0.3mm Aquaculture Pond Liner

1.The 0.3mm HDPE liner’s UV-resistant coating ensures a 15–20 year lifespan, even in tropical climates.

2.With a puncture resistance of up to 400 N, it withstands accidental damage from tools and wildlife.

3.Its non-toxic composition guarantees safety for fish, shrimp, and surrounding ecosystems.

0.3mm Aquaculture Pond Liner: A Durable Solution for Modern Aquaculture Systems

Introduction

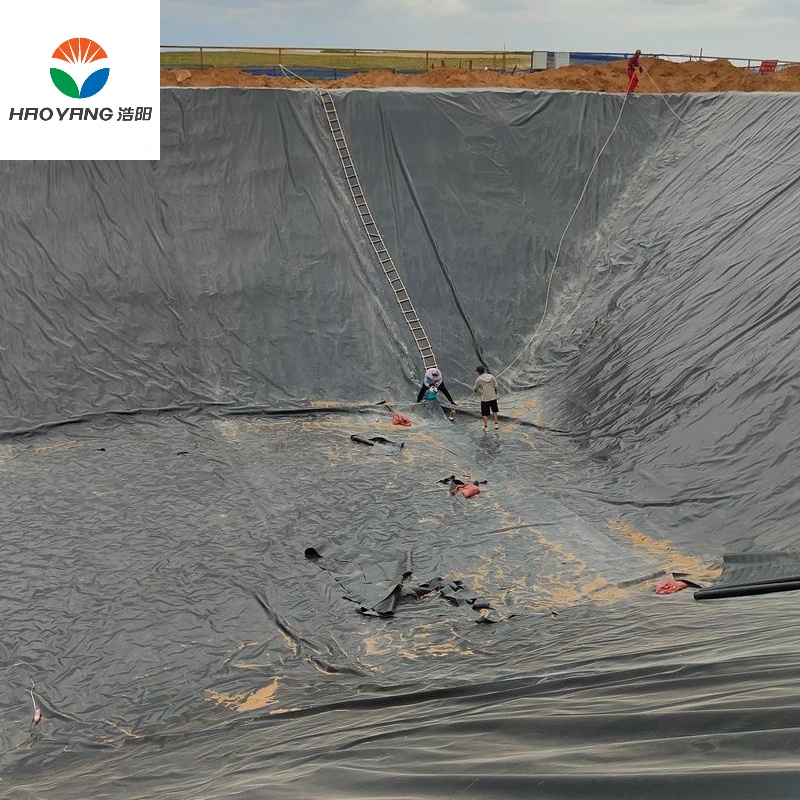

Aquaculture pond liners are critical components in modern fish and shrimp farming, serving as impermeable barriers that prevent water leakage, soil contamination, and chemical infiltration. Among the available options, 0.3mm-thick High-Density Polyethylene (HDPE) pond liners have emerged as a cost-effective and reliable choice for small- to medium-scale aquaculture operations. This article explores the technical specifications, performance advantages, and real-world applications of 0.3mm HDPE liners, supported by empirical data and industry insights.

Key Specifications and Material Properties

HDPE pond liners are engineered to withstand harsh environmental conditions while maintaining structural integrity over extended periods. The 0.3mm thickness strikes a balance between flexibility and durability, making it suitable for both temporary and permanent installations. Below are the core material properties and performance metrics:

Table 1: Technical Specifications of 0.3mm HDPE Aquaculture Pond Liners

| Parameter | Value | Testing Standard |

Thickness | 0.3mm (±0.05mm) | ASTM D5199 |

Tensile Strength (Yield) | 11–18 N/mm² | ASTM D6693 (Type IV) |

Tensile Elongation (Break) | 700% | ASTM D6693 |

Tear Resistance | 93–156 N | ASTM D1004 |

Puncture Resistance | 240–400 N | ASTM D4833 |

UV Resistance | 5,000+ hours (equivalent to 5+ years in tropical climates) | ASTM G154 |

Temperature Range | -70°C to 110°C | ASTM D638 |

Service Life | 15–20 years (under proper maintenance) | Industry consensus |

Table 2: Comparative Analysis of 0.3mm HDPE vs. Alternative Materials

| Material | 0.3mm HDPE | EPDM Rubber | PVC |

Cost per m² | 0.30–2.00 | 3.50–6.00 | 1.50–3.00 |

UV Stability | Excellent (UV-resistant coating) | Moderate (requires additives) | Poor (degrades rapidly) |

Flexibility | High (adapts to uneven terrain) | Very high | Low (prone to cracking) |

Chemical Resistance | Resistant to acids, salts, and fuels | Excellent (but vulnerable to oils) | Limited (degrades with ammonia) |

Installation Ease | Lightweight, easy to handle | Heavy, requires skilled labor | Rigid, requires precise joining |

Three Key Advantages of 0.3mm HDPE Pond Liners

Cost-Effectiveness Without Compromising Durability

The 0.3mm HDPE liner offers a lower material cost compared to thicker alternatives (e.g., 0.5mm or 1mm) while still providing sufficient strength for most aquaculture applications. Its lightweight nature reduces shipping and labor costs during installation.

Superior Resistance to Environmental Stressors

HDPE’s high tear resistance (93–156 N) and puncture resistance (240–400 N) ensure protection against root penetration, sharp objects, and animal activity. Additionally, its UV-resistant coating extends lifespan in sunny climates, a critical factor for outdoor ponds.

Eco-Friendly and Non-Toxic

HDPE liners are free from plasticizers and heavy metals, making them safe for aquatic life. They also prevent soil erosion and chemical leaching, reducing water pollution risks.

Applications in Aquaculture

The 0.3mm HDPE liner is widely used in:

Freshwater and Marine Fish Farms: For ponds housing tilapia, catfish, or sea bass.

Shrimp Farming: In Vannamei shrimp ponds, where seepage control is vital for maintaining salinity levels.

Ornamental Fish Ponds: In gardens or commercial aquariums, where aesthetics and water clarity matter.

Temporary Hatcheries: For seasonal breeding programs due to its ease of deployment and removal.

Case Study: Indonesia Shrimp Farming Project

A 2023 study in Indonesia compared 0.3mm HDPE liners to traditional clay-lined ponds. The HDPE ponds reduced water loss by 90%, cut cleaning time by 50%, and improved shrimp survival rates by 15% due to better oxygen retention and reduced turbidity.

Maintenance and Longevity

To maximize the lifespan of 0.3mm HDPE liners:

Avoid dragging heavy equipment over the surface.

Repair minor punctures immediately using HDPE patches and adhesives.

Store unused liners in a cool, dry place away from direct sunlight.

Conclusion

The 0.3mm HDPE aquaculture pond liner represents a versatile, affordable, and eco-conscious solution for modern farming systems. Its technical robustness, combined with ease of installation and low maintenance, makes it an ideal choice for operators seeking to optimize productivity while minimizing environmental impact.