Why HDPE Pond Liner Is the Best Choice for Fish Farming

1.Waterproofing: Excellent impermeability to stop leakage.

2.UV Resistance: Durable under strong sunlight and weather.

3.Safety: Non-toxic material safe for all fish species.

4.Strength: High puncture and tear resistance.

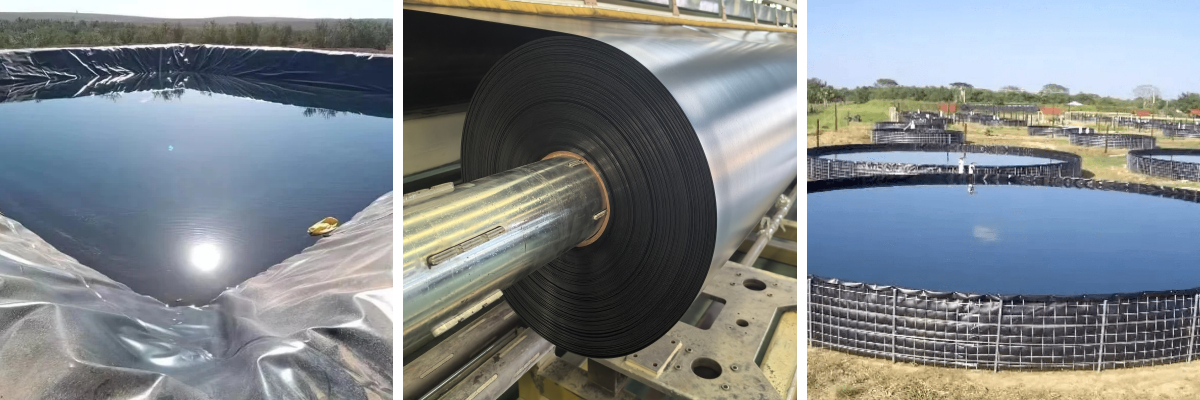

5.Easy Installation: Wide rolls for quick setup.

6.Long Lifespan: Low maintenance and long-term durability.

Fish farming has expanded rapidly in recent years as demand for high-quality aquatic products continues to grow. As farmers look for more reliable and efficient ways to maintain water quality and improve production, the choice of pond liner has become a critical factor. Among all available lining materials, High-Density Polyethylene (HDPE) pond liners have emerged as the preferred solution for modern aquaculture projects—from small backyard ponds to large commercial fish farms. Their strength, durability, and long-term performance make them a smart investment for anyone looking to build a stable and profitable fish farming environment.

Superior Waterproofing to Maintain Stable Water Levels

One of the biggest advantages of HDPE pond liners is their exceptional impermeability. Fish farming requires consistent water levels to maintain healthy growing conditions and protect species from stress caused by sudden water fluctuations. HDPE liners are engineered to prevent seepage even in challenging soil or rocky environments. By creating a stable waterproof barrier, they help farmers avoid water loss, reduce pumping costs, and maintain the ideal water depth for fish growth. This controlled environment directly contributes to a healthier and more predictable production cycle.

Long-Term Durability in Harsh Aquaculture Conditions

Pond liners are constantly exposed to sunlight, chemicals, fluctuating temperatures, and biological elements. Unlike traditional clay ponds or lower-grade plastic liners, HDPE pond liners are manufactured to withstand these harsh conditions for many years. They resist cracking, aging, UV radiation, and chemical corrosion—problems that often cause premature failure in other lining materials. For fish farmers, this means fewer repairs, minimal downtime, and long-term cost savings. When properly installed, HDPE liners can last well over a decade, making them a highly economical choice over the lifespan of a fish farm.

Safe and Non-Toxic Material for Aquatic Life

Safety is a top priority in fish farming. HDPE pond liners are made from 100% virgin raw materials, ensuring they are free of harmful chemicals that could contaminate the water or affect fish health. This material is widely recognized for its food-grade safety and is used in various industries that require strict environmental protection. Because HDPE is inert, it does not release pollutants into the pond, helping maintain high water quality levels and supporting the healthy growth of fish, shrimp, and other aquatic species. This is especially important for farms producing fish for human consumption or export.

High Tensile Strength and Resistance to Puncture

Aquaculture ponds are often built in areas where the soil contains sharp stones, roots, or debris that can puncture a weak liner. HDPE pond liners offer excellent tensile strength and resistance to puncture, making them suitable for both lined and unlined excavation sites. Farmers can install the liners with confidence, knowing that the material will stay intact even under pressure from water loads or external forces. This strength also reduces the need for additional protective layers, making installation faster and more cost-effective.

