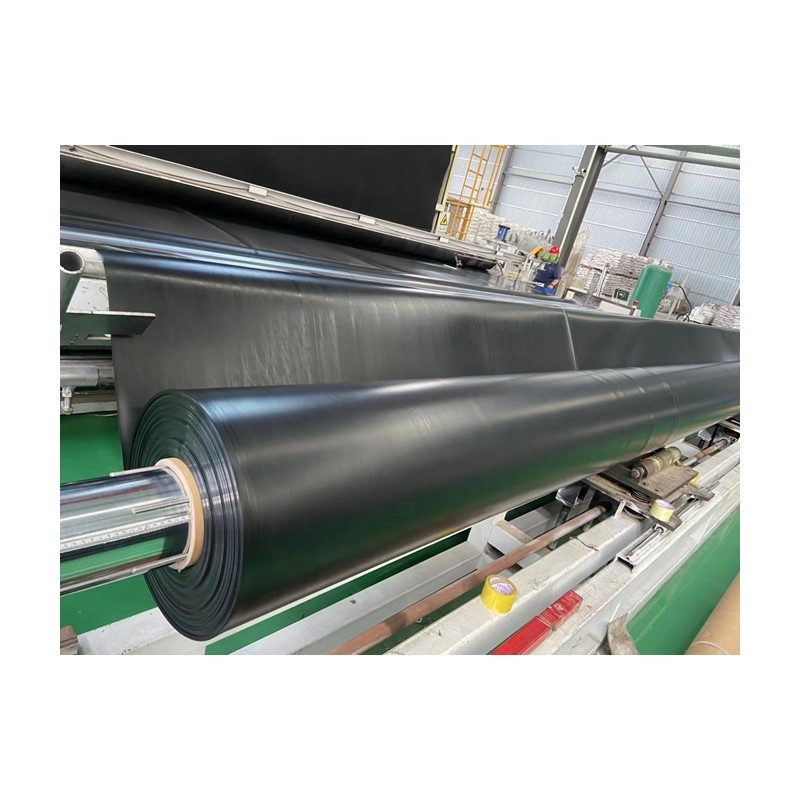

Virgin 100% 1mm HDPE Geomembrane Liner

1.100% Virgin Material Purity

Unlike recycled HDPE, virgin resin ensures consistent quality, eliminating odors and impurities that could compromise performance. This purity enhances stress crack resistance (>400 hours) and elongation at break (≥700%), critical for dynamic environments.

2.Environmental Stress Crack Resistance (ESCR)

The liner’s ESCR exceeds 500 hours under ASTM D1693 conditions, making it resilient to prolonged exposure to detergents, fuels, and agricultural chemicals. This property extends its service life in harsh conditions.

3.Global Compliance and Certification

Certified by ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ASTM GM13, the liner meets stringent safety and environmental standards. Its SGS-verified carbon black dispersion (Grade 1–2) ensures uniform UV protection.

Virgin 100% 1mm HDPE Geomembrane Liner: Engineering Excellence in Environmental Protection

Introduction

The global demand for high-performance geomembrane liners has surged across industries such as aquaculture, waste management, and water conservation. Among these, the Virgin 100% 1mm HDPE Geomembrane Liner stands out as a benchmark for durability, chemical resistance, and long-term reliability. Engineered from 100% virgin high-density polyethylene (HDPE) resin, this 1mm-thick liner combines cost-efficiency with robust physical properties, making it ideal for applications requiring impermeability and environmental adaptability. This article explores its technical specifications, applications, and competitive advantages.

Technical Specifications

Physical and Mechanical Properties

The 1mm HDPE geomembrane is manufactured under strict quality controls to meet international standards such as ASTM, ISO, and CE. Its composition includes 97.5% HDPE resin and 2.5% carbon black masterbatch, which enhances UV resistance and anti-aging properties. Key performance metrics are outlined below:

Table 1: Physical Properties of 1mm HDPE Geomembrane

| Property | Specification | Testing Standard (ASTM) |

Thickness | 1.00 ± 0.05 mm | D5199 |

Density | ≥0.94 g/cm³ | D1505 |

Tensile Yield Strength | ≥15 N/mm | D638 |

Tensile Breaking Strength | ≥27 N/mm | D638 |

Elongation at Break | ≥700% | D638 |

Tear Resistance (N) | 125 (Puncture: 352 N) | D1004/D4833 |

Stress Crack Resistance | ≥400 hours (Bell Test) | D1693 |

Carbon Black Content | 2.0–3.0% | D1603 |

Water Vapor Permeability | ≤1.0 × 10⁻¹³ g·cm/cm²·s·Pa | F1249 |

Surface and Dimensional Options

The liner is available in smooth or textured surfaces, with textured variants enhancing friction for slopes or steep terrains. Standard widths range from 1m to 10m, while lengths can be customized up to 500m per roll to minimize seams and installation time. Color options include black (UV-resistant), blue, and green, with black being the most popular for outdoor applications.

Applications Across Industries

1. Aquaculture and Fish Farms

In aquaculture, the 1mm HDPE geomembrane serves as a leak-proof barrier for ponds and tanks. Its impermeability prevents water seepage, reducing pumping costs by up to 30% while maintaining stable pH levels. A case study in the Philippines demonstrated a 25% increase in fish yield after replacing traditional clay liners with HDPE, attributed to improved water quality and disease control.

2. Landfills and Waste Containment

For hazardous waste landfills, the liner’s chemical resistance to acids, alkalis, and organic solvents ensures long-term containment. Its theoretical 25-year lifespan (when exposed to sunlight) and puncture resistance of 352 N make it suitable for protecting groundwater from leachate contamination.

3. Water Conservation and Mining

In reservoirs and canals, the geomembrane reduces water loss through evaporation and seepage. Mining operations use it for tailings ponds, where its -70°C to 110°C service temperature range accommodates extreme climates. A project in South Africa reported a 40% reduction in maintenance costs after adopting the 1mm HDPE liner.

Performance Advantages

Table 2: Comparative Advantages of 1mm HDPE Geomembrane

| Advantage | Description |

Cost-Effectiveness | Lower material and installation costs vs. concrete or clay liners. |

Durability | Resists UV degradation, chemicals, and mechanical stress for decades. |

Installation Efficiency | Lightweight and flexible, enabling rapid deployment even in remote areas. |

Conclusion

The Virgin 100% 1mm HDPE Geomembrane Liner represents a fusion of engineering precision and environmental responsibility. Its technical robustness, coupled with cost and installation efficiencies, positions it as a preferred solution for industries prioritizing sustainability and longevity. By choosing this liner, stakeholders invest in a future-proof barrier that safeguards resources and ecosystems for generations.