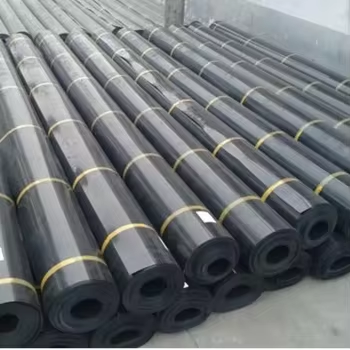

1.5mm PVC Geomembrane

Exceptional Chemical Resistance

Resists degradation from acids, alkalis, oils, and hydrocarbons, making it ideal for industrial wastewater and mining applications.Superior Flexibility

Conforms to irregular substrates and accommodates settlement/movement without cracking, critical for landfills and embankments.UV Stabilization

Carbon black additives and UV inhibitors ensure long-term outdoor durability (up to 30+ years in sunlight).

Geomembranes are synthetic lining materials used for containment and environmental protection applications. Among the various types available, 1.5mm PVC (Polyvinyl Chloride) geomembranes have gained popularity due to their balance of flexibility, durability, and cost-effectiveness. This article explores the technical specifications, applications, advantages, and environmental considerations of 1.5mm PVC geomembranes, supported by industry data and real-world use cases.

Technical Specifications of 1.5mm PVC Geomembrane

The performance of a geomembrane depends on its physical, mechanical, and chemical properties. Below is a detailed technical table outlining the key specifications of 1.5mm PVC geomembranes, based on standardized testing protocols:

| Property | Specification | Testing Standard |

Thickness | 1.5mm ± 0.05mm | ASTM D5199 |

Density | 1.40–1.50 g/cm³ | ASTM D792 |

Tensile Strength (MD/CD) | 20–30 MPa (MD), 18–25 MPa (CD) | ASTM D6693 |

Elongation at Break (MD/CD) | 300–400% (MD/CD) | ASTM D6693 |

Puncture Resistance | 200–300 N | ASTM D4833 |

Carbon Black Content | 2–3% | ASTM D1603 |

UV Resistance | 1,600 hours (ASTM G154) | ASTM D4437 |

Operating Temperature Range | -30°C to +70°C | Internal Lab Testing |

Chemical Resistance | Resistant to acids, alkalis, oils | ASTM D5322 |

Water Vapor Permeability | <0.1 g/cm²/day | ASTM E96 |

Key Properties Explained

Thickness Consistency: The 1.5mm thickness ensures optimal flexibility while maintaining puncture resistance.

Tensile Strength: High values in both machine (MD) and cross-machine (CD) directions indicate resistance to tearing under stress.

Elongation: The ability to stretch up to 400% makes it ideal for uneven terrain or settling substrates.

UV Resistance: Carbon black additives and UV stabilizers prevent degradation from sunlight exposure.

Chemical Resistance: PVC’s inert nature makes it suitable for harsh environments, including acidic or alkaline conditions.

Applications of 1.5mm PVC Geomembrane

1. Landfill Liners and Covers

Use Case: 1.5mm PVC geomembranes are widely used as primary or secondary liners in municipal solid waste (MSW) landfills.

Advantages:

Prevents leachate contamination of groundwater.

Flexibility accommodates landfill settlement.

Cost-effective compared to thicker alternatives (e.g., 2.0mm HDPE).

2. Mining Heap Leach Pads

Use Case: In gold and copper mining, PVC geomembranes line leach pads to contain cyanide or acidic solutions.

Advantages:

Resistant to chemical degradation from mining solutions.

Smooth surface reduces friction losses in irrigation systems.

3. Aquaculture Ponds

Use Case: Liners for fish and shrimp farming ponds.

Advantages:

Non-toxic to aquatic life.

Withstands prolonged water immersion.

Flexible installation in irregular pond shapes.

4. Agricultural Reservoirs

Use Case: Water storage for irrigation in arid regions.

Advantages:

Prevents seepage losses.

Resistant to fertilizers and pesticides.

5. Wastewater Treatment Lagoons

Use Case: Secondary containment for industrial or municipal wastewater.

Advantages:

Withstands biological and chemical degradation.

Easy to repair if damaged.

Advantages Over Other Geomembranes

1. Flexibility vs. HDPE

While HDPE geomembranes (e.g., 1.0mm or 2.0mm) are stiffer, 1.5mm PVC offers superior elongation, making it ideal for:

Wrinkled or uneven substrates.

Applications requiring fold-over seams.

2. Chemical Resistance vs. EPDM

EPDM rubber geomembranes excel in UV resistance but lack PVC’s broad chemical resistance, limiting their use in acidic or alkaline environments.

3. Cost Efficiency

1.5mm PVC typically costs 10–15% less than equivalent HDPE or EPDM options, with comparable lifespans when properly installed.

Installation Best Practices

1. Surface Preparation

Subgrades must be smooth, with no sharp objects. A 100mm layer of sand or geotextile is recommended as a protective cushion.

2. Welding Methods

Hot Wedge Welding: Ideal for field seams, with temperatures between 350–400°C.

Extrusion Welding: Used for repairs or complex geometries.

3. Seam Testing

Air Channel Test: Pressurized air detects leaks in welded seams.

Destructive Testing: Tensile tests on welded samples ensure compliance with ASTM D6392.

4. Anchoring

Secure edges with concrete anchors or trench backfilling to prevent wind uplift.

Environmental Considerations

1. Lifecycle Analysis

Service Life: 1.5mm PVC geomembranes typically last 20–30 years in landfill applications, depending on exposure.

Recyclability: Post-industrial scrap can be recycled into new products, though post-consumer recycling is less common.

2. Additive Concerns

PVC contains plasticizers (e.g., phthalates) to enhance flexibility. Modern formulations use non-toxic alternatives (e.g., citrate-based plasticizers) to mitigate environmental risks.

3. Carbon Footprint

Production energy is lower than HDPE, but end-of-life disposal remains a challenge. Incineration with energy recovery is a viable option in compliance with local regulations.

Case Study: Landfill Liner in Southeast Asia

A 50-hectare landfill in Southeast Asia used 1.5mm PVC geomembranes for its primary liner. Key outcomes:

Cost Savings: 12% lower material cost compared to HDPE alternatives.

Installation Speed: Flexibility reduced welding time by 20%.

Performance: After 8 years, no leachate leakage detected, with minimal UV degradation.

Conclusion

The 1.5mm PVC geomembrane is a versatile solution for containment applications, offering a balance of mechanical strength, chemical resistance, and cost efficiency. Its adaptability to complex geometries and harsh environments makes it a preferred choice in landfills, mining, and aquaculture. While environmental considerations around PVC persist, advancements in additive formulation and recycling technologies continue to improve its sustainability profile.