Cost-Effective Option for Small and Large Fish Farms

Cost is an important consideration when constructing or expanding a fish farm. While HDPE pond liners may require a slightly higher upfront investment compared to PVC or LDPE materials, their long lifespan, minimal maintenance needs, and strong performance make them far more economical over time. Because HDPE does not easily tear, degrade, or require frequent repair, farmers save significantly on replacement and labor costs. For large-scale projects, HDPE liners are available in extra-wide rolls—up to 10 meters or more—reducing the number of welding seams and speeding up construction time.

Easy Installation and Customization

Another major benefit of HDPE pond liners is the flexibility offered during installation. They can be customized to suit any pond shape or size, making them suitable for fish farms with irregular layouts or multiple pond units. The material is lightweight enough for easy handling but strong enough to remain stable once deployed. Modern welding techniques ensure strong, reliable seams that are highly resistant to leaks. Whether building a brand-new pond or rehabilitating an old one, HDPE liners offer a straightforward installation process that minimizes construction delays.

Improved Water Quality Management

Clean and stable water conditions are essential for high-yield fish farming. HDPE liners help maintain water quality by preventing soil contamination, nutrient loss, and bacterial accumulation often seen in unlined earthen ponds. Because the liner creates a smooth barrier, it eliminates direct contact between the pond water and the soil, reducing the risk of harmful elements seeping into the water. The smooth surface also makes the pond easier to clean and disinfect, helping maintain a healthier environment and reducing disease outbreaks among fish populations.

Supports Higher Stocking Density and Yield

With HDPE pond liners, farmers can maintain a more controlled farming environment, allowing for higher stocking densities. Water parameters can be adjusted precisely, oxygenation systems can operate more efficiently, and the clean pond bottom reduces stress on fish. These conditions promote better feeding behavior, faster growth, and improved survival rates. As a result, farms using HDPE liners often achieve higher production output compared to traditional earth ponds.

Environmentally Friendly and Recyclable

HDPE pond liners align well with sustainable aquaculture practices. The material is fully recyclable, helping reduce environmental impact once the liner reaches the end of its service life. Additionally, by preventing water and soil contamination, HDPE liners help protect local ecosystems and groundwater resources. Many agricultural and aquaculture standards now encourage or require the use of environmentally safe lining materials, making HDPE a responsible and forward-thinking choice.

No. | Item | Unit | Index | ||||||||

1 | Thickness | mm | 0.30 | 0.50 | 0.75 | 1.00 | 1.25 | 1.50 | 2.00 | 2.50 | 3.00 |

2 | Density | g/cm3 | ≧0.940 | ||||||||

3 | Tensile yield strength | N/mm | ≧4 | ≧7 | ≧10 | ≧13 | ≧16 | ≧20 | ≧26 | ≧33 | ≧40 |

4 | Tensile breaking strength | N/mm | ≧6 | ≧10 | ≧15 | ≧20 | ≧25 | ≧30 | ≧40 | ≧50 | ≧60 |

5 | Yield elongation | % | - | - | - | ≧11 | |||||

6 | Break Elongation | % | ≧600 | ||||||||

7 | Right-angle Tearing strength | N | ≧34 | ≧56 | ≧84 | ≧115 | ≧140 | ≧170 | ≧225 | ≧280 | ≧340 |

8 | Puncture strength | N | ≧72 | ≧120 | ≧180 | ≧240 | ≧300 | ≧360 | ≧480 | ≧600 | ≧720 |

9 | Carbon black content | % | 2.0~3.0 | ||||||||

10 | Dispersion of carbon black | - | There is not more than one level 3 in 10 data, and level 4 and level 5 are not allowed to exist. | ||||||||

11 | Oxidation induction time | min | ≧60 | ||||||||

12 | Low temperature impact embrittlement properties | - | Pass | ||||||||

13 | Water vapor permeability coefficient | g.cm/ (cm2.s.Pa) | ≦1.0*10-13 | ||||||||

14 | Dimensional stability | % | ±2.0

| ||||||||

Note | Technical performance indicators for thickness specifications not listed in the table are required to be performed by interpolation. | ||||||||||

A Proven Solution for All Types of Aquaculture Projects

From freshwater tilapia ponds to intensive shrimp farming systems and high-value ornamental fish ponds, HDPE pond liners are versatile enough to meet a wide range of aquaculture needs. Their combination of safety, strength, and long-term performance makes them suitable for projects of any size. Many commercial operations and government-supported aquaculture projects have adopted HDPE liners due to their consistent results and excellent return on investment.