both small and large-scale reservoir projects. With proper installation, HDPE liners can last for decades without significant degradation.UV and Chemical Resistance

Reservoirs are often exposed to direct sunlight and potential chemical contaminants. HDPE dam liners are specifically formulated with UV stabilizers, ensuring long-term resistance to solar radiation. They are also resistant to acids, alkalis, and organic matter, which allows them to perform reliably even in aggressive environments.Strong Tensile Strength

HDPE liners possess excellent tensile and tear resistance, making them capable of withstanding earth movements, settlement, and hydraulic pressure. This mechanical strength helps maintain the structural integrity of the reservoir even under demanding conditions.Easy Installation

Flexibility and weldability make HDPE dam liners easy to install. They can be seamed using hot wedge welding or extrusion welding, forming a secure, continuous waterproof barrier. This reduces the risk of leakage at joints and speeds up the construction process, ultimately lowering project timelines and labor costs.Cost-Effective Solution

Compared with traditional waterproofing materials, HDPE geomembranes require less maintenance and provide longer service life. This results in reduced operational costs and better return on investment for reservoir projects. Their lightweight structure also reduces transportation and handling expenses.

Applications of HDPE Dam Liners in Reservoirs

HDPE dam liners are widely used in:

Irrigation reservoirs to ensure reliable water storage for agriculture.

Aquaculture ponds to create clean, controlled water environments for fish and shrimp farming.

Municipal water supply reservoirs to secure long-term, contamination-free water storage.

Industrial reservoirs for chemical storage or process water containment.

Rainwater harvesting systems to maximize water conservation.

Why Choose HDPE Dam Liners for Reservoirs?

When compared with other materials like clay or concrete, HDPE geomembranes stand out due to their balance of cost, performance, and longevity. Clay liners are prone to cracking during dry seasons, and concrete structures often require expensive maintenance. In contrast, HDPE liners maintain consistent impermeability, are easier to repair if damaged, and provide long-term reliability.

Installation and Quality Assurance

To achieve the best waterproofing performance, HDPE dam liners should be installed by experienced professionals. Welding quality must be tested using non-destructive methods such as vacuum box testing or air pressure testing to ensure seam integrity. Reputable manufacturers also provide liners certified by international standards such as ISO, SGS, CE, and GOST, ensuring guaranteed quality and safety.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

For reservoir waterproofing, HDPE dam liners offer a superior solution by combining excellent impermeability, durability, and cost-effectiveness. Their proven resistance to UV exposure, chemicals, and mechanical stress ensures long-term water conservation and minimal maintenance. Whether used in agricultural irrigation, aquaculture, or municipal water supply systems, HDPE geomembrane liners provide reliable protection that safeguards resources and reduces overall project costs.

By choosing HDPE dam liners, project owners and contractors gain peace of mind knowing that their reservoirs are built to last and perform under the most demanding environmental conditions.

Your Trusted Source for HDPE Geomembrane Solutions

We manufacture and supply premium-quality HDPE dam liners using 100% virgin raw materials. With international certifications and successful applications in government and private projects worldwide, our products guarantee long-term performance and safety. Contact us today to discuss your reservoir waterproofing needs